A kind of pcb preparation method and pcb thereof

A core board and board material technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, simultaneous processing of multiple printed circuits, etc., can solve problems such as insufficient reliability of PCB, uneven pattern distribution, inconsistent shrinkage, etc., to improve the degree of curing and polymer cross-linking firmness, good curing effect, uniform heating and sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

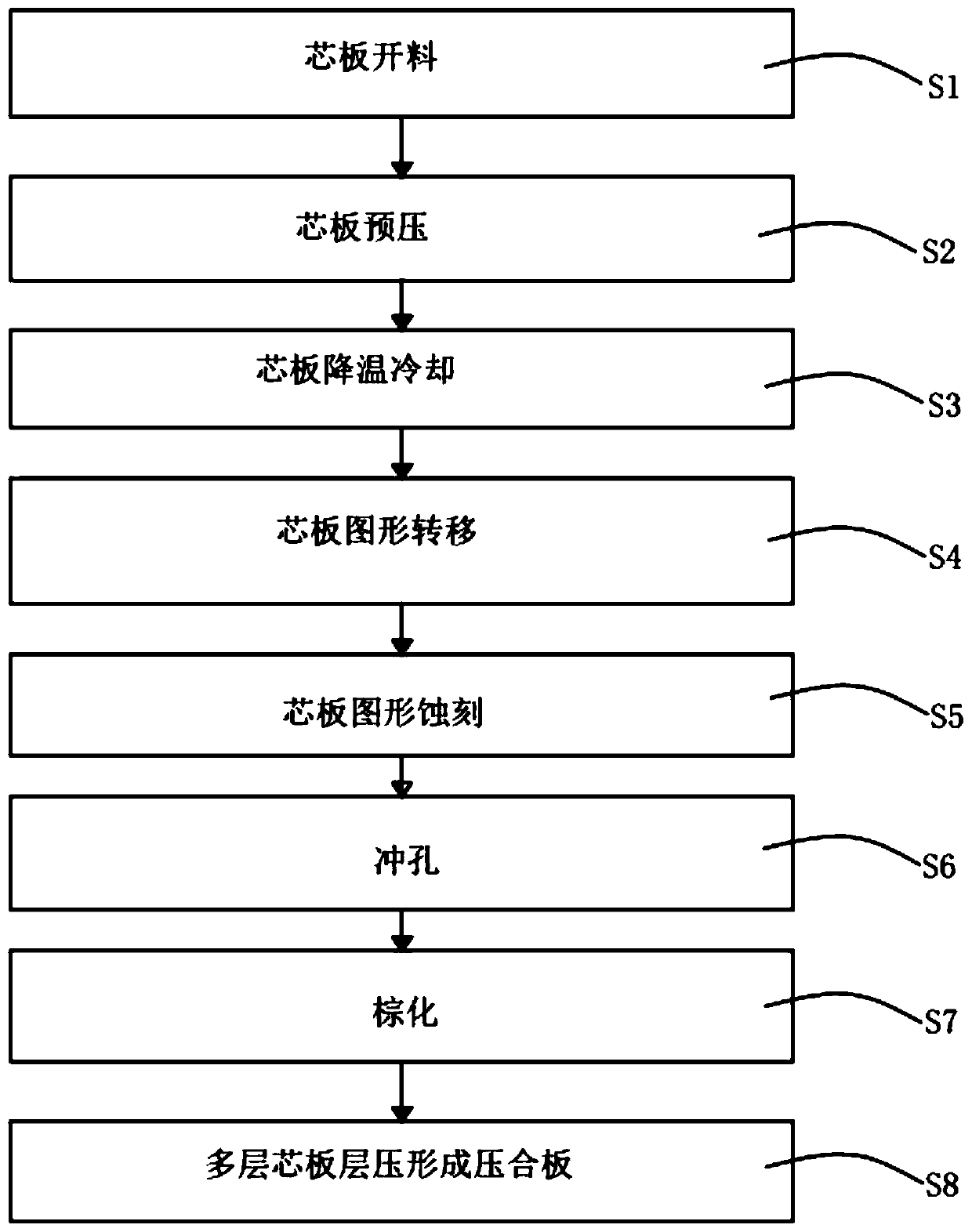

[0022] Such as figure 1 Shown, PCB preparation method of the present invention comprises the following steps:

[0023] S1: Core board cutting.

[0024] S2: Core plate pre-pressing; among them, the pre-pressing conditions are: the actual temperature of the plate is 5-10°C above the Tg point of the plate, the heating rate of the core plate is 2-4°C / min, the time is 60-90min, and the vacuum pressure is 350 ~450psi.

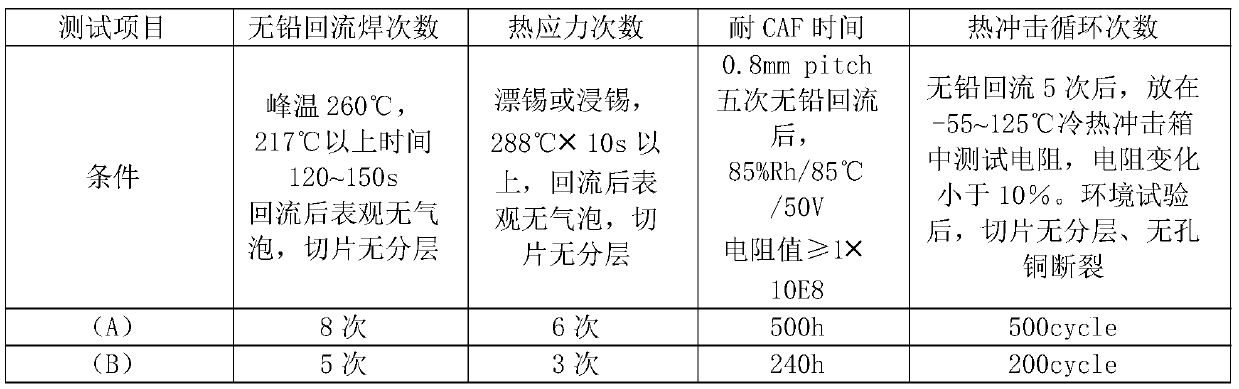

[0025] Taking a 28-layer board, 3.6mm thickness, 0.8mm pitch matrix 40╳40 BGA, and a PCB processed with a high Tg copper clad laminate as an example, the PCB (A) preloaded under the above preloading conditions is different from that under the non-th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com