Landing method of submarine pipeline in offshore petroleum engineering construction process

A technology for submarine pipelines and offshore oil, which is applied to drilling equipment and methods, earthwork drilling, underwater drilling, etc. It can solve the problems of long construction period, large investment in construction resources, and large engineering workload, so as to reduce construction operations The effect of reducing the quantity, reducing the construction cost and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

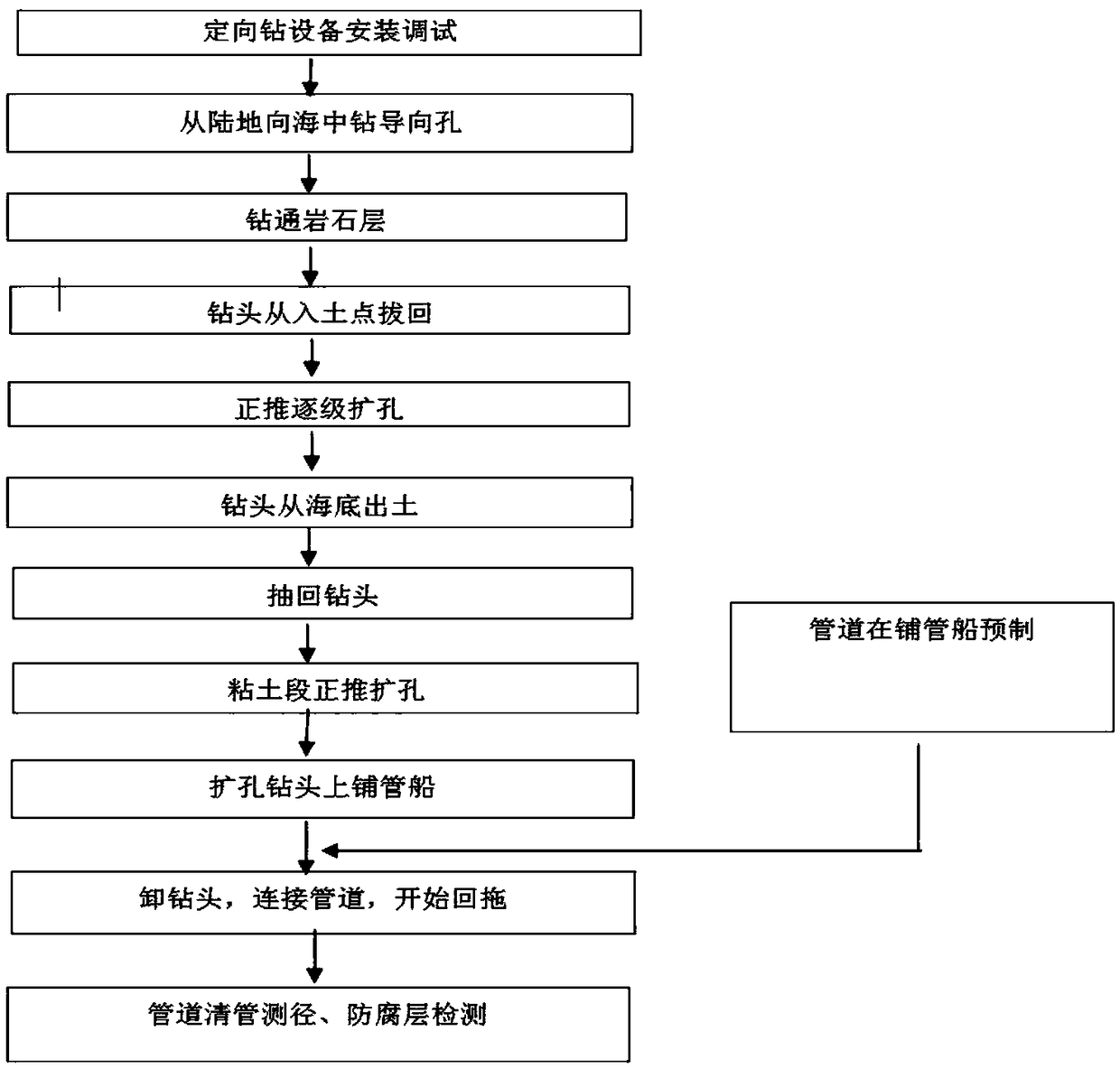

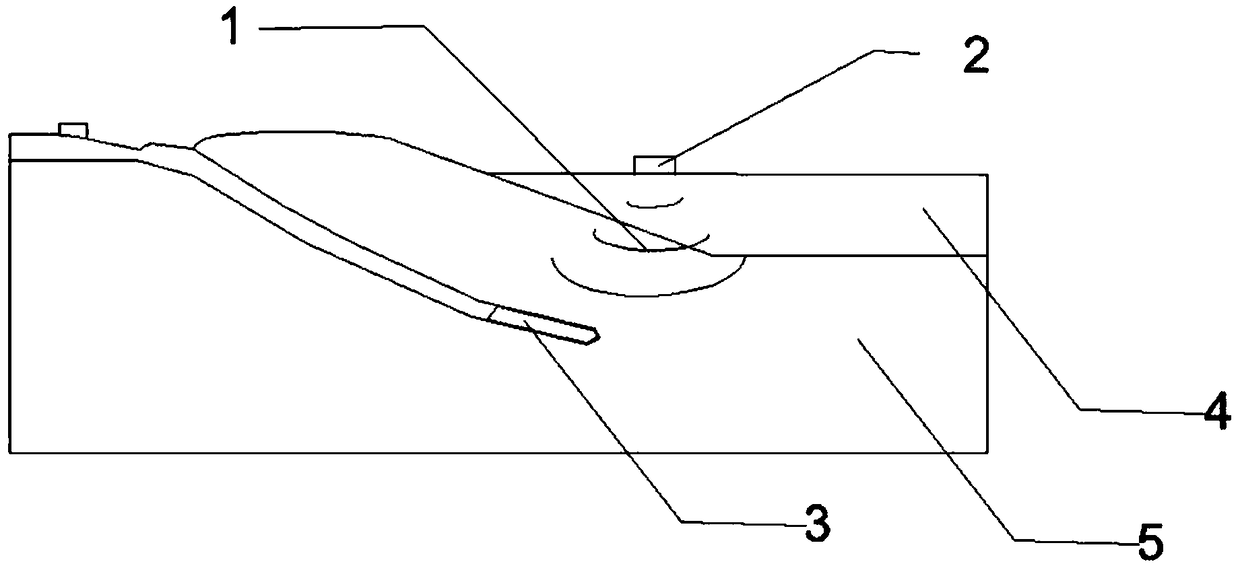

[0028] refer to figure 1 , using directional drilling from the land to the sea, after passing through the seabed rock layer and overburden, the pipeline is dragged back in the drill hole to realize the landing of the submarine pipeline from the sea to the land; the construction process is: installation and commissioning of directional drilling equipment → from the land Drill the pilot hole into the sea → drill through the rock layer → pull the drill bit back from the land entry point → adopt the forward push method to ream step by step → the drill bit is unearthed from the seabed → withdraw the drill bit → adopt the forward push method for the overburden (clay layer and silt layer) Reaming → reaming drill bit connected to the pipe-laying ship → unloading the drill bit, connecting the pipe → prefabricating the pipe on the pipe-laying ship, starting back towing → testing after the back towing is completed.

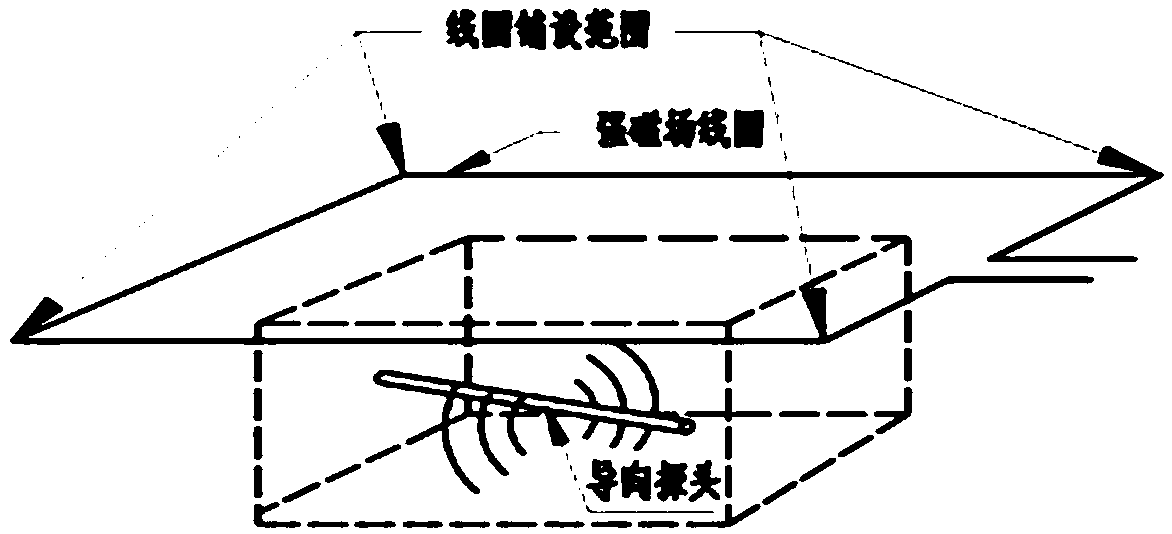

[0029] 1. Guide hole precision control - magnetic target positioning co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com