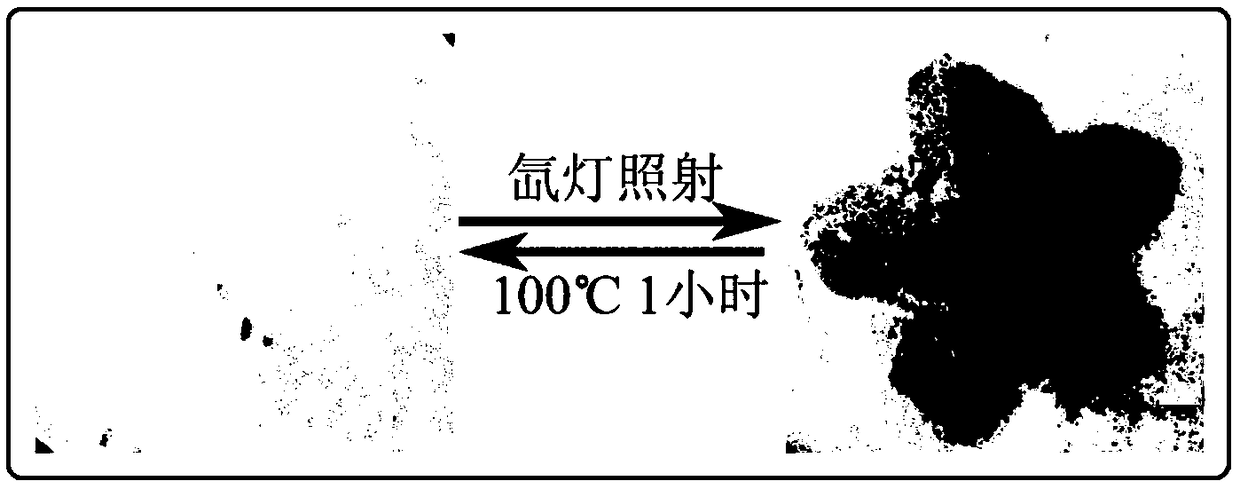

Electron transfer type hybrid photochromic material and preparation method thereof

A photochromic material and electron transfer technology, applied in the direction of color-changing fluorescent materials, organic chemical methods, chemical instruments and methods, etc., to achieve the effects of convenient operation, novel structure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

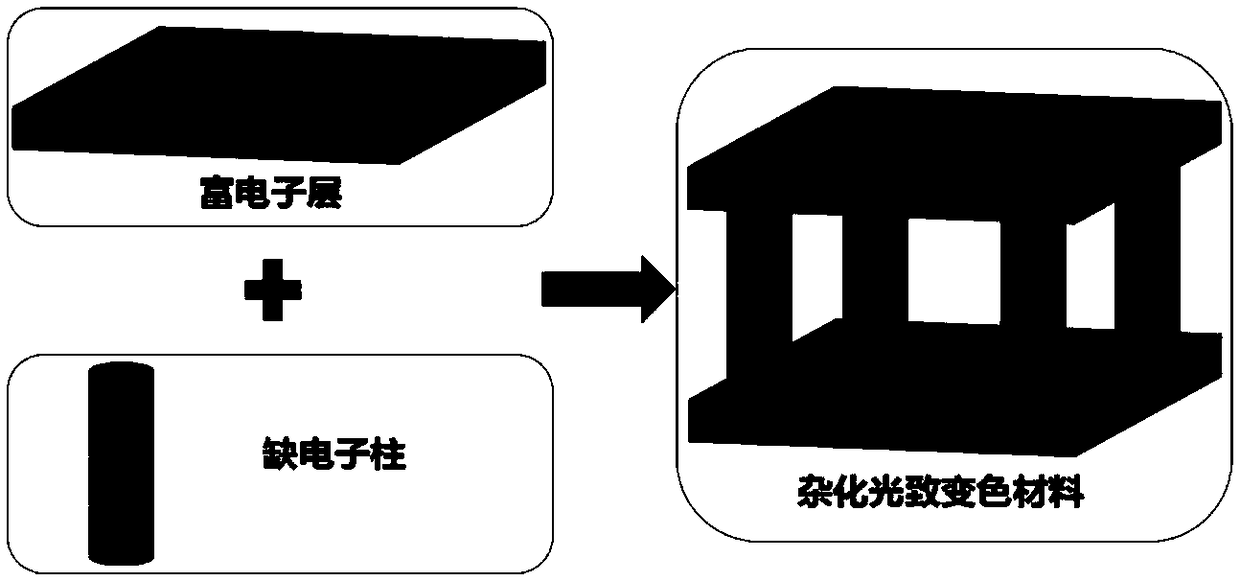

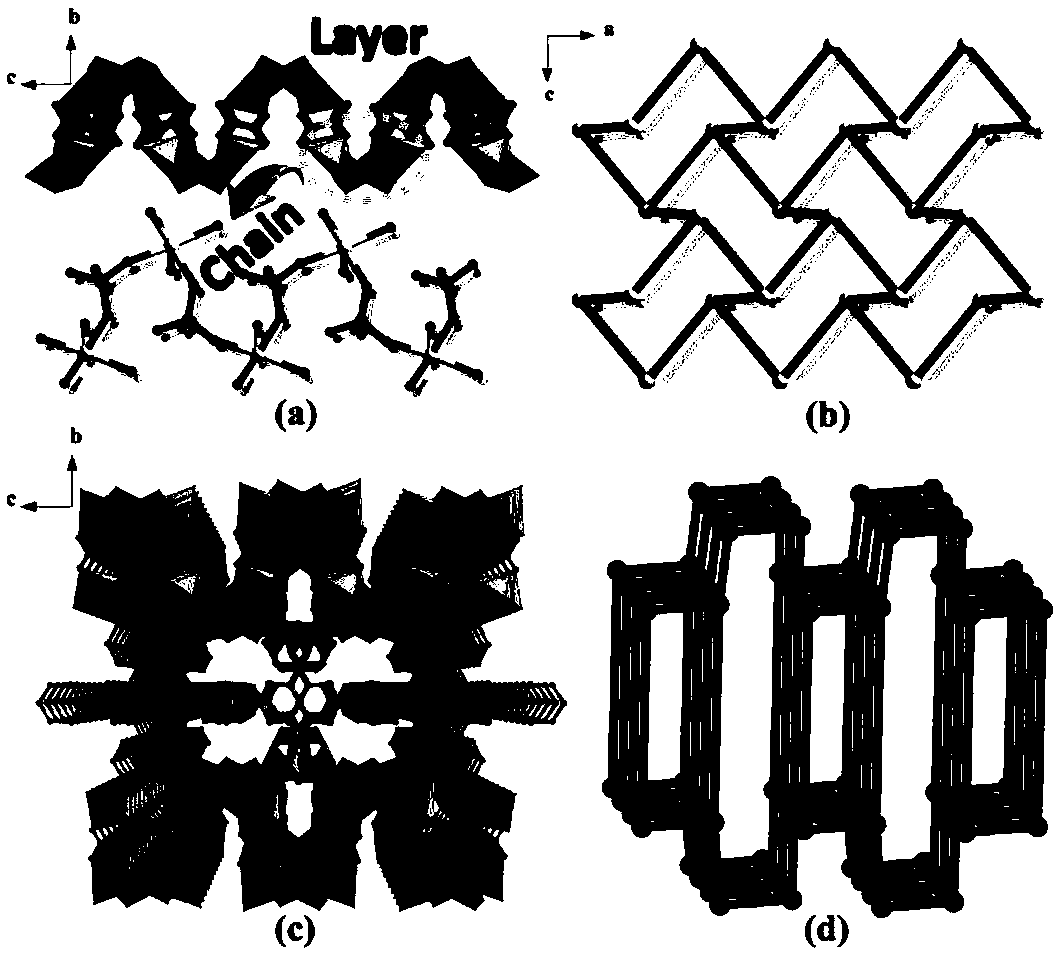

[0027] In this example, oxalic acid (3.1mmol, 0.39g), zinc oxide (2mmol, 0.16g), TPT (0.12mmol, 0.036g), phosphoric acid (0.2mL) and DMF (0.12mL) were sequentially added to polytetrafluoroethylene as a lining Sealed in a stainless steel reaction kettle, and crystallized in an oven at 145°C for 7 days. After the reaction was completed, the stainless steel reaction kettle was taken out and cooled naturally at room temperature, and the crystals generated in the stainless steel reaction kettle were removed and washed repeatedly with deionized water for 5 times. , dried at room temperature to obtain colorless (or light purple) massive crystals, the prepared crystals were subjected to single crystal diffraction, and the data analysis showed that the obtained compounds had a columnar structure, in which phosphoric acid and oxalic acid chelated-bridged Zn 2+ A two-dimensional hybrid layer is formed, and the TPT ligand passes through the interlayer Zn 2+ Coordinated, pillared 2D layer ...

Embodiment 2

[0029] In this example, oxalic acid (3.1mmol, 0.39g), zinc oxide (2mmol, 0.16g), TPT (0.12mmol, 0.036g), phosphoric acid (0.2mL) and DMAc (0.12mL) were sequentially added to polytetrafluoroethylene as a lining Sealed in a stainless steel reaction kettle, crystallized in an oven at 145° C. for 7 days and after the reaction was completed, passed through the cooling, washing and drying methods as in Example 1. The characteristics and results of the target product obtained were the same as in Example 1.

Embodiment 3

[0031] In this example, oxalic acid (3.1mmol, 0.39g), zinc oxide (2mmol, 0.16g), TPT (0.12mmol, 0.036g), phosphoric acid (0.2mL) and DMAc (0.12mL) were sequentially added to polytetrafluoroethylene as a lining Sealed in a stainless steel reaction kettle, and crystallized in an oven at 145°C for 8 days. After the reaction was completed, through the cooling, washing and drying methods as in Example 1, the characterization and results of the target product obtained were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com