Composite glassy carbon electrode and preparation method and application thereof

A glassy carbon electrode and electrode technology, which is applied in the field of composite glassy carbon electrode and its preparation, can solve problems such as weak binding force, and achieve the effects of low overpotential, wide electrochemical window, low detection potential and overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

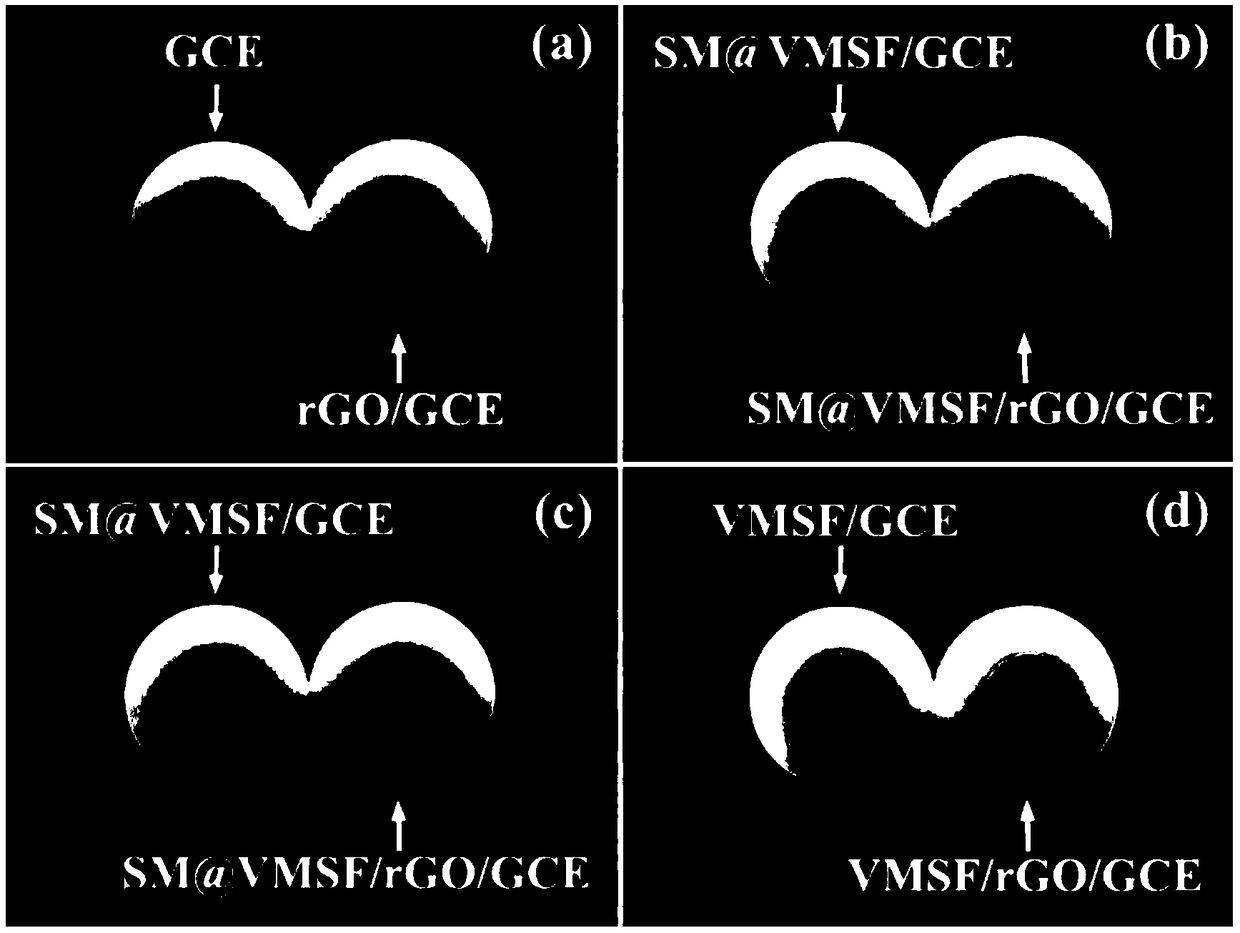

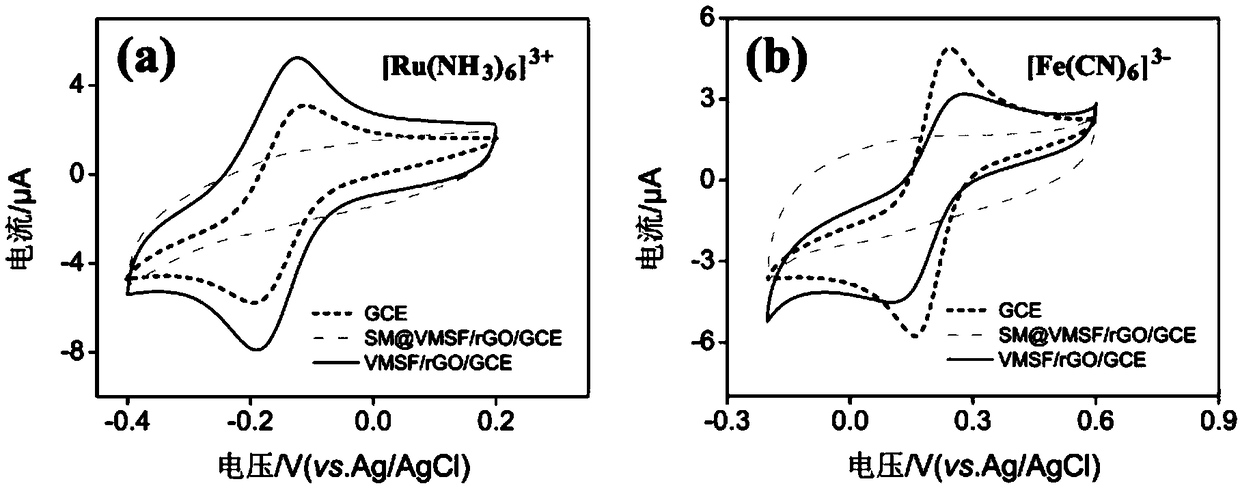

[0063] 1. A method for utilizing reduced graphene oxide as an adhesion layer to realize the stable modification of a mesoporous silicon dioxide homoporous film on a glassy carbon electrode substrate, comprising the following steps:

[0064] (1) Decorate the reduced graphene oxide on the surface of the glassy carbon electrode;

[0065] Wherein reduced graphene oxide (rGO) adopts the method for chemically reducing graphene oxide to prepare, specifically as follows:

[0066] Take 8mL graphene oxide dispersion, 32mL ultrapure water, 7μL hydrazine hydrate solution, 120μL ammonia water, stir evenly; react at 85°C for 3 hours. The solution after the reaction was centrifuged at 3000 rpm for 30 minutes, and the supernatant was taken.

[0067] The rGO / GCE electrode was prepared by drop-coating the rGO solution on the glassy carbon electrode:

[0068] Take 10 μL rGO solution, drop-coat it on the glassy carbon electrode, and bake it dry under infrared lamp.

[0069] (2) Preparation of ...

Embodiment 2

[0090] 1. A method for utilizing reduced graphene oxide as an adhesion layer to realize the stable modification of a mesoporous silicon dioxide homoporous film on a glassy carbon electrode substrate, comprising the following steps:

[0091] (1) Decorate the reduced graphene oxide on the surface of the glassy carbon electrode;

[0092] Wherein reduced graphene oxide (rGO) adopts the method for chemically reducing graphene oxide to prepare, specifically as follows:

[0093] Take 10mL graphene oxide dispersion, 30mL ultrapure water, 7μL hydrazine hydrate solution, 130μL ammonia water, stir evenly; react at 85°C for 3 hours. The solution after the reaction was centrifuged at 3000 rpm for 30 minutes, and the supernatant was taken.

[0094] The rGO / GCE electrode was prepared by drop-coating the rGO solution on the glassy carbon electrode:

[0095] Take 10 μL rGO solution, drop-coat it on the glassy carbon electrode, and bake it dry under infrared lamp.

[0096] (2) Preparation of...

Embodiment 3

[0102] 1. A method for utilizing reduced graphene oxide as an adhesion layer to realize the stable modification of a mesoporous silicon dioxide homoporous film on a glassy carbon electrode substrate, comprising the following steps:

[0103] (1) Decorate the reduced graphene oxide on the surface of the glassy carbon electrode;

[0104] Wherein reduced graphene oxide (rGO) adopts the method for chemically reducing graphene oxide to prepare, specifically as follows:

[0105] Take 6 mL of graphene oxide dispersion, 34 mL of ultrapure water, 7 μL of hydrazine hydrate solution, and 120 μL of ammonia water, and stir evenly; react at 85°C for 3 hours. The solution after the reaction was centrifuged at 3000 rpm for 30 minutes, and the supernatant was taken.

[0106] The rGO / GCE electrode was prepared by drop-coating the rGO solution on the glassy carbon electrode:

[0107] Take 10 μL rGO solution, drop-coat it on the glassy carbon electrode, and bake it dry under infrared lamp.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com