Copper alloy with high strength, high conductivity and high plasticity and preparation method thereof

A high-conductivity, high-plasticity technology, applied in the field of alloys, can solve problems such as high strength, high conductivity and high plasticity, achieve good strength and conductivity, and ensure safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

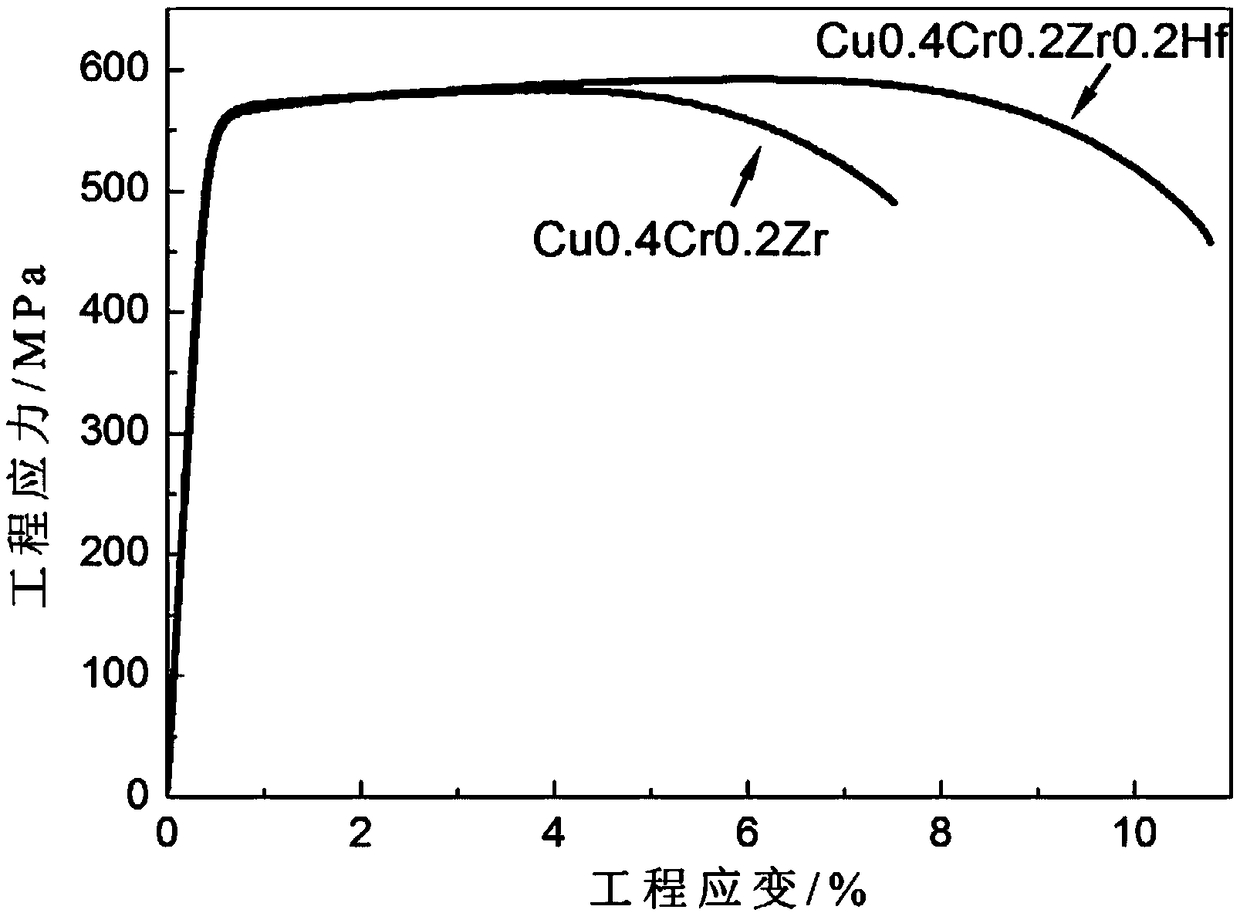

Embodiment 1

[0029] This embodiment discloses a method for preparing a copper alloy with high strength, high conductivity and high plasticity, including the following steps:

[0030] 1. The electrolytic pure copper is electrolytically polished to remove oxide scale and other surface materials, the raw materials are cleaned with anhydrous ethanol through ultrasonic waves, and dried in a blast drying oven at 50°C for 30 minutes;

[0031] 2. Ingredients, the total weight is 2500g, the mass fraction of Cr is 0.4% (10g), the mass fraction of Zr is 0.2% (5g), the mass fraction of Hf is 0.2% (5g), the mass ratio of Zr to Hf is 1, the Cu particles in the master alloy are 60g, The rest is Cu block (2420g) for weighing ingredients;

[0032] 3. Zr and Hf elements are added to the copper melt in the form of a master alloy, and the master alloy is prepared using a vacuum non-consumable electric arc furnace, where the mass ratio of Cu particles (60g) to the total Zr and Hf raw materials (10g) is 6, repeated S...

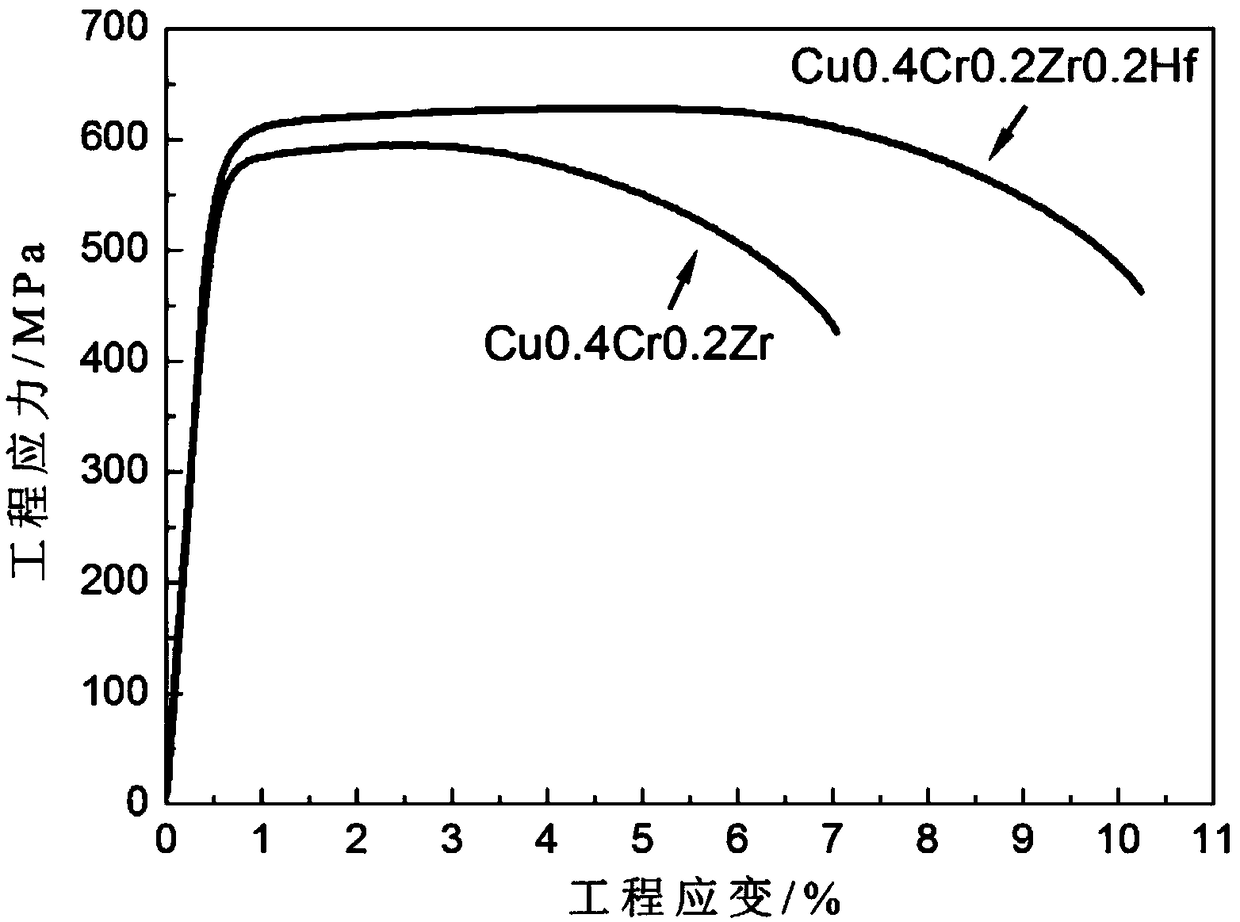

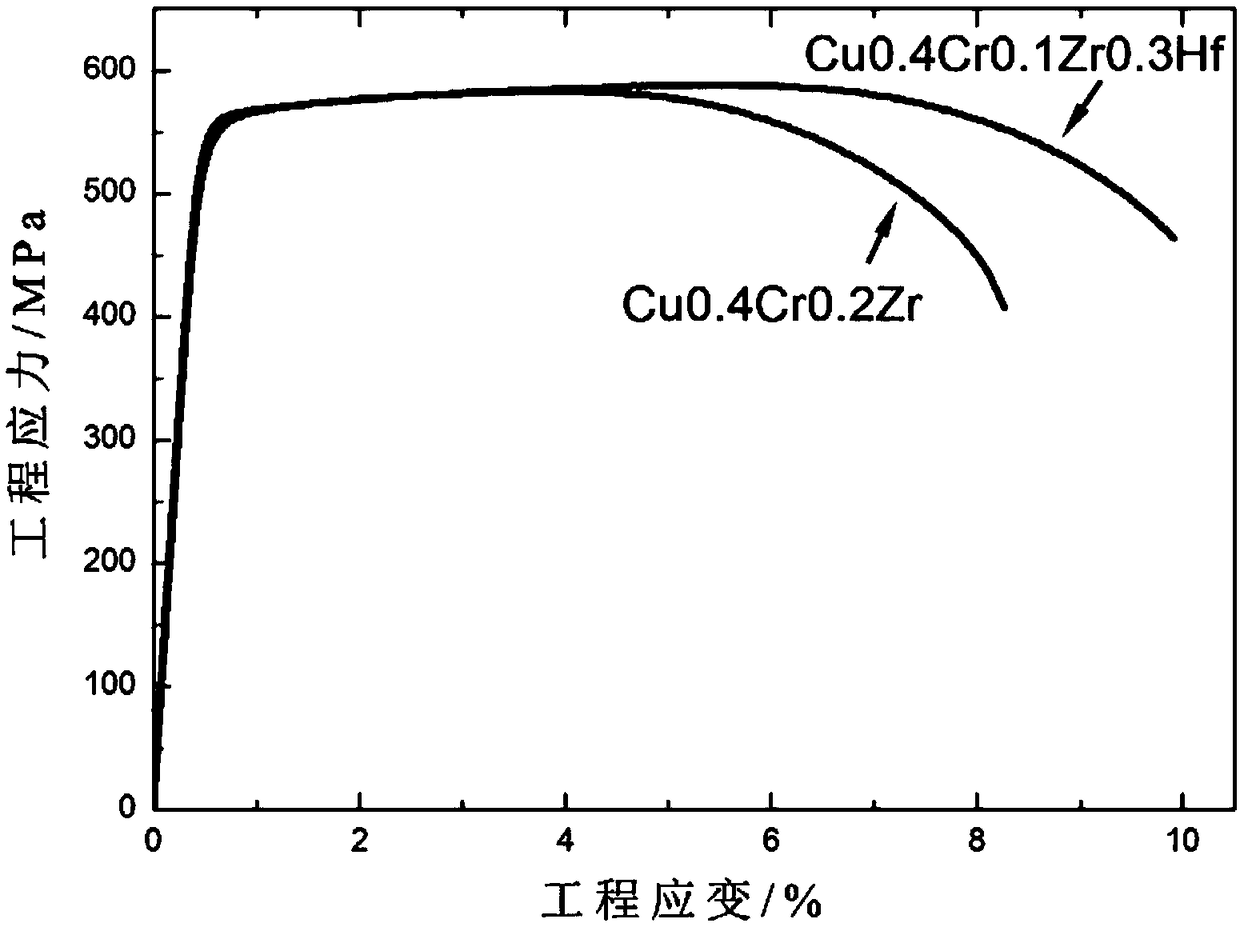

Embodiment 2

[0045] This embodiment discloses another method for preparing a copper alloy with high strength, high conductivity and high plasticity, including the following steps:

[0046] 1. The electrolytic pure copper is electrolytically polished to remove oxide scale and other surface materials, the raw materials are cleaned with anhydrous ethanol through ultrasonic waves, and dried in a blast drying oven at 50°C for 30 minutes;

[0047] 2. Ingredients, the total weight is 2500g, the mass fraction of Cr is 0.4% (10g), the mass fraction of Zr is 0.1% (2.5g), the mass fraction of Hf is 0.3% (7.5g), the mass ratio of Zr to Hf is 0.33, Cu particles in the master alloy 60g, the rest is Cu block (2420g) for weighing ingredients;

[0048] 3. Zr and Hf elements are added to the copper melt in the form of a master alloy, and the master alloy is prepared using a vacuum non-consumable electric arc furnace, where the mass ratio of Cu particles (60g) to the total Zr and Hf raw materials (10g) is 6, repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com