Laundry detergent and preparation method thereof

A technology for laundry detergent and raw materials, applied in the field of daily chemical products, can solve the problems of pollution, low foam, strong detergency, etc., and achieve the effects of good compatibility, more foam and strong detergency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

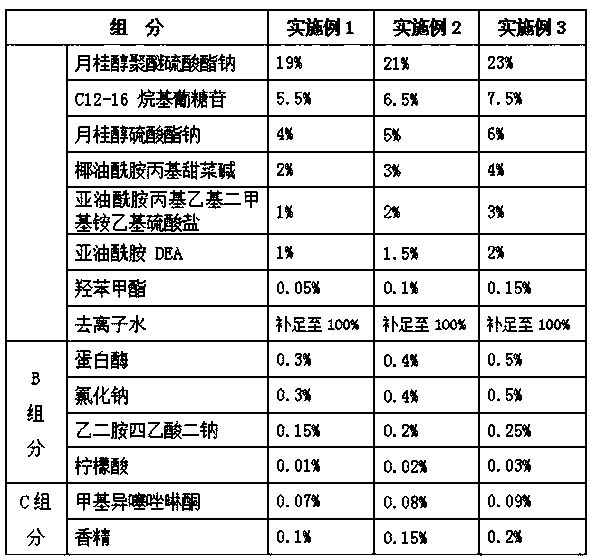

Embodiment 1-3

[0037] The preparation method of embodiment 1-3 is:

[0038] S1. Add the material of component A into the stirring pot, stir while heating, heat to 70°C-95°C, preferably 80°C-85°C, keep the temperature for 15-25 minutes, and stir evenly;

[0039] S2. Lower the temperature to 49-53°C, preferably to 50°C, then add the raw materials of component B into the stirring pot, stir for 7-15 minutes, and stir evenly;

[0040] S3. Continue to lower the temperature to 43-46°C, preferably to 45°C, then add the C component raw materials, stir for 7-15 minutes, and stir evenly;

[0041] S4, then add D component raw materials, adjust the pH value to 5.0-6.5;

[0042] S5. After passing the inspection, it is filled and packaged, and the finished product is put into storage.

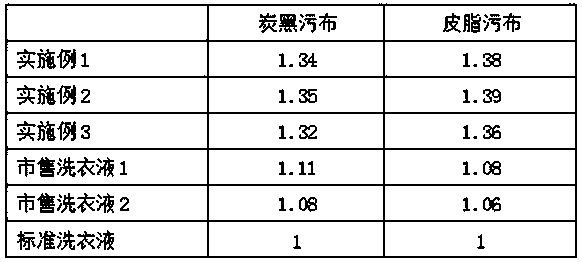

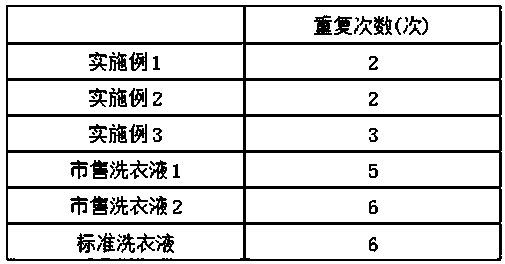

[0043] (2) Detergency test experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com