Ion Nitriding Equipment for Titanium Alloy Parts

A technology of nitriding tooling and titanium alloys, applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve the problems of affecting the geometric accuracy of parts, out of tolerance of parts, large temperature fluctuations, etc., to improve production Efficiency, reduction of deformation difference and degree of deformation, effect of electric field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

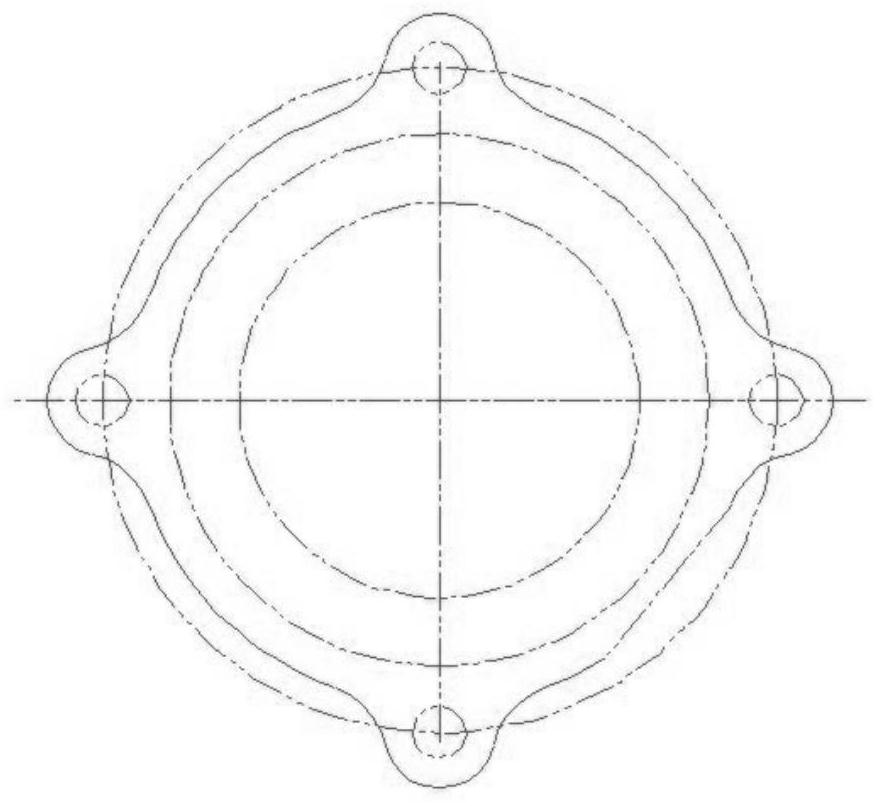

[0018] Take a certain specification of titanium alloy bearing bushing as an example, the bushing material is TA7, the ion nitriding temperature of this part is 840℃, and the bushing size is shown in the appendix figure 1 shown.

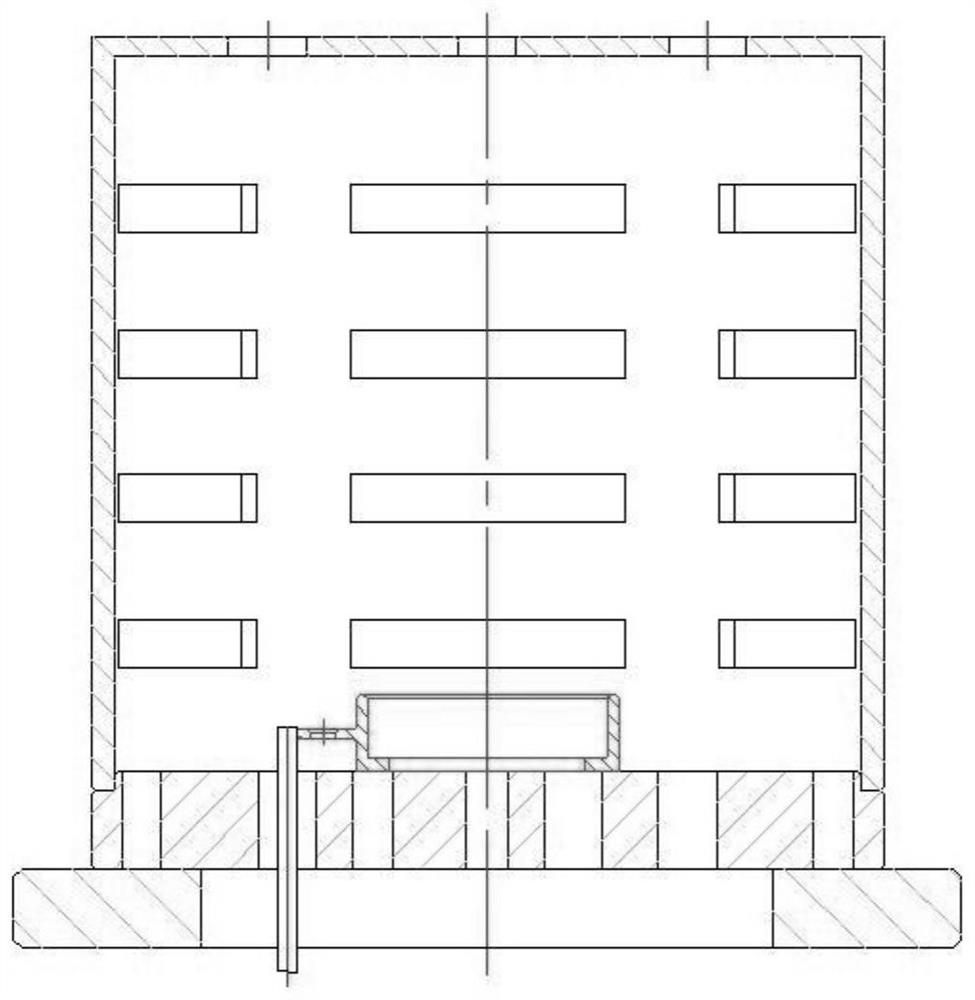

[0019] For optional tooling, please refer to figure 2 , Make sure to use TC4 material tooling of φ260mm×150mm, and drill holes of φ30mm in the center of the upper and lower bottoms of the tooling. See the attachment for other surface opening methods of the tooling. figure 2 .

[0020] There are several grooves on the wall of the cylinder, and the bottom surface is provided with a centrally symmetric array hole. The several grooves are parallel to each other in the longitudinal direction and on the same circumference in the transverse direction. By this method, the nitrogen-containing particles in the ion nitriding furnace can be uniformly entered into the tooling. internal.

[0021] The titanium alloy bearing bushing is placed at the geometric ce...

Embodiment 2

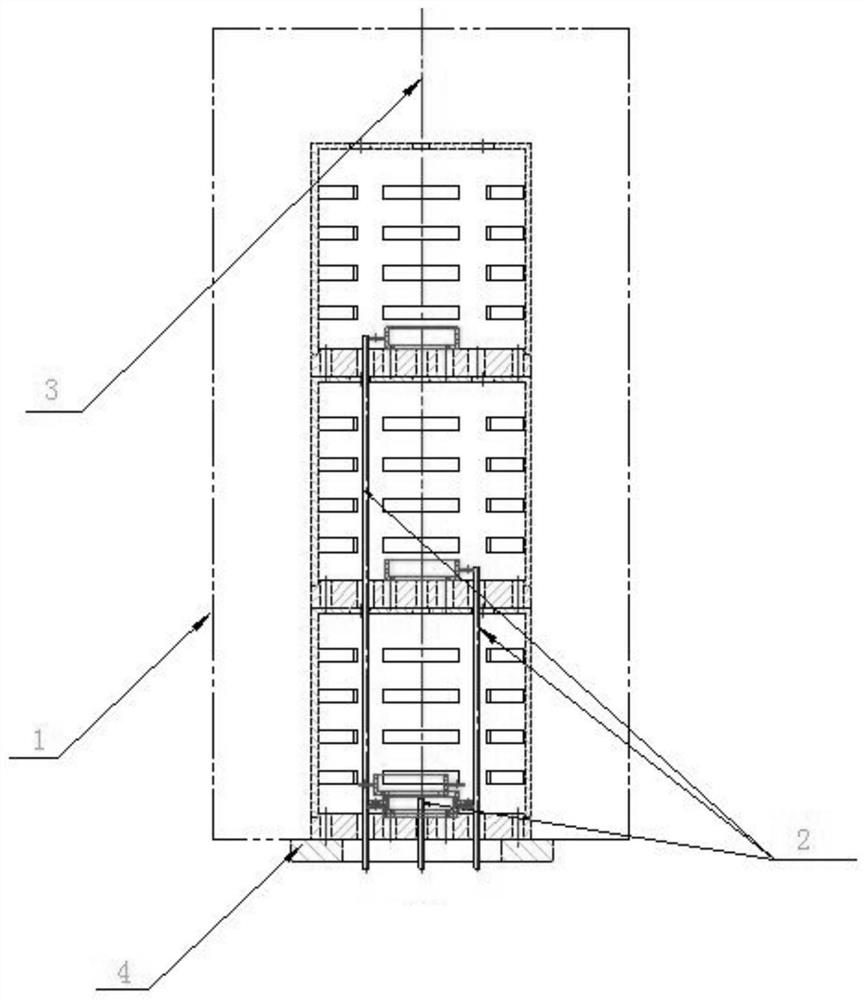

[0024] Take the titanium alloy bearing bushing of the same specification as an example, the bushing material is TA7, and the ion nitriding temperature of this part is 840℃. In order to improve production efficiency, combined with the effective working area height of the ion nitriding furnace (φ600mm×800mm), choose to use 3 tooling, the tooling and the tooling are in direct contact, please refer to image 3 and Figure 4 .

[0025] The titanium alloy bearing bushing, the tooling and the three cathode discs are concentric, which can effectively ensure that the parts are heated evenly in the ion nitriding furnace, and improve the local uniformity of the furnace temperature in each tooling.

[0026] In addition to the temperature-controlling thermocouple, insert two temperature-measuring thermocouples upward through the hole of the tooling base plate, and enter into the accessories of the upper two tooling parts for temperature measurement. The temperature-controlling and temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com