Distributed multi-point synchronous electro-hydraulic servo control system of tunnel model test platform

A test platform and tunnel model technology, applied to servo motors, servo motor components, fluid pressure actuation system components, etc., can solve problems such as segment damage and deformation effects, and achieve the effect of accurate control and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

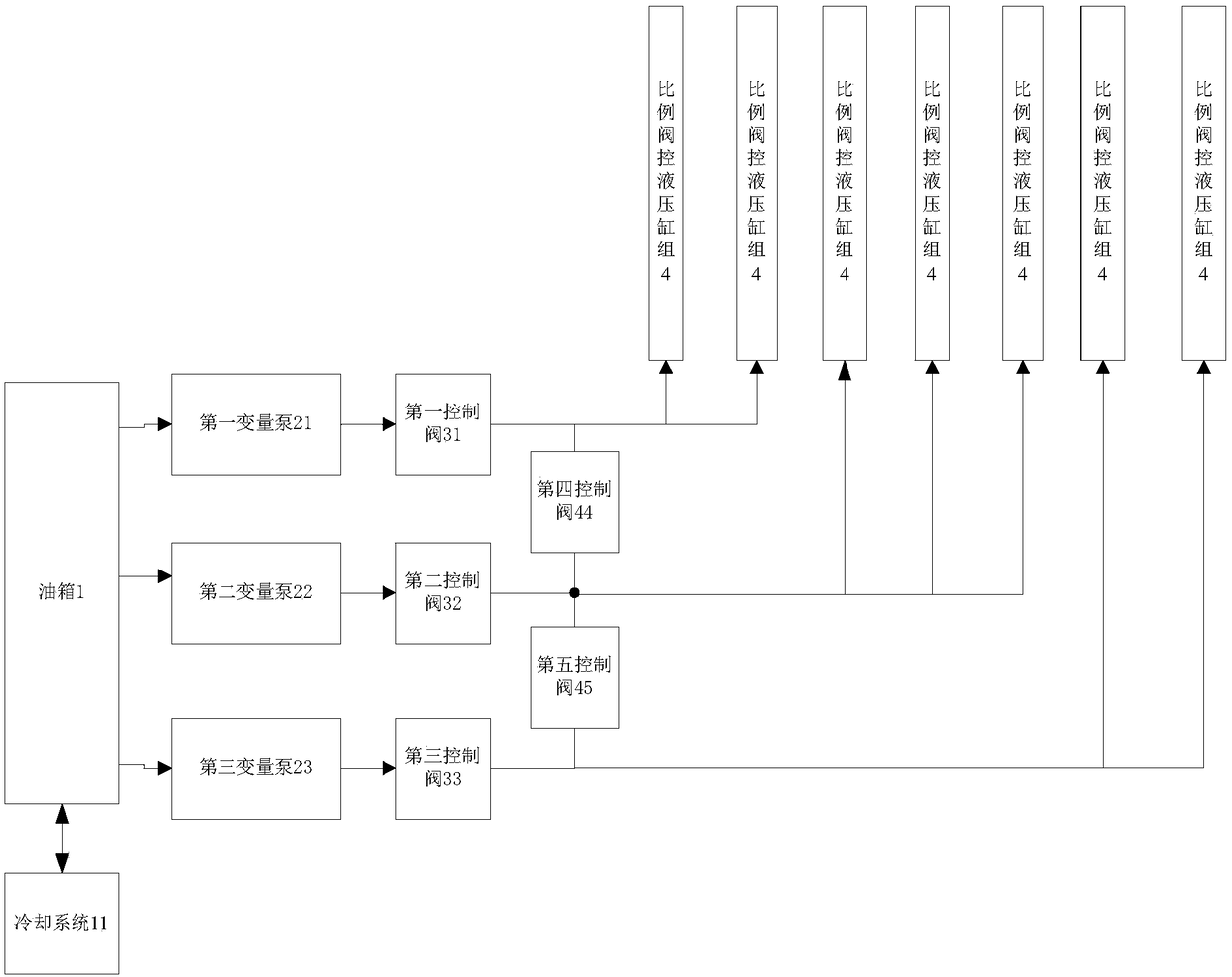

[0010] Embodiment 1: The distributed multi-point synchronous electro-hydraulic servo control system of the tunnel model test platform, including a control module, an oil tank 1 with a cooling system 11, a first variable pump 21, a second variable pump 22, and a third variable pump 23 , the first control valve 31, the second control valve 32, the third control valve 33, the fourth control valve 34, the fifth control valve 35 and the execution module, the execution module includes seven support rings for supporting the experimental tube (Fig. not shown), each ring frame is provided with a group of proportional valve-controlled hydraulic cylinders 4, and each group of proportional valve-controlled hydraulic cylinders 4 includes a plurality of proportional valve-controlled hydraulic cylinders for exerting effects on the experimental segments (not shown in the figure ), the oil outlet of the oil tank 1 communicates with the inlet of the first variable displacement pump 21, the inlet...

Embodiment 2

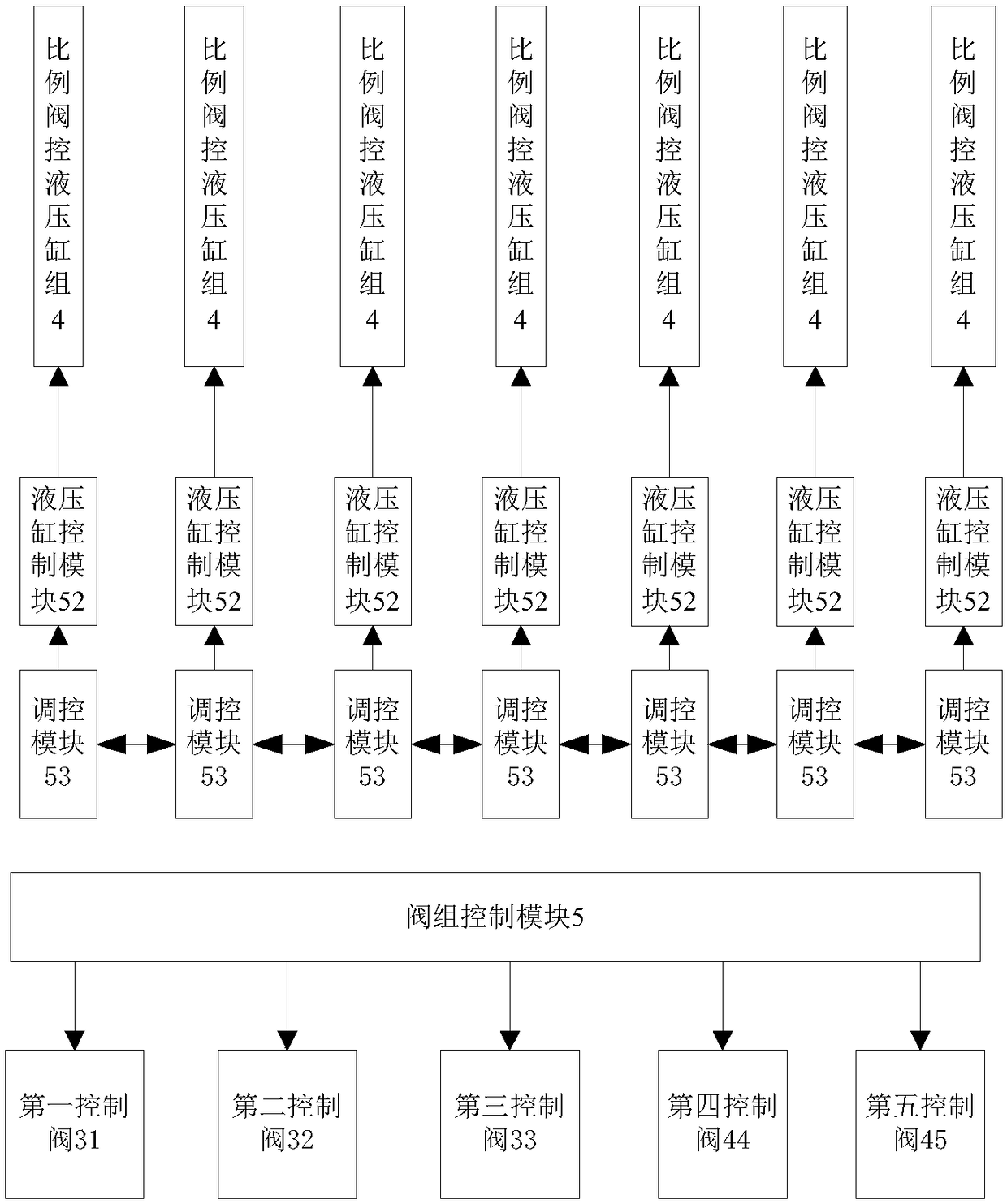

[0011] Embodiment 2: the rest is the same as Embodiment 1, the difference is that each hydraulic cylinder control module 52 is provided with a regulation module 53, and each regulation module 53 is used to read the The load information and displacement information of the other six groups of proportional valve-controlled hydraulic cylinders 4 other than one group of proportional valve-controlled hydraulic cylinders 4 are obtained according to the preset program and the corresponding control signals are sent to the corresponding hydraulic cylinder control modules 52, and then the hydraulic cylinder control module 52 controls the load state and displacement state of the corresponding proportional valve-controlled hydraulic cylinder group 4 according to the regulation signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com