Method for immobilization of metal iridium complexes with silicon nanoparticles being coated on electrode

A technology of silicon nanoparticles and immobilized metals, which is applied in the direction of electrodes, electrochemical variables of materials, chemiluminescence/bioluminescence, etc., can solve the problems of long time consumption, easy contamination, unresolved reproducibility and service life, and achieve Effect of small particle size and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

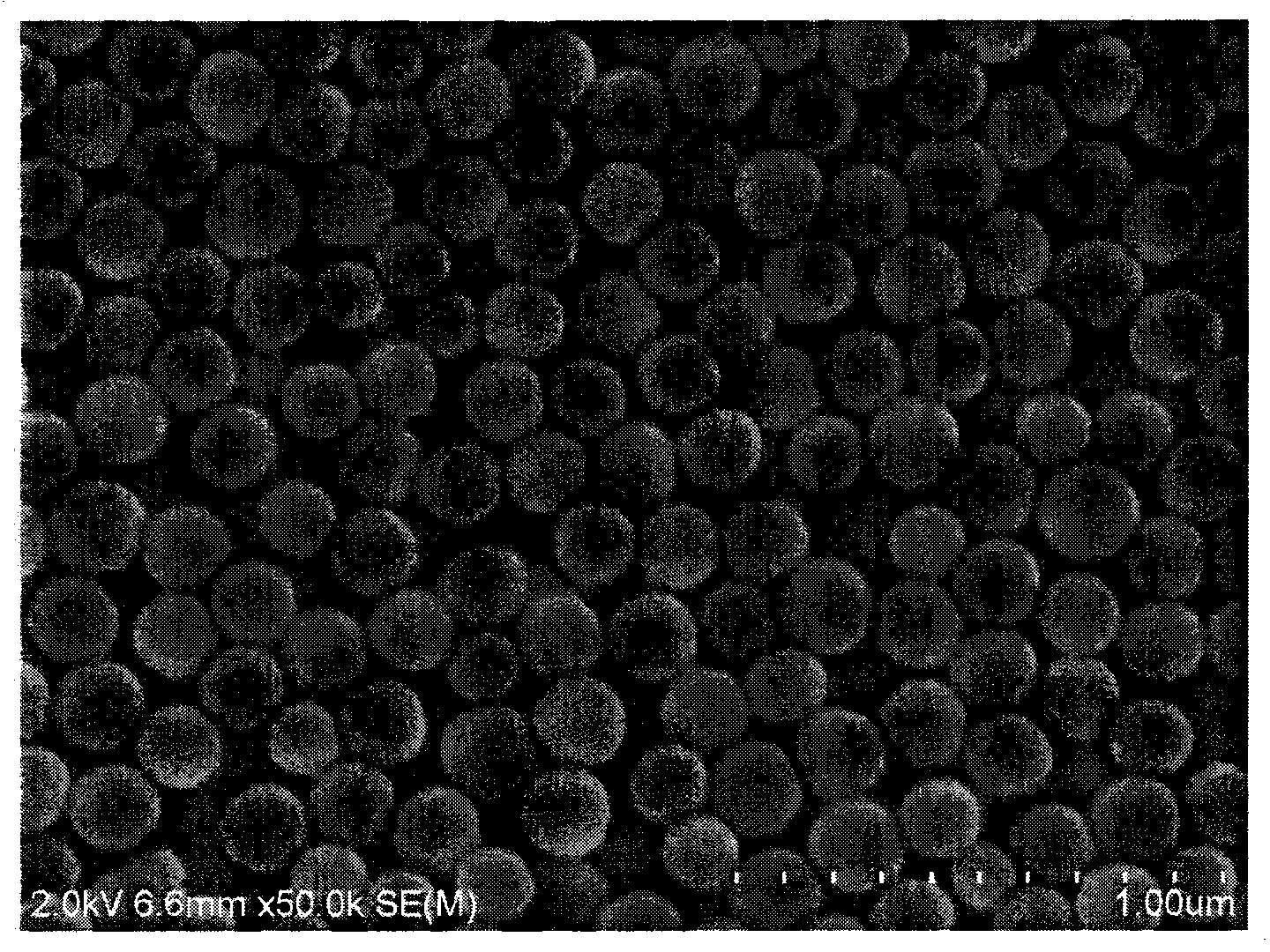

[0017] Example 1. Preparation of sensor: Add 0.44g AOT and 800 μL n-BuOH to 20ml ultrapure water, and stir magnetically to completely dissolve AOT until clear. Pipette 10.08mmol / L (pq) with a pipette 2 Add 100 μl of Ir(acac) in DMSO to the micellar system, and stir magnetically. Add 500 μL of vinyltrimethoxysilane to the micellar system, and stir for 1 h under magnetic force. Finally, 20 μl of concentrated ammonia water was added and magnetically stirred for 20 h to obtain a red silica nanoparticle emulsion doped with iridium complexes. Dialyze with a dialysis bag with a molecular weight cut-off of 12-14KDa for 50 hours, and remove the dialysate obtained by removing AOT and n-BuOH. After dialysis, the silica nanoparticles are evenly dispersed. Use a micro-sampler to pipette 10 μL of the dispersion liquid, drop-coat it on the surface of the glassy carbon electrode, place the electrode in the air to evaporate the solvent, and form a uniform particle on the electrode surface. ...

example 2

[0018] Example 2. Preparation of sensor: 0.44g AOT, 800 μl n-BuOH were added to 20ml ultrapure water, and magnetically stirred to completely dissolve AOT until clear. Pipette 10.08mmol / L (pq) with a pipette 2 100 μl of Ir(acac) in DMSO was added to the micellar system, and magnetically stirred for 1 h. Add 500 μL of vinyltriethoxysilane to the micellar system, and stir magnetically for 20 h. Finally, 20 μl of concentrated ammonia water was added and magnetically stirred for 20 h to obtain a red silica nanoparticle emulsion doped with iridium complexes. Dialyze with a dialysis bag with a molecular weight cut-off of 12-14 KDa for 50 h, and filter the dialysate obtained by removing AOT and n-BuOH with a 0.2 μl microporous membrane. After dialysis, the silica nanoparticles are evenly dispersed. Use a micro-sampler to pipette 10 μL of the dispersion liquid, drop-coat it on the surface of the glassy carbon electrode, place the electrode in the air to evaporate the solvent, and for...

example 3

[0019] Example 3. Preparation of sensor: 0.33g AOT, 600 μl n-BuOH were added to 20ml ultrapure water, and magnetically stirred to completely dissolve AOT until clear. Pipette 10.08mmol / L (pq) with a pipette 2 100 μl of Ir(acac) in DMSO was added to the micellar system, and magnetically stirred for 1 h. Add 500 μL of phenyltrimethoxysilane to the micellar system, and stir for 1 h under magnetic force. Finally, 0.042 g of sodium carbonate was slowly added and magnetically stirred for 20 h to obtain a red silica nanoparticle emulsion doped with iridium complexes. Dialyze with a dialysis bag with a molecular weight cut-off of 12-14 KDa for 50 h, and filter the dialysate obtained by removing AOT and n-BuOH with a 0.2 μl microporous membrane. After dialysis, the silica nanoparticles are evenly dispersed. Use a micro-sampler to pipette 10 μL of the dispersion liquid, drop-coat it on the surface of the glassy carbon electrode, place the electrode in the air to evaporate the solvent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com