Manufacturing process of disc brake upper pump

A production process and technology of disc brakes, applied in the field of production process of pumps on disc brakes, can solve the problems of labor costs, high plant costs, many operators, high R&D costs, etc., and achieve simple and efficient processing, high product qualification rate, and improved The effect of artificial potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

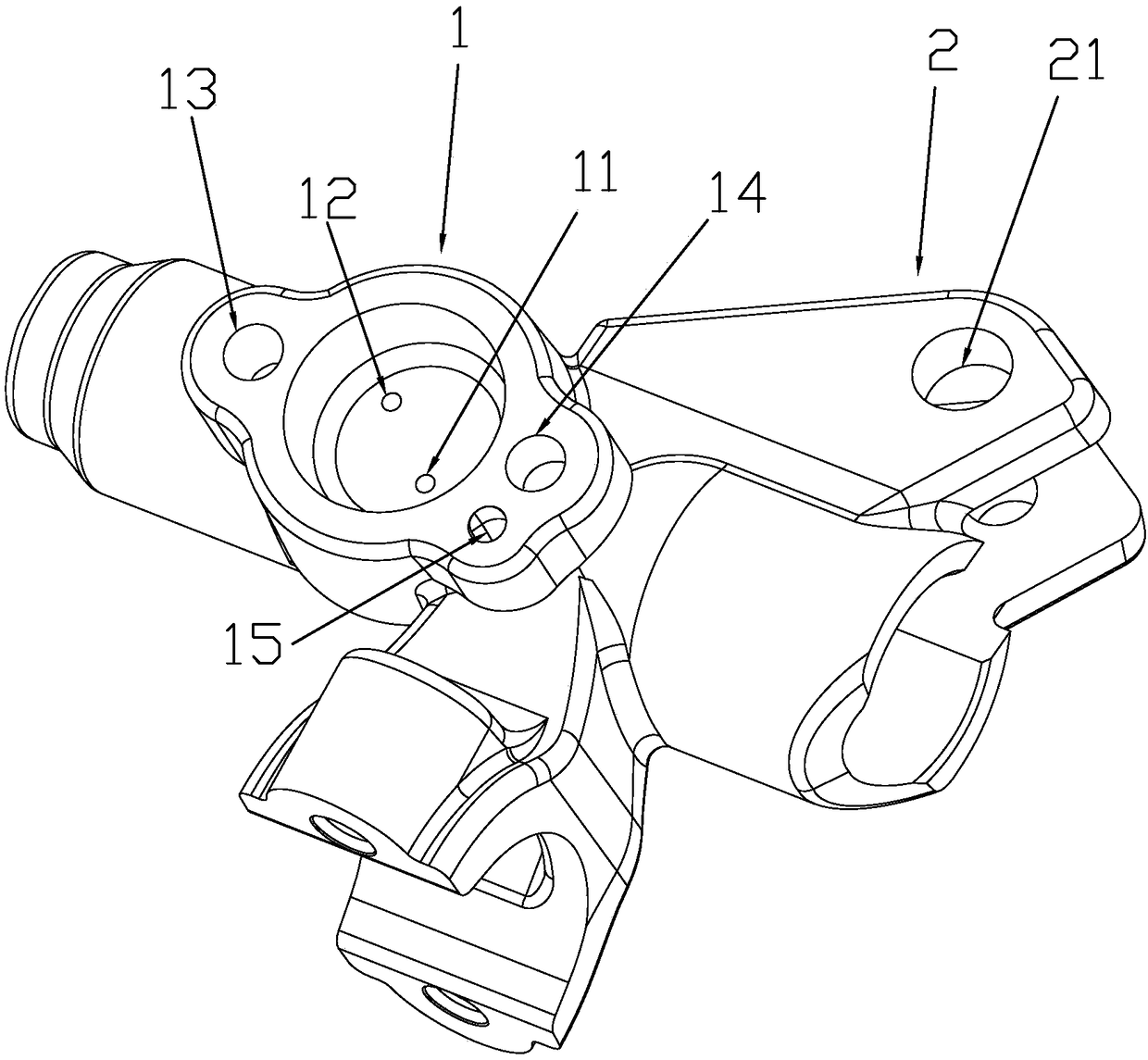

[0021] See figure 1 Shown: A manufacturing process of a disc brake upper pump, which is characterized by including the following steps:

[0022] Step 1: Die-casting the raw materials into a disc brake upper pump blank part, the upper pump blank part includes an oil cup connecting end 1 for connecting an oil cup 1 and a handle connecting end 2 for connecting a brake handle;

[0023] Step 2: Cut off the leftover material of the pump blank on the disc brake and remove the burrs;

[0024] Step 3: Put the rough parts of the disc brake on the pump for sand throwing;

[0025] Step 4: Perform mechanical processing on the upper pump rough parts of the disc brake after sanding, and the mechanical processing includes the following steps:

[0026] a) Use CNC machine tools to drill the plunger hole;

[0027] b) Using the plunger hole as the positioning hole, use the first drilling rig to drill the oil supply hole 11 and the oil return hole 12 in the oil cup connecting end 1;

[0028] c) Use the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com