Turmeric composition and preparation method thereof

A composition and technology of turmeric, applied in the direction of food science, food ingredients containing natural extracts, functions of food ingredients, etc., can solve the problems of low solubility, high equipment requirements, and restrictions on the practical application of curcumin, so as to reduce decomposition and stabilize sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

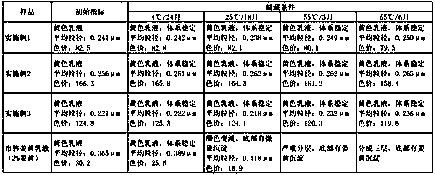

Embodiment 1

[0021] A turmeric composition consisting of:

[0022] Curcumin 10g, vitamin E (90% mixed tocopherols) 1g, soybean lecithin (phosphatidylcholine content 35wt%) 10g, caprylic glyceride 10g, tea saponin 200g, glycerin 150g, water 619g.

[0023] The preparation method of above turmeric composition is as follows:

[0024] (1) Preheat caprylic acid glyceride to 80°C, add soybean lecithin and vitamin E and stir to dissolve, then add curcumin, continue stirring to completely dissolve curcumin, and obtain a turmeric solution;

[0025] (2) Mix water, glycerin and tea saponin, heat to 60°C while stirring, continue stirring to make a uniform liquid, and obtain an aqueous phase solution;

[0026] (3) High-speed shearing of the aqueous phase solution, and slowly adding the turmeric solution into the aqueous phase solution under shearing conditions, and after the addition of the turmeric solution, maintain high-speed shearing until the particle size is less than 2 μm to obtain a pre-emulsio...

Embodiment 2

[0029] A turmeric composition consisting of:

[0030] Curcumin 50g, vitamin E (70% mixed tocopherols) 5g, soybean lecithin (phosphatidylcholine content 32wt%) 25g, glyceryl caprylate 200g, tea saponin 400g, sorbitol 300g, water 20g.

[0031] The preparation method of above turmeric composition is as follows:

[0032] (1) Preheat caprylic acid glyceride to 100°C, add soybean lecithin and vitamin E and stir to dissolve, then add curcumin, continue stirring to completely dissolve curcumin, and obtain a turmeric solution;

[0033] (2) Mix water, glycerin and tea saponin, heat to 60°C while stirring, continue stirring to make a uniform liquid, and obtain an aqueous phase solution;

[0034] (3) High-speed shearing of the aqueous phase solution, and slowly adding the turmeric solution into the aqueous phase solution under shearing conditions, and after the addition of the turmeric solution, maintain high-speed shearing until the particle size is less than 2 μm to obtain a pre-emulsi...

Embodiment 3

[0037] A turmeric composition consisting of:

[0038] Curcumin 30g, vitamin E (80% mixed tocopherols) 3g, soybean lecithin (phosphatidylcholine content 32wt%) 12g, caprylic acid glyceride 150g, tea saponin 300g, maltitol 200g, water 305g

[0039] The preparation method of above turmeric composition is as follows:

[0040] (1) Preheat caprylic acid glyceride to 90°C, add soybean lecithin and vitamin E and stir to dissolve, then add curcumin, continue stirring to completely dissolve curcumin, and obtain a turmeric solution;

[0041] (2) Mix water, glycerin and tea saponin, heat to 60°C while stirring, continue stirring to make a uniform liquid, and obtain an aqueous phase solution;

[0042] (3) High-speed shearing of the aqueous phase solution, and slowly adding the turmeric solution into the aqueous phase solution under shearing conditions, and after the addition of the turmeric solution, maintain high-speed shearing until the particle size is less than 2 μm to obtain a pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com