Vehicle anti-collision beam and manufacturing method thereof

A manufacturing method and anti-collision beam technology, which is applied to vehicle parts, bumpers, transportation and packaging, etc., can solve the problems of large impact force of the vehicle body and single protection method, and achieve simple operation, easy disassembly, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

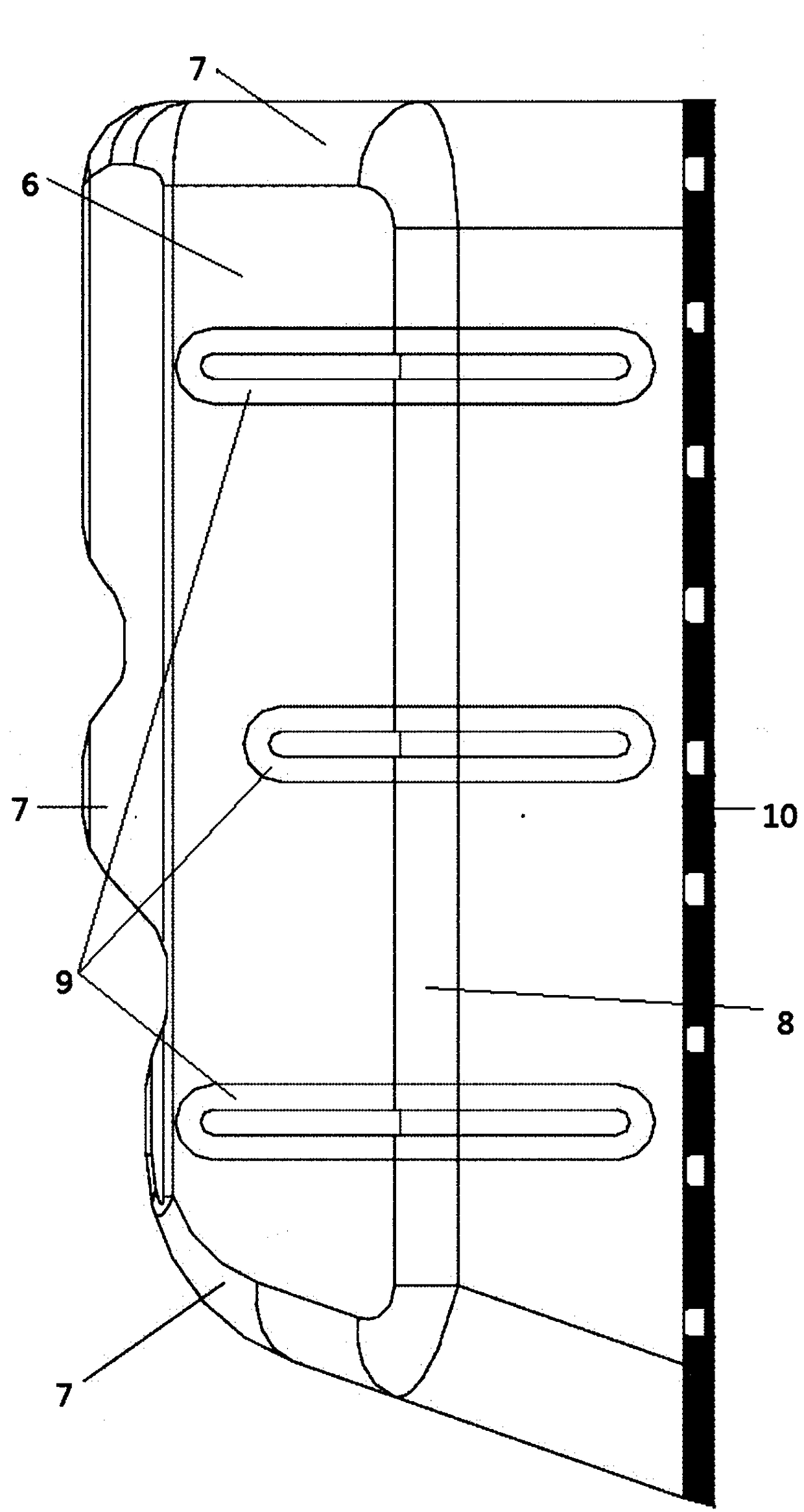

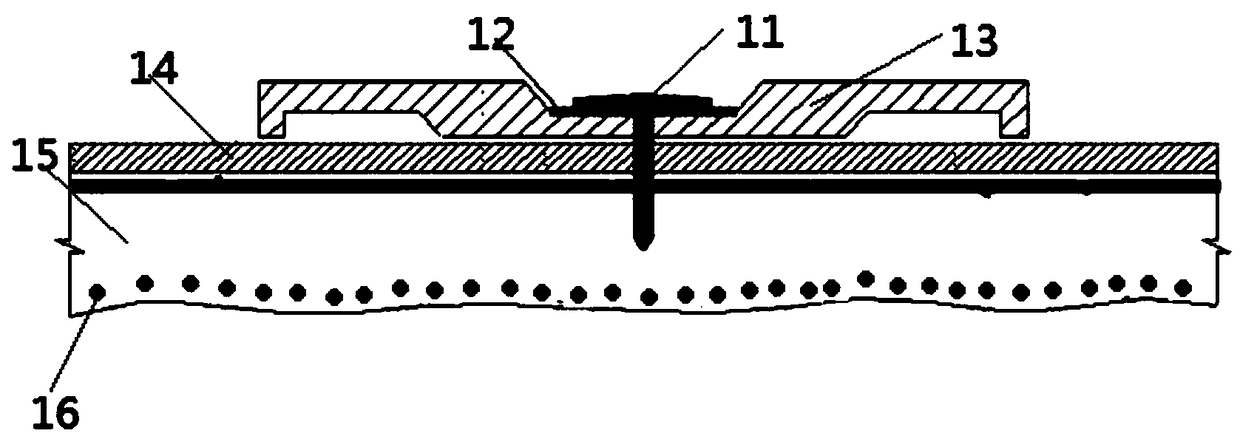

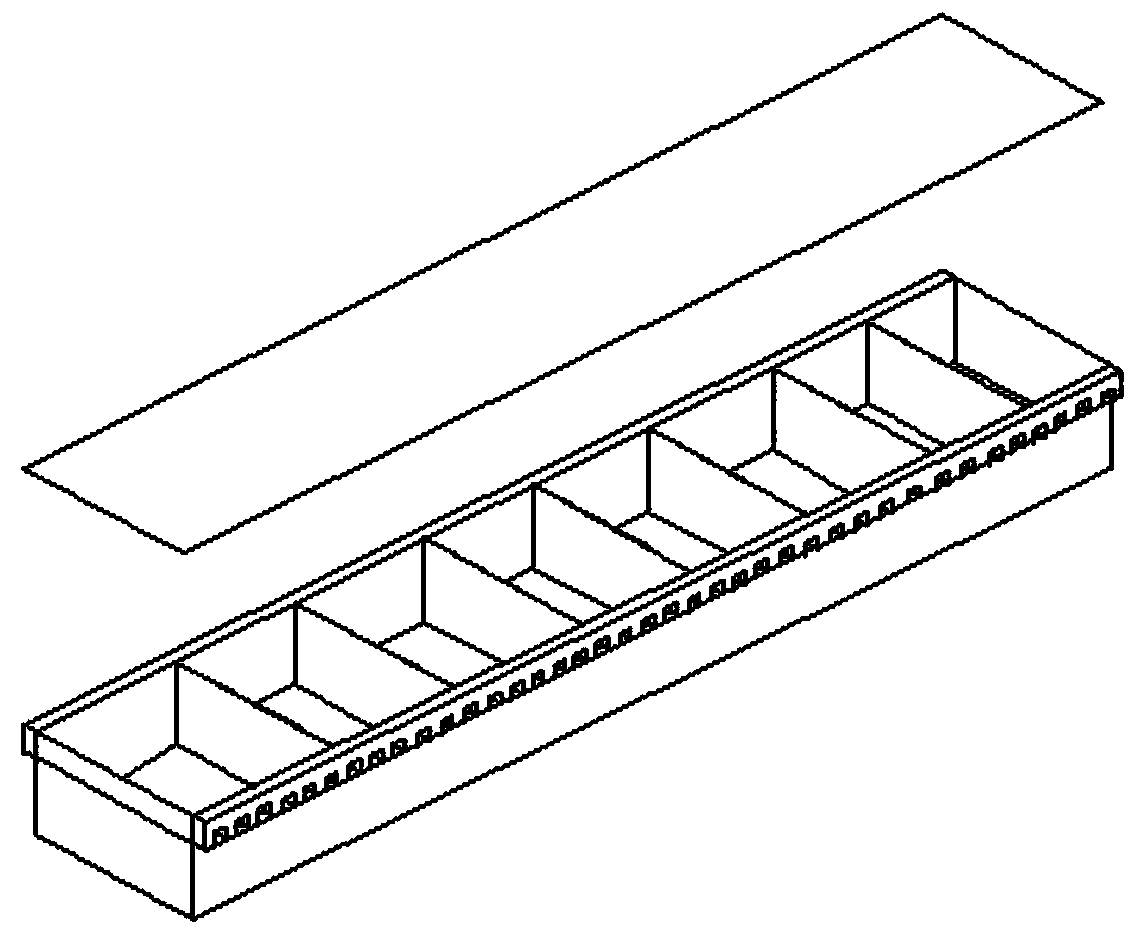

[0027] An anti-collision beam for a vehicle, characterized in that it includes a plastic bumper shell, an energy-absorbing buffer layer, a reinforcing beam, an energy-absorbing box and bolts; the plastic bumper shell, the energy-absorbing buffer layer, and the reinforcing beam Connected in sequence, the two ends of the inward side of the reinforcing beam are each provided with an energy-absorbing box, and the energy-absorbing box is connected to the reinforcing beam and the body of the vehicle body.

[0028]The bumper shell is a shell with an open back, which is composed of an aluminum shell, a plastic foam protective layer, a reinforcing rib, an annular metal fixing frame and a shell fixing groove, and the arcs on the front surface, top surface and bottom surface of the bumper shell There is a plastic foam protective layer inside the bumper, which is made of plastic foam, which can provide a certain amount of cushioning for the pedestrian's legs when the vehicle collides with ...

Embodiment 2

[0034] A method for manufacturing an anti-collision beam for a vehicle, characterized by the steps of: (1) preparing a plastic bumper shell through the processes of compression molding, extrusion molding, injection molding and blow molding; Beam; (3) Carbon fiber composite rubber material is used to make an energy-absorbing buffer layer of the same size as the reinforced beam, and the plastic bumper shell, energy-absorbing buffer layer and reinforced beam are connected by bolts; (4) at both ends of the inner side of the reinforced beam Connect the two crash boxes and connect to the mounting plate through the crash box.

[0035] The process of high-pressure hot stamping in step (2) is as follows: heat the boron steel to 950°C, hold it for 5 minutes, and then quickly transfer it from the heating furnace to the mold for forming. Its full martensitization is beneficial to the forming of the sheet metal, and it is quenched after forming to increase the hardness;

[0036] In the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com