Automatic dome attaching machine and working method thereof

An automatic, top-machine technology, applied in the direction of mechanical equipment, conveyor objects, material gluing, etc., can solve the problems of tooling wear, reducing tooling service life, and difficulty in ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

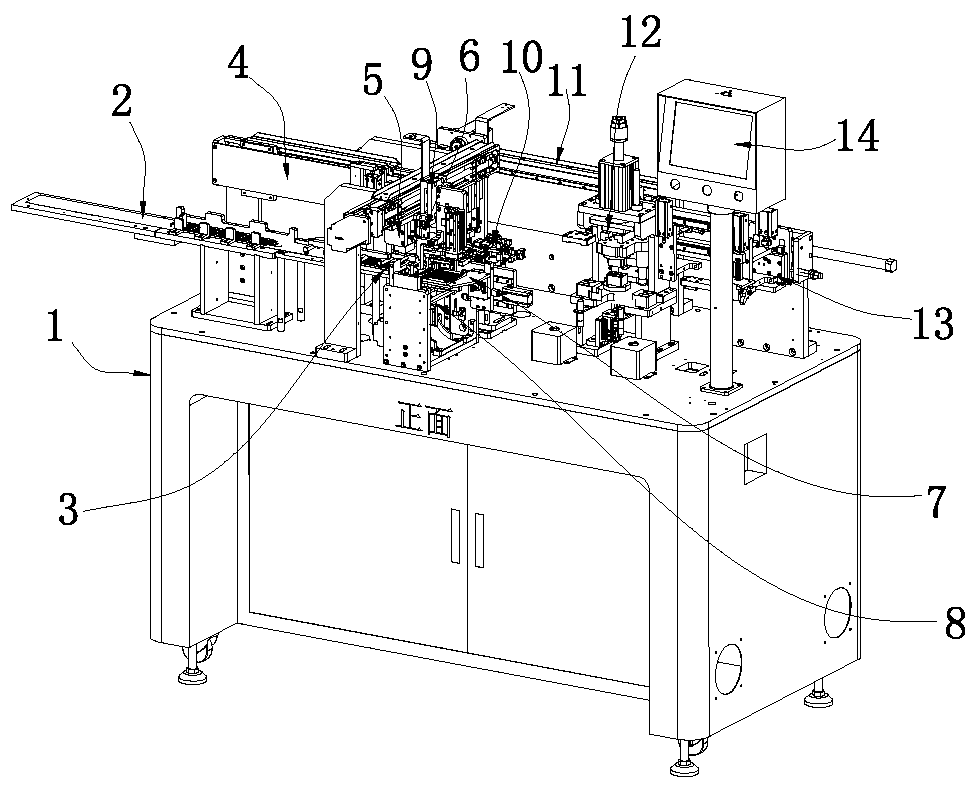

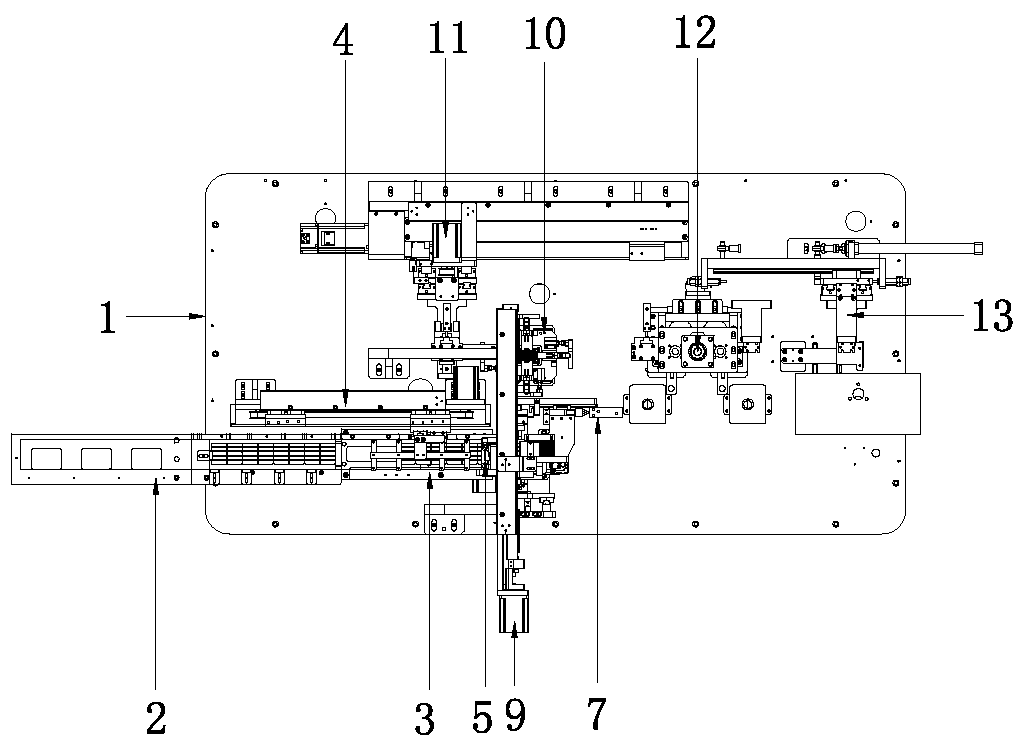

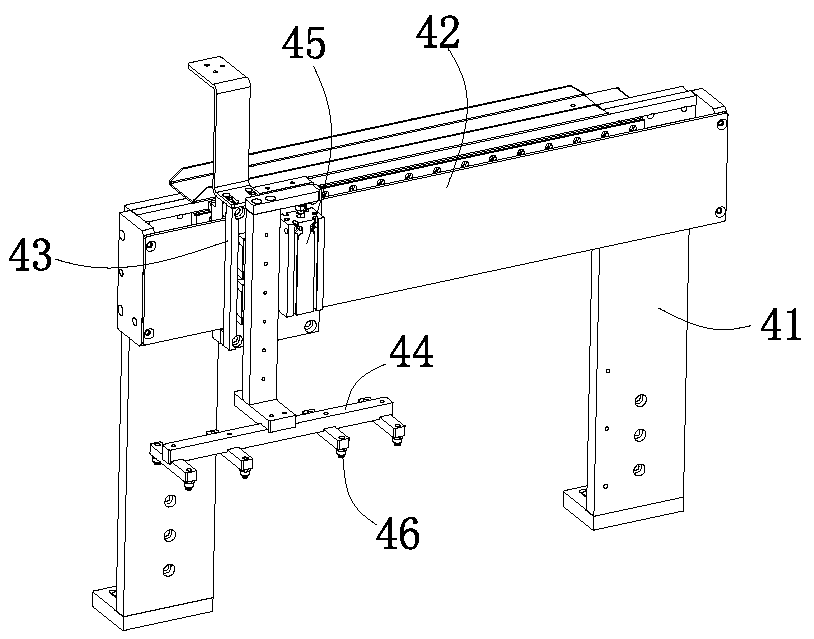

[0044] Examples, see Figure 1 to Figure 12 , an automatic ball topping machine provided in this embodiment, which includes a frame 1, a conveying track 2, a feeding table 3, a suction feeding mechanism 4, a belt pre-pressing mechanism 5, a belt bending mechanism 6, The tray moving mechanism 7, the clamping pull-down mechanism 8, the first suction and transfer mechanism 9, the alignment alignment mechanism 10, the second suction and transfer mechanism 11, the pressing mechanism 12 and the suction and blanking mechanism 13, this implementation Among the examples, for the convenience of operation, the automatic ball topping machine of the present invention also includes a PLC controller 14, which is arranged on the frame 1 through a pole, and is connected with the conveying track 2 and the suction feeding mechanism respectively. 4. Strip pre-pressing mechanism 5, strip bending mechanism 6, tray moving mechanism 7, clamping pull-down mechanism 8, first suction transfer mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com