Tunnel type microwave sterilization device and method for sterilizing starch type raw materials by microwave

A microwave sterilization and tunnel technology, applied in application, food science, food preservation, etc., can solve problems such as difficulty in completely killing Bacillus spores, impact on food quality, etc., and achieve reduced nutrient loss, good sterilization effect, and application prospects. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

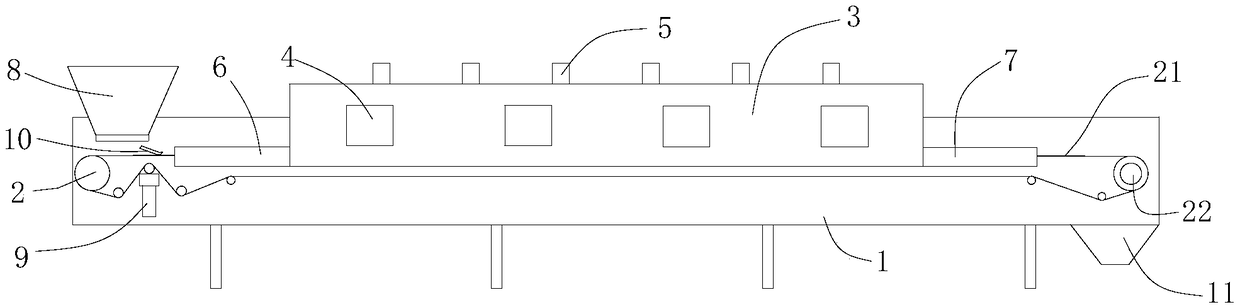

[0027] Such as figure 1 As shown, the tunnel-type microwave sterilization device of the present invention includes a support 1, on which a material delivery mechanism 2 and a microwave sterilization tunnel 3 are arranged, and the material delivery mechanism 2 includes a conveyor belt 21 and a belt power unit 22, and the conveyor belt 21 Through the microwave sterilization tunnel 3, the materials can be transferred to the microwave sterilization tunnel 2 for sterilization. The microwave sterilization tunnel 3 is provided with a visible door 4 and a microwave generator 5. The microwave frequency of the microwave generator is 2450 MHz. The visible door 4 is provided with an automatic power-off protection device for opening the door, which can monitor the inside of the microwave sterilization tunnel 3 at any time. The situation of the microwave sterilization tunnel 3 can also be inspected, and the microwave sterilization tunnel 3 can be overhauled. When the visible door 4 is opene...

Embodiment 2

[0033] Utilize the microwave to sterilize the barley powder, comprising the following steps:

[0034] a) Turn on the main power switch of the tunnel microwave sterilization device in Example 1, set the microwave power: 2000Kw; sterilization time: 120 seconds; transmission speed: 1m / min; feed height: 80mm; Turn on microwave sterilization;

[0035] b) Put the barley powder into the vibrating feeding hopper, drop it on the conveyor belt for conveying, scrape off the adjustable scraper and adjust the feeding height, pass through the microwave suppressor at the feeding port, and send it to the microwave sterilization tunnel for microwave Sterilization, after the sterilization is completed, it is sent through the microwave suppressor at the discharge port to the discharge hopper for discharge, realizing the continuous transmission and sterilization of the barley powder.

[0036] The use of microwaves to sterilize barley powder has high efficiency, short time, and uniform sterilizat...

Embodiment 3

[0038] Utilize microwave to sterilize red bean powder, comprise the following steps:

[0039] a) Turn on the main power switch of the tunnel microwave sterilization device in Example 1, set microwave power: 1000Kw; sterilization time: 240 seconds; transmission speed: 3m / min; feed height: 80mm; sterilization temperature: 70°C, Turn on microwave sterilization;

[0040] b) Put the red bean powder into the vibrating feeding hopper, drop it on the conveyor belt for transmission, scrape off the adjustable scraper and adjust the feeding height, pass through the microwave suppressor at the feeding port, and send it to the microwave sterilization tunnel for microwave Sterilization, after the sterilization is completed, it is sent through the microwave suppressor at the discharge port to the discharge hopper for discharge, realizing the continuous transmission and sterilization of red bean powder.

[0041] The use of microwaves to sterilize red bean powder has high efficiency, short ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com