Preparation method of graphene-reinforced cobalt-based high-temperature alloy composite

A high-temperature alloy and composite material technology, which is applied in the field of composite materials, can solve the problem that graphene is not easy to disperse, and achieve excellent high-temperature mechanical properties, good reinforcement effect, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

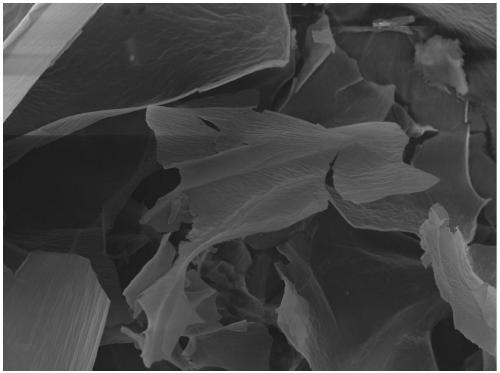

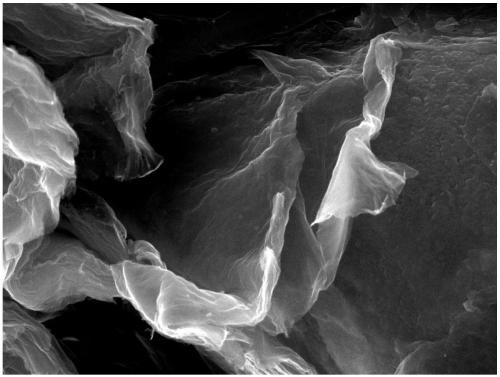

Image

Examples

preparation example Construction

[0051] A preparation method of a graphene-reinforced cobalt-based superalloy composite material, comprising the following steps:

[0052] S1 prepares cobalt-based superalloy powder and graphene.

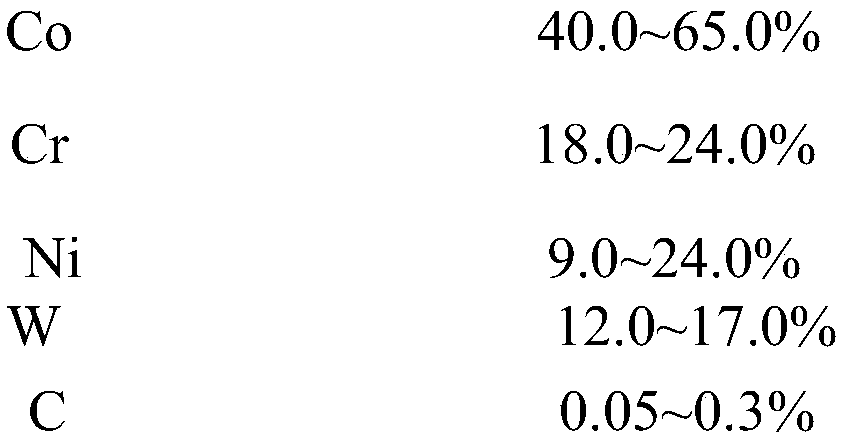

[0053] Preferably, the cobalt-based superalloy powder prepared in S1 contains the following components in parts by weight: the content of Co is 40.0-65.0%, the content of Cr is 18.0-24.0%, the content of Ni is 9.0-24.0%, The content of W is 12.0-17.0%, the content of C is 0.05-0.3%, the content of Si is ≤0.5%, the content of P is ≤0.05%, and the content of S is ≤0.05%. Under this condition, the comprehensive consideration of the comprehensive influence of each element in the cobalt-based superalloy on the cost and performance of the cobalt-based superalloy is conducive to the preferred orientation of graphene, which makes graphene produce better reinforcement of the cobalt-based superalloy Effect.

[0054] Wherein, the prepared cobalt-based superalloy powder is cobalt-based superal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com