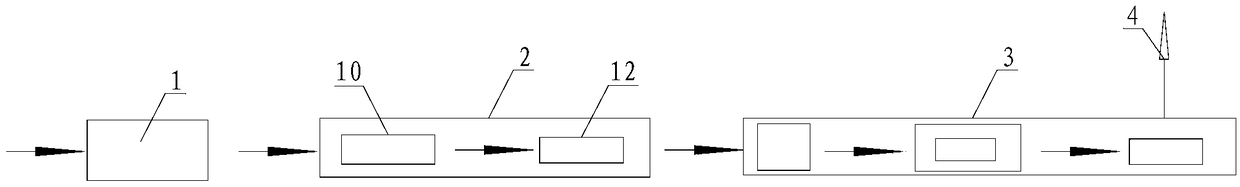

Online sampling system for measuring total S content in coke oven gas

A coke oven gas and sampling system technology, applied in sampling, measuring device, sampling device and other directions, can solve the problems of sulfide sampling and detection absorption not involved, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

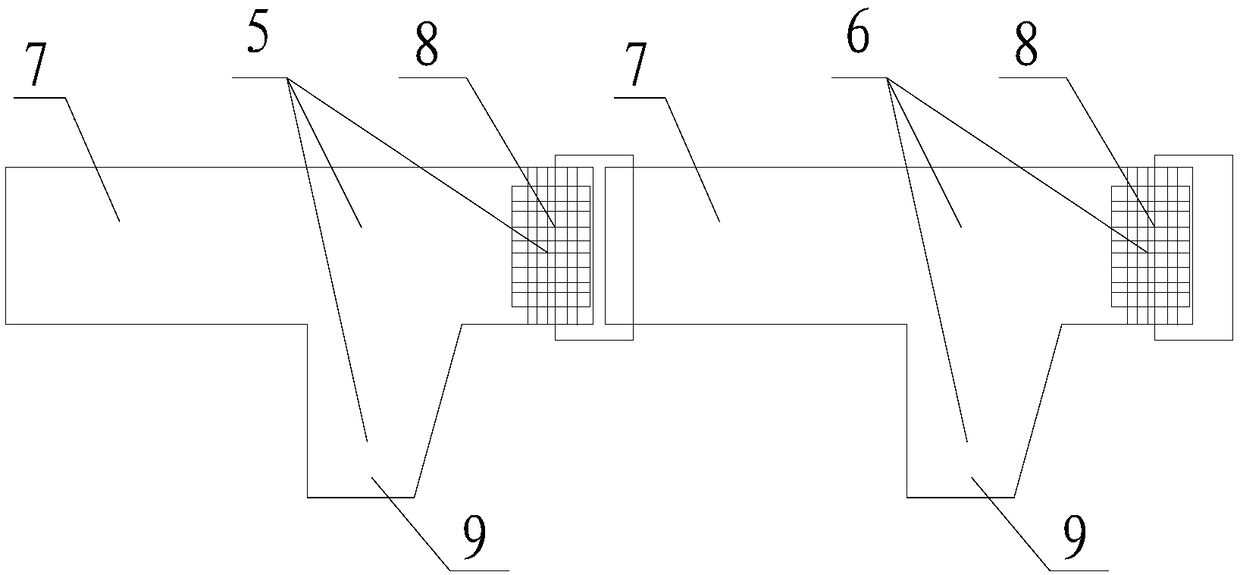

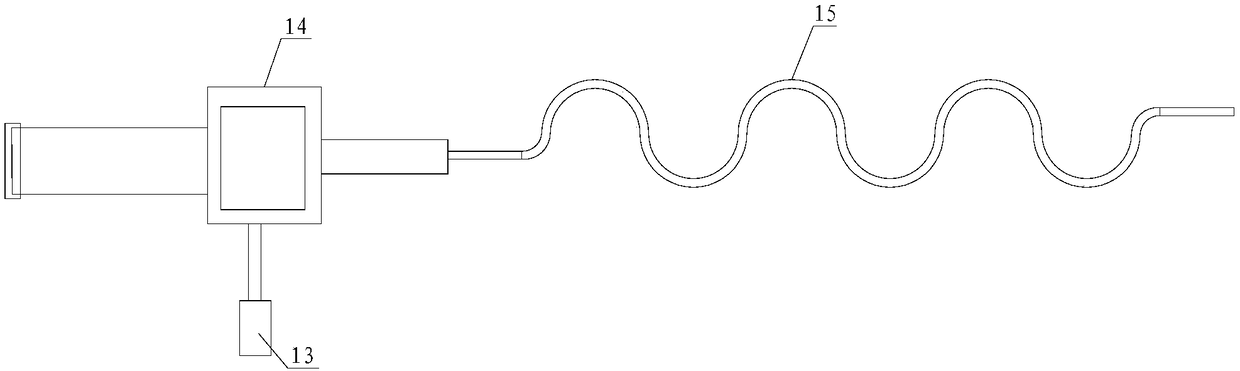

Method used

Image

Examples

Embodiment 1

[0024] A coking company has 3 coke ovens, with an annual output of 3 million tons of coke and 1.6 billion m of coke oven gas 3 , through this sampling device and detection method, the sulfide in the imported coke oven gas is sampled and detected. The gas volume is 200L, and the measured hydrogen sulfide content is 4.81g / m 3 , carbon disulfide content 805mg / m 3 , COS content 496mg / m 3 , other sulfides are small, negligible, that is, the total sulfur content is 5.47g / m 3 , and on-site desulfurization product sulfur content analysis, the result error is within 10%.

[0025] After the coke oven gas is purified by the desulfurization device, the sulfide in the exported coke oven gas is sampled and tested. The gas volume is 200L, and the measured hydrogen sulfide content is 210mg / m 3 , carbon disulfide content 97mg / m 3 , COS content 62mg / m 3 , by calculating the total sulfur content, it is 197.8mg / m 3 , slightly higher than the SO after combustion of the gas-fired boiler 2 Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com