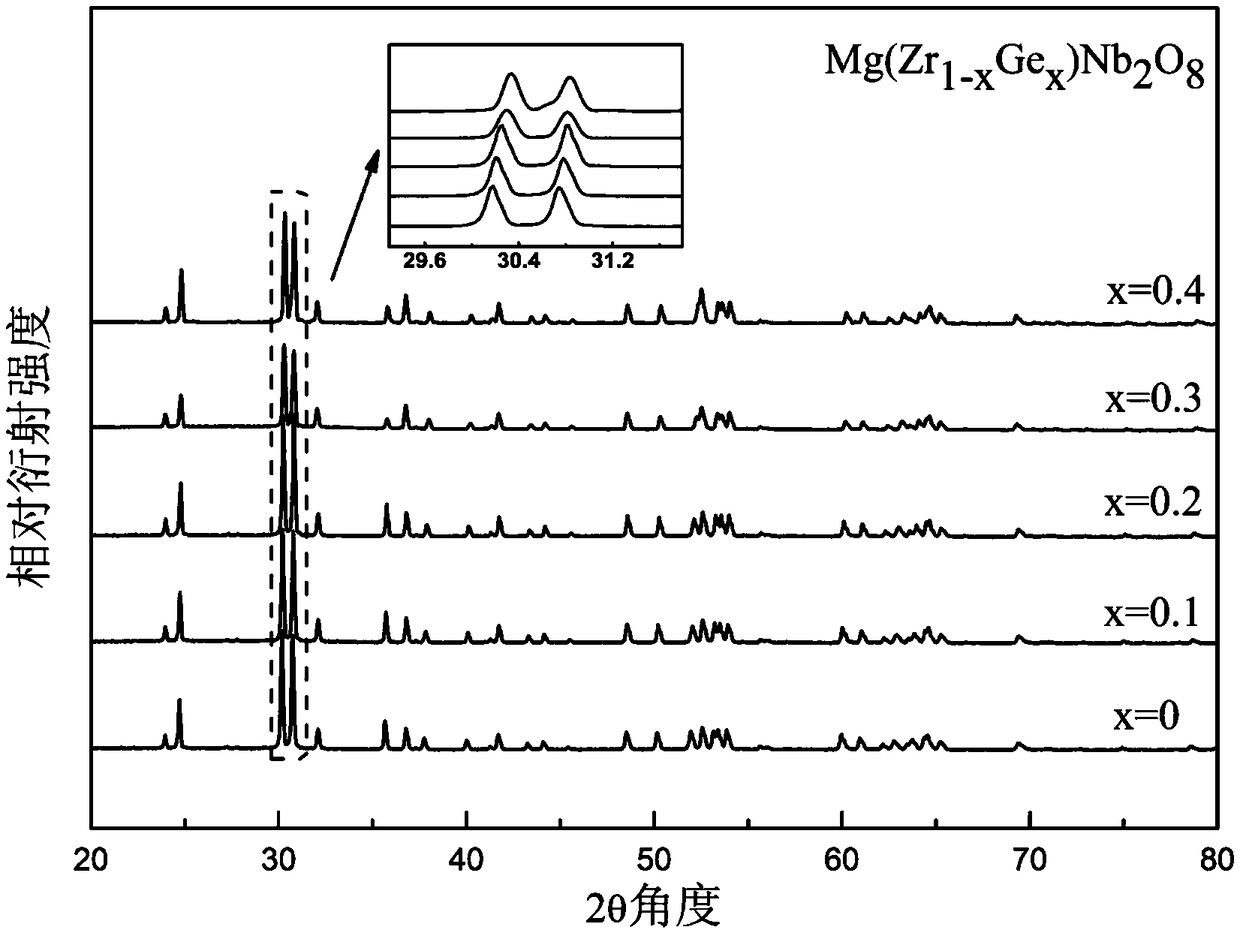

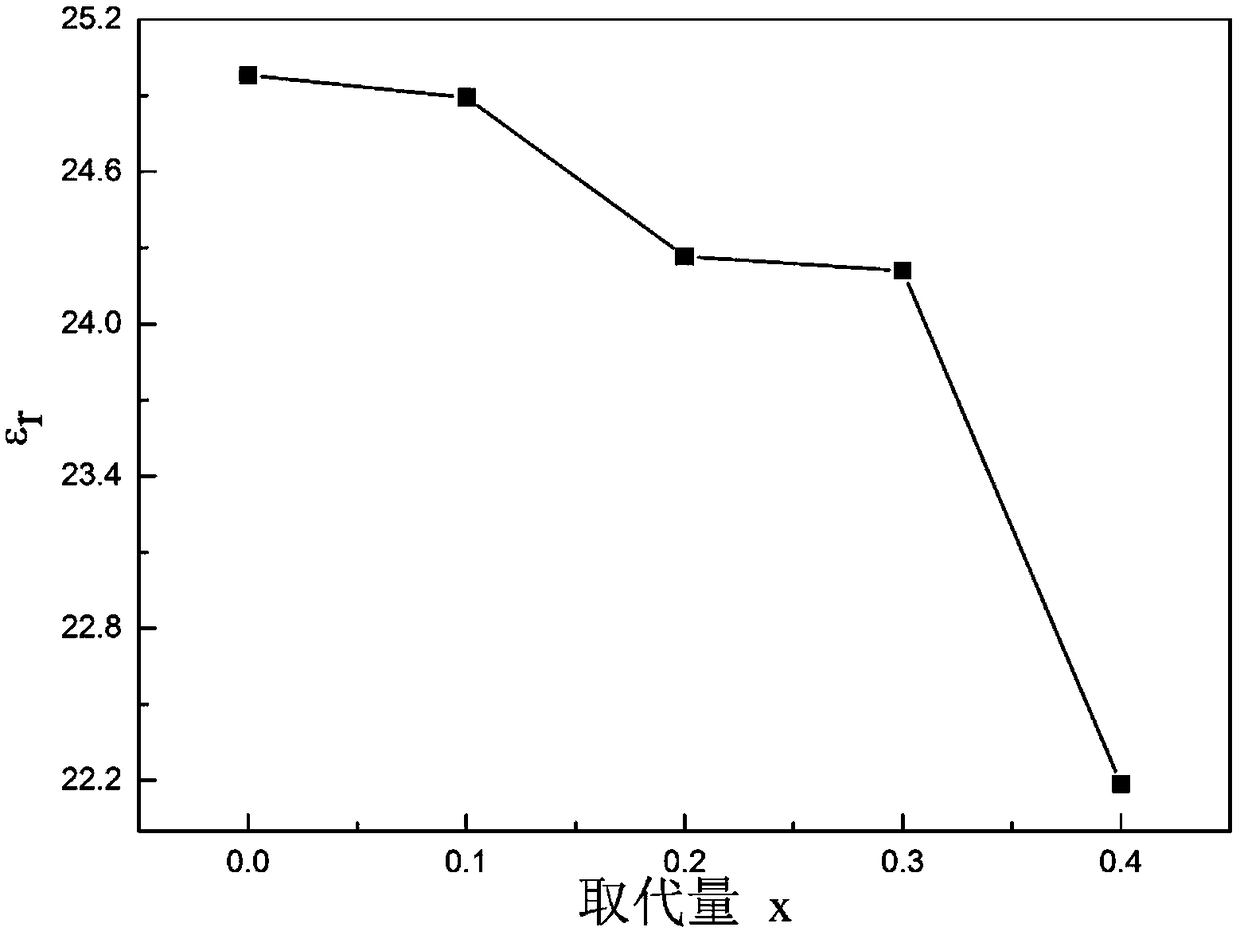

Magnesium-zircon-germanium-niobium microwave dielectric ceramic with low dielectric constant and ultra-low dielectric loss and preparation method and application

A technology of microwave dielectric ceramics and low dielectric constant, which is applied in the field of ceramic compositions, can solve the problems of large dielectric constant and lack of ultra-low dielectric loss material system, and achieve the improvement of dielectric constant, no pollution in the process, and the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]A method for preparing magnesium-zirconium-germanium-niobium series microwave dielectric ceramics with low dielectric constant and ultra-low dielectric loss, specifically comprising the following steps:

[0034] (1) According to the microwave dielectric ceramic composition Mg (Zr 1-x Ge x )Nb 2 o 8 (x=0.1), said MgO-1.8855g, ZrO 2 -5.1886g, GeO2-0.4895g, Nb 2 o 5 -12.4364g of ingredients, 20g in total; the mixed powder is added to the ball mill tank, after adding 160ml of deionized water and 150g of zirconium balls, ball mill on a planetary ball mill for 6 hours, and the speed of the ball mill is 1000 rpm;

[0035] (2) Place the raw material after ball milling under the temperature condition of 110° C. to dry, and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0036] (3) Calcining the powder with uniform particles at 1100°C for 3 hours;

[0037] (4) Put the calcined powder into a ball mill jar, add deionized water and zirconia balls, mil...

Embodiment 2

[0040] A method for preparing magnesium-zirconium-germanium-niobium-based microwave dielectric ceramics with low dielectric constant and ultra-low dielectric loss, the basic steps of which are basically the same as in Example 1, except that in step (1) according to the composition of microwave dielectric ceramics Mg(Zr 1-x Ge x )Nb 2 o 8 (x=0.2), said MgO-1.8937g, ZrO 2 -4.6322g, GeO2-0.9833g, Nb 2 o 5 -12.4907g batching, totally 20g, afterward step is identical with embodiment 1.

Embodiment 3

[0042] A method for preparing magnesium-zirconium-germanium-niobium-based microwave dielectric ceramics with low dielectric constant and ultra-low dielectric loss, the basic steps of which are basically the same as in Example 1, except that in step (1) according to the composition of microwave dielectric ceramics Mg(Zr 1-x Ge x )Nb 2 o 8 (x=0.3), said MgO-1.9021g, ZrO 2 -4.0710g, GeO2-1.4815g, Nb 2 o 5 -12.5455g batching, totally 20g, afterward step is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com