Solar energy measuring liquid heat conductivity coefficient experimental instrument and measurement method thereof

A technology of thermal conductivity and solar energy, applied in the direction of instruments, material thermal development, teaching models, etc., can solve problems such as inconvenient operation, unsmooth experiment, uneasy disassembly and assembly of equipment, etc., to improve experimental accuracy and experimental efficiency, avoid The effect of slow teaching progress and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

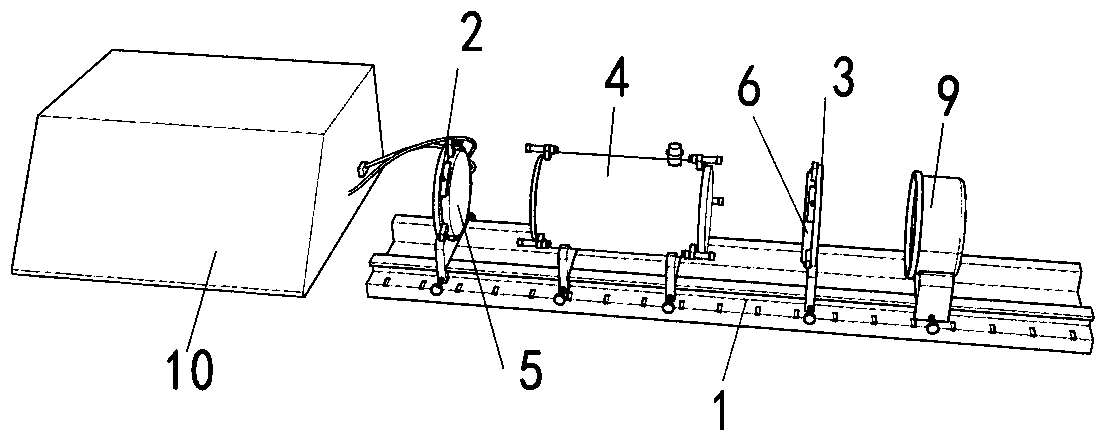

[0072] Specific embodiment: the specific steps of liquid thermal conductivity measuring method are as follows:

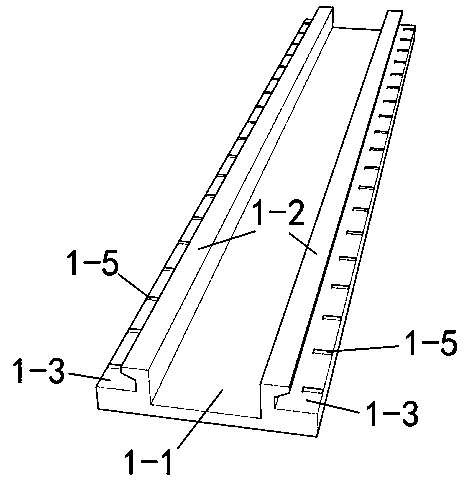

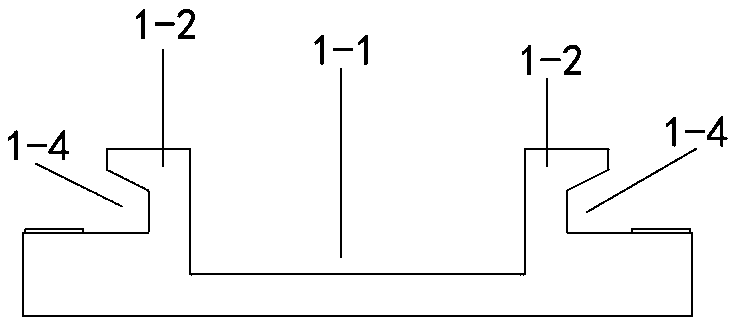

[0073] (1) Insert the heating plate rack 2, the sliding seat 2-1 for placing the liquid sample holding tank, the cooling plate frame 3, and the cooling fan 6 on the slide rail 1 in sequence from left to right; The fastening bolts 2-5 of the sliding seat are screwed inward to fix with the slide rail 1; the heating plate 5 is installed in the disc installation cavity 2-11 on the heating plate frame 2, and the fastening bolts 2-6 are passed through the disc Screw inward to fix;

[0074] (2) Unscrew the cup cover 4-1 of the liquid sample holding tank 4, fill it with the liquid to be tested, place it horizontally on the slide seat 2-1, and place the liquid filling port 4-3 vertically upward toward the heating tray 2 Push on one side to make the cup cover surface align with the right side of the heating plate 5;

[0075](3) Install the heat dissipation plate 6, push the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com