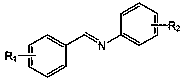

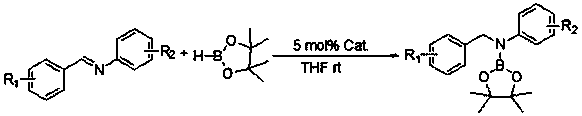

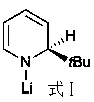

Application of n-Butyl Lithium in Catalytic Hydroboration of Imine and Borane

A technology of n-butyllithium and catalytic imine, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low yield of catalytic system and expensive catalyst , long reaction time and other problems, to achieve the effect of simple and controllable reaction, short reaction time and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: n-Butyl Lithium Catalyzed Hydroboration Reaction of Beniylidene Aniline and Pinacol Borane

[0023] In the reaction flask that has been dehydrated and deoxygenated, add 0.5 mmol of aniline under argon protection, add 100ul THF, then add 0.5 mmol (0.0726 mL) borane with a pipette and mix well, and finally add 25 ul of n-butyl Lithium tetrahydrofuran solution (1M) (5 mol% dosage, the same below), after reacting for 2 h, use a dropper to draw a drop into the NMR tube, add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 90%. NMR data of the product: 1 H NMR (CDCl 3 , 400 MHz) δ:7.29~7.12(m, 9H), 6.88~6.84 (t, 1H), 4.69 (s, 2H), 1.29 (s, 12H).

Embodiment 2

[0024] Embodiment 2: N-butyllithium catalyzes the hydroboration reaction of benzidine and pinacol borane

[0025] In the reaction flask that has been dehydrated and deoxygenated, add 0.5 mmol of benzylaniline under the protection of argon, add 100ul THF, then add 0.55 mmol (0.0798 mL) borane with a pipette and mix well, and finally add 25 ul of n-butyl Lithium tetrahydrofuran solution (1M) (5 mol% dosage, the same below), after reacting for 2 h, use a dropper to draw a drop into the NMR tube, add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 95%. NMR data of the product: 1 H NMR (CDCl 3 , 400 MHz) δ:7.29~7.12(m, 9H), 6.88~6.84 (t, 1H), 4.69 (s, 2H), 1.29 (s, 12H).

Embodiment 3

[0026] Embodiment three: n-butyllithium catalyzes the hydroboration reaction of benzidine and pinacol borane

[0027] In the reaction flask that has been dehydrated and deoxygenated, add 0.5 mmol of benzylaniline under argon protection, add 100ul THF, then add 0.6 mmol (0.0871 mL) borane with a pipette and mix well, and finally add 25 ul of n-butyl Lithium tetrahydrofuran solution (1M) (5 mol% dosage, the same below), after reacting for 1 h, use a dropper to draw a drop into the NMR tube, add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 96%. NMR data of the product: 1 H NMR (CDCl 3 , 400 MHz) δ :7.29~7.12(m, 9H), 6.88~6.84 (t, 1H), 4.69 (s, 2H), 1.29 (s, 12H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com