Bonding device and method for directly bonding hydrophilic discs

A direct bonding and bonding device technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as re-pollution of the wafer surface, more restrictions on wafer materials, and adverse effects on bonding quality. Achieve low cost, improve bonding quality, and prevent splashing of flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

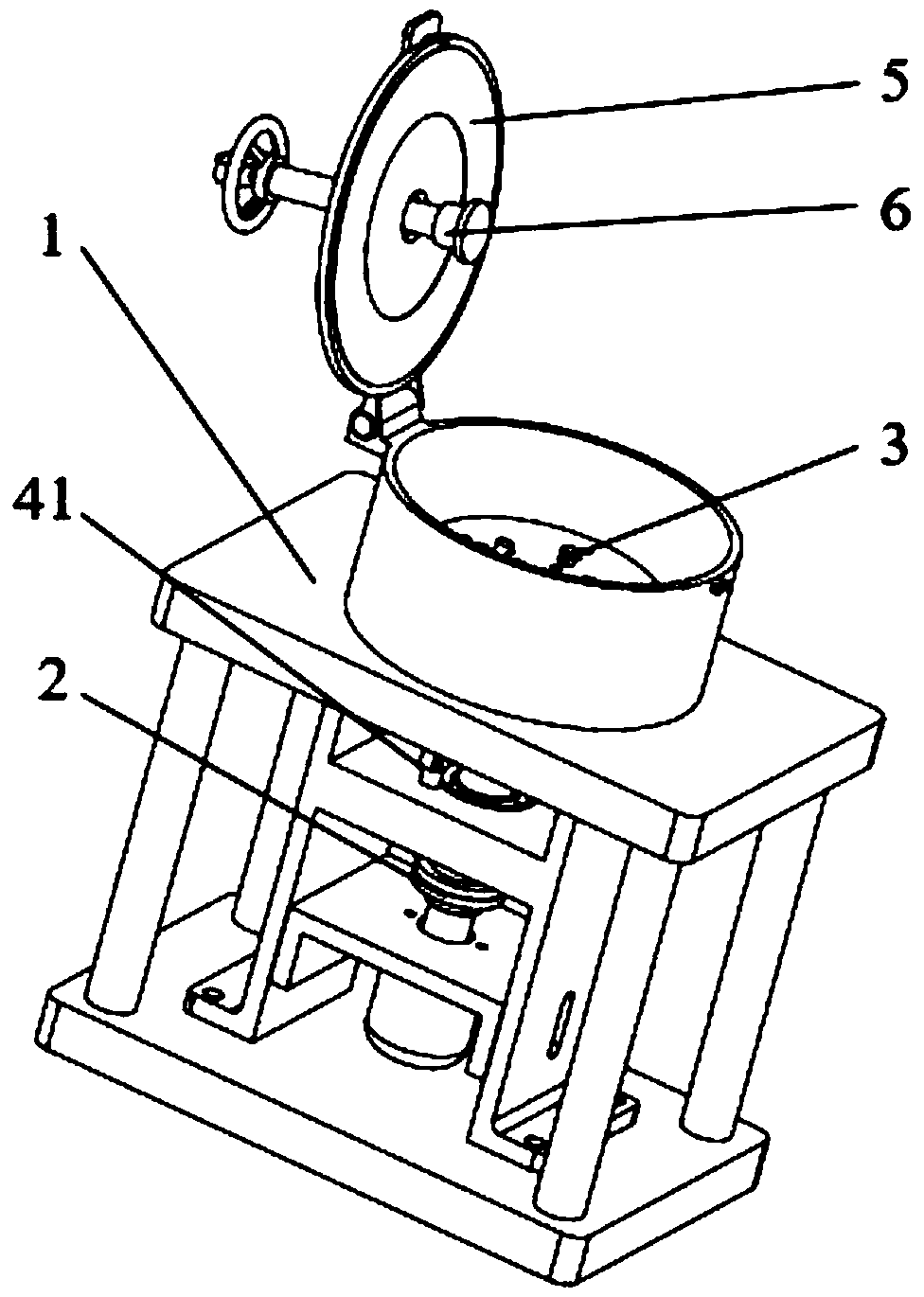

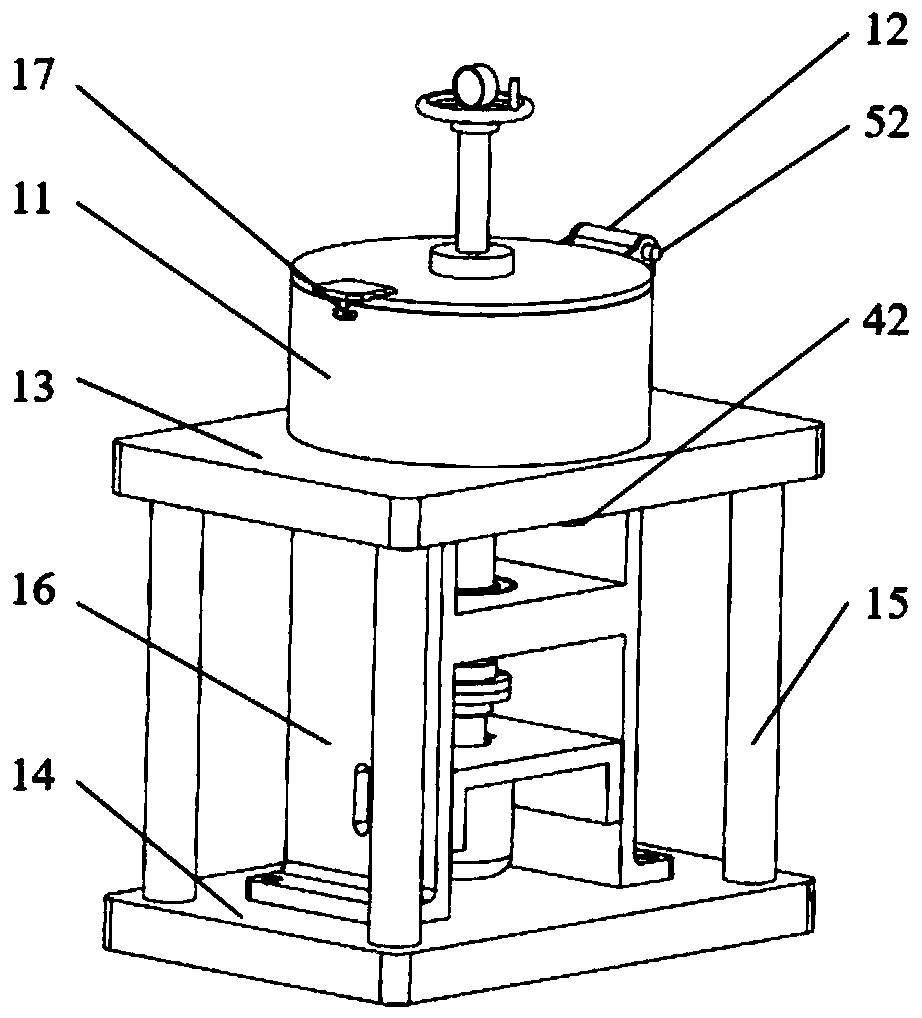

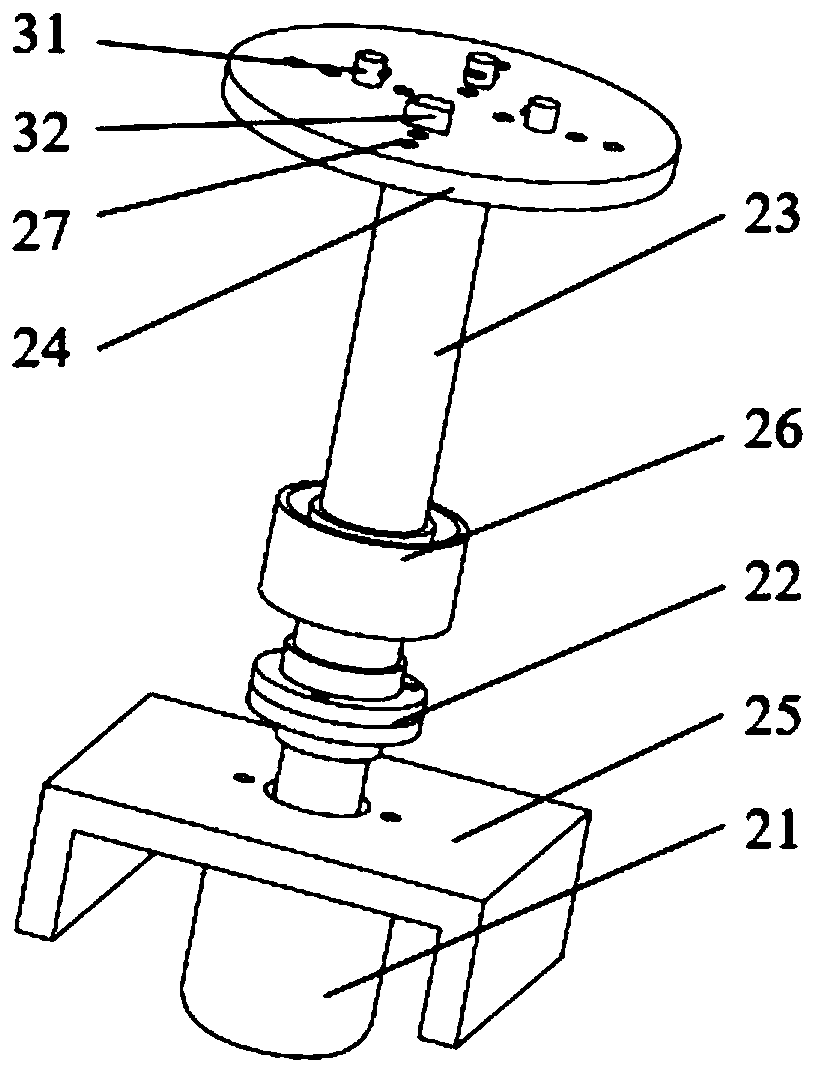

[0041] see figure 1 and Figure 5, a direct bonding device for hydrophilic wafers of the present invention, comprising: a frame 1, a turntable assembly 2, a block clamp assembly 3, a water supply and drainage system, an upper cover 5 and a pressure applying device 6.

[0042] Frame 1 consists of upper and lower parts, which are used for the support and protection of the device and the positioning and installation of related components; Cylindrical cylinder body 11, the rotary table 24 is arranged in the cylinder body 11, the block fixture assembly 3 is installed on the rotary table 24, the water supply and drainage system is installed on both sides of the rotary table 24, the upper cover 5 is connected with the The cylinders are connected, and the pressure applying device 6 is installed in the center of the upper cover 5 .

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com