Air conditioner system for compressor shell winding refrigerating agent copper pipe

A technology for air conditioning systems and compressors, which is applied in air conditioning systems, mechanical equipment, machines/engines, etc., and can solve the problems of frosting, shutdown, and low cooling efficiency of outdoor heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A detailed description will be given below in conjunction with the drawings and embodiments of the description.

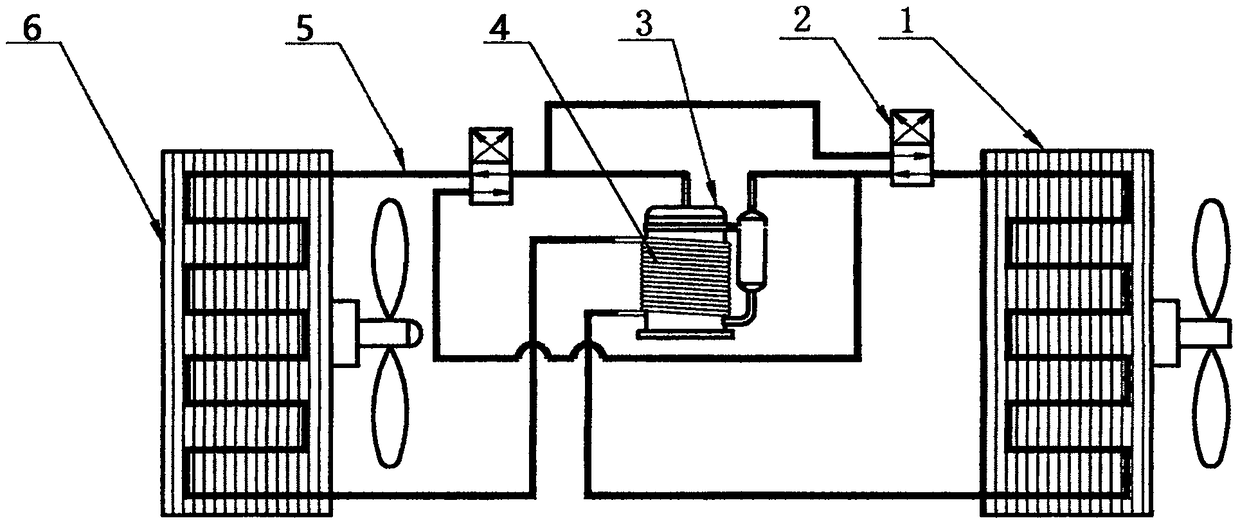

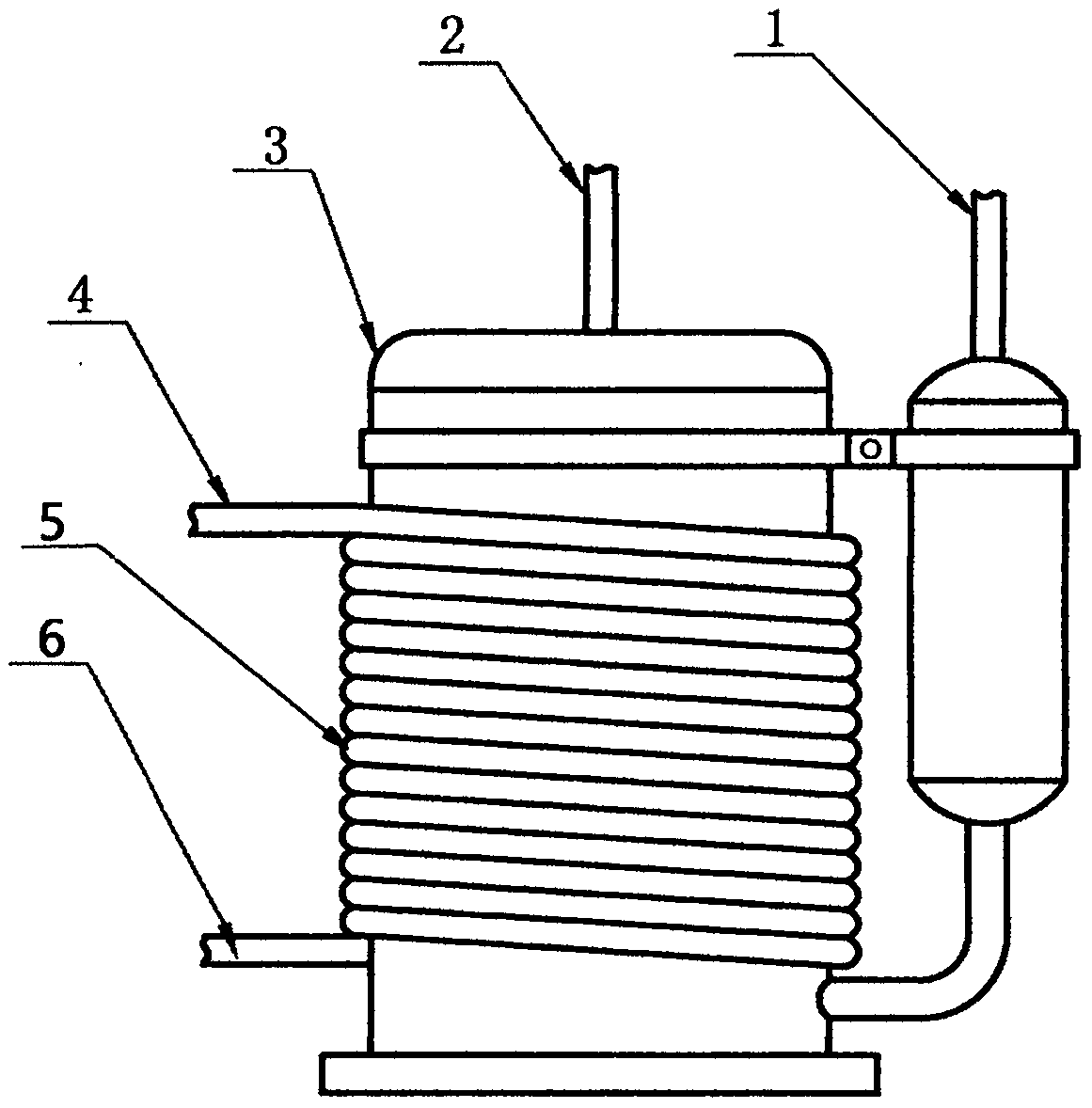

[0010] refer to figure 1 , when performing heating operation, the low-temperature and low-pressure refrigerant vapor from the outdoor unit heat exchanger (1) is sucked into the compressor, compressed into high-temperature and high-pressure gas, and then discharged into the indoor unit heat exchanger (5), and passed through the centrifugal fan The effect of heat exchange with indoor air is to dissipate heat and become a refrigerant liquid, and then pass through the spiral refrigerant copper tube (4) on the shell of the compressor (3) after capillary throttling, pressure reduction, and cooling, and then feed the compressor (3) After cooling down and absorbing heat, it enters the heat exchanger (1) of the outdoor unit, and under the action of the axial flow fan of the outdoor unit, it exchanges heat with the outdoor air and absorbs heat to become a low-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com