Preparation method of seed crystal for superalloy single crystal blade with precise controllable three-dimensional orientation

A high-temperature alloy, three-dimensional orientation technology, applied in the direction of single crystal growth, single crystal growth, metal processing equipment, etc., to achieve the effects of good grain integrity, production cost savings, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Single crystal test bar design

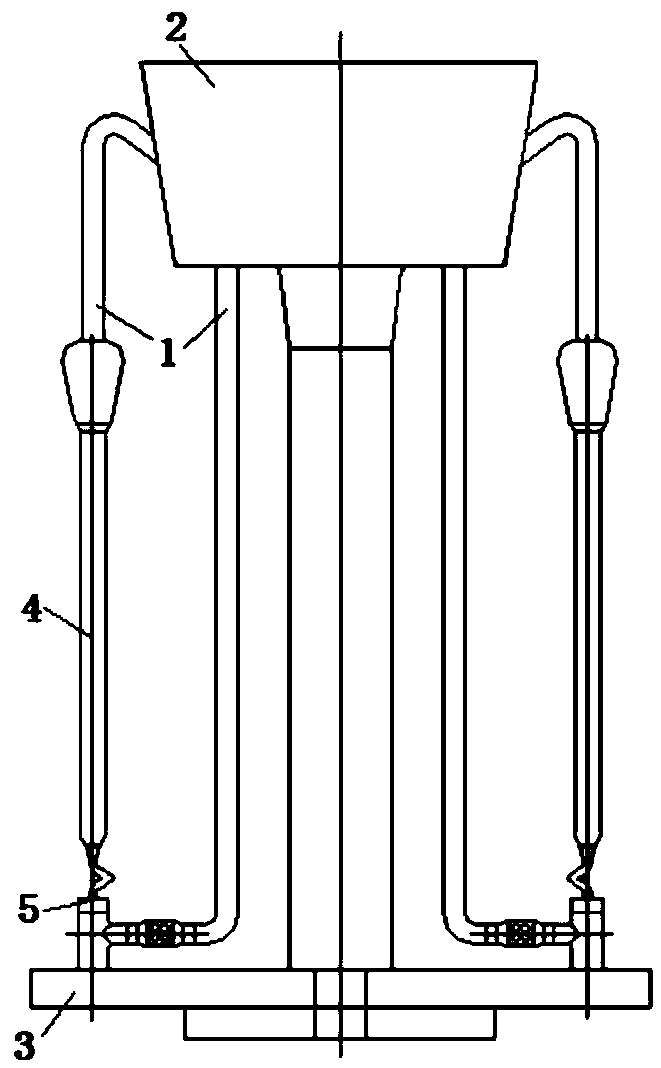

[0043] Test rod design scheme such as figure 1 Make a set of precision casting module, which consists of five parts: test rod 4, crystal selector 5, sprue cup 2, pouring system 1 and chassis 3.

[0044] 2. Wax making

[0045] Control the wax temperature at 60°C and inject the wax into the single crystal test rod and the sprue mold under the condition of the wax injection pressure of 0.3MPa to obtain the part wax mold, the sprue cup wax mold, the chassis wax mold, the sprue wax mold, and the selected wax mold. crystal wax mold;

[0046] (3) Wax model tree

[0047] Combine parts wax molds, sprue cup wax molds, chassis wax molds, sprue wax molds and crystal selector wax molds according to the design scheme;

[0048] 4. Shell making

[0049] A 5mm-thick investment casting mold shell was coated on the surface of the wax pattern group, then steam dewaxed at 120°C, and baked at 600°C for 1 hour to obtain a single crystal oriented precis...

Embodiment 2

[0062] 1. Single crystal test bar design

[0063] Test rod design scheme such as figure 1 Make a set of precision casting module, which is composed of five parts: test rod part 4, crystal selector 5, sprue cup 2, pouring system 1 and chassis 3.

[0064] 2. Wax making

[0065] The temperature of the wax is controlled at 120°C, and the wax injection pressure is 20MPa and injected into the single crystal test rod and the sprue mold to obtain the part wax mold, the sprue cup wax mold, the chassis wax mold, the sprue wax mold, and the selected wax mold. Crystal wax mold.

[0066] 3. Wax model tree

[0067] Combining the part wax mold, sprue cup wax mold, chassis wax mold, sprue wax mold and crystal selector wax mold according to the design scheme.

[0068] 4. Shell making

[0069] A 15mm-thick investment casting mold shell was coated on the surface of the wax pattern group, and then steam dewaxed at 200°C, and baked at 900°C for 3 hours to obtain a single crystal oriented prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com