Drying device for food detection

A drying device and food testing technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of lowering user work efficiency, inability to save energy, and environmental pollution, so as to save energy and reduce labor costs , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

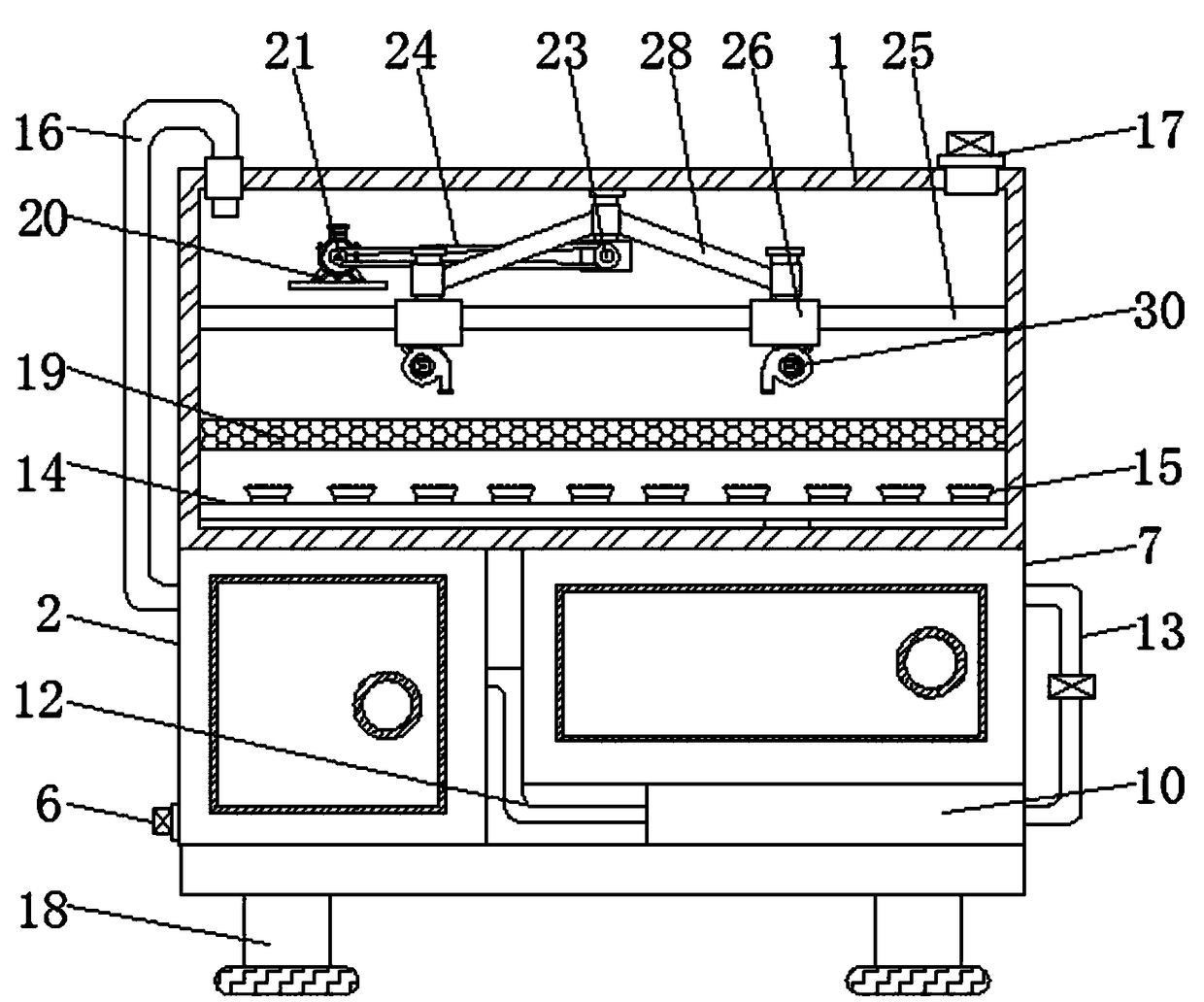

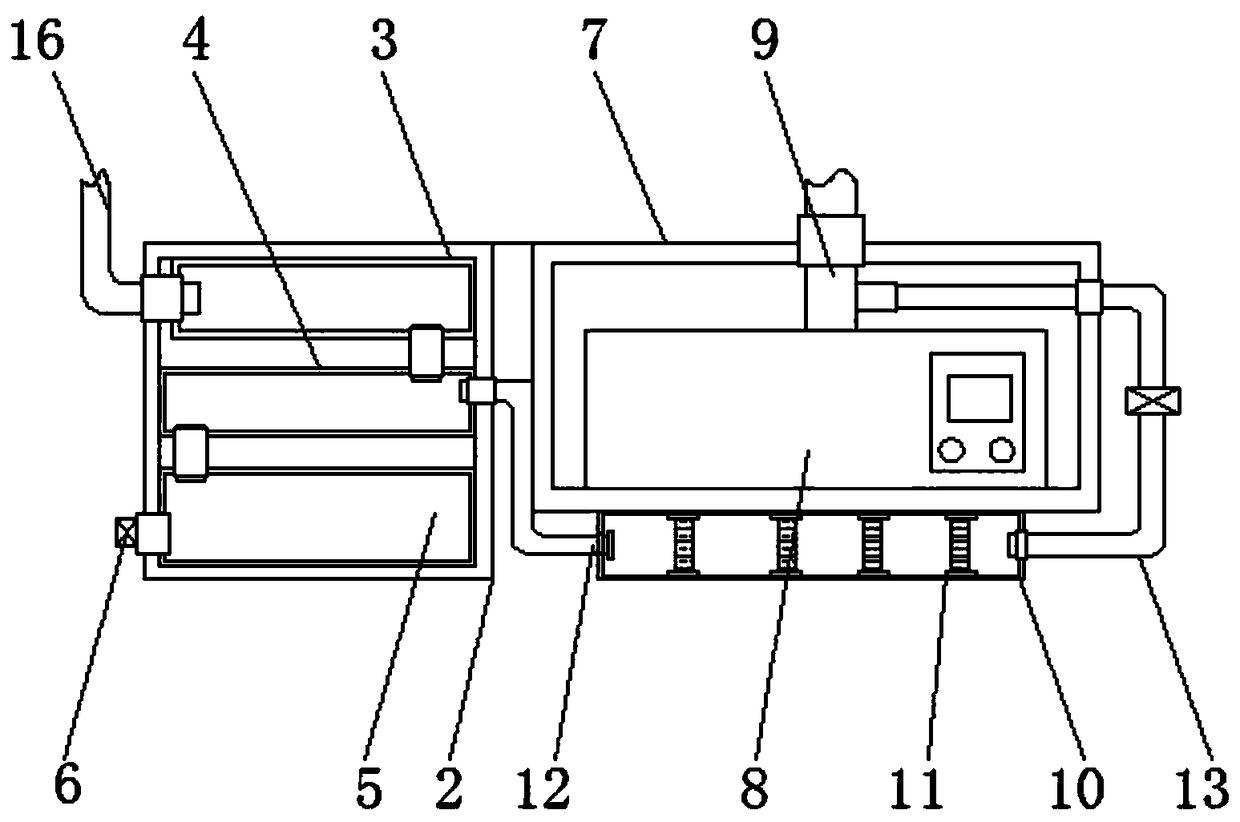

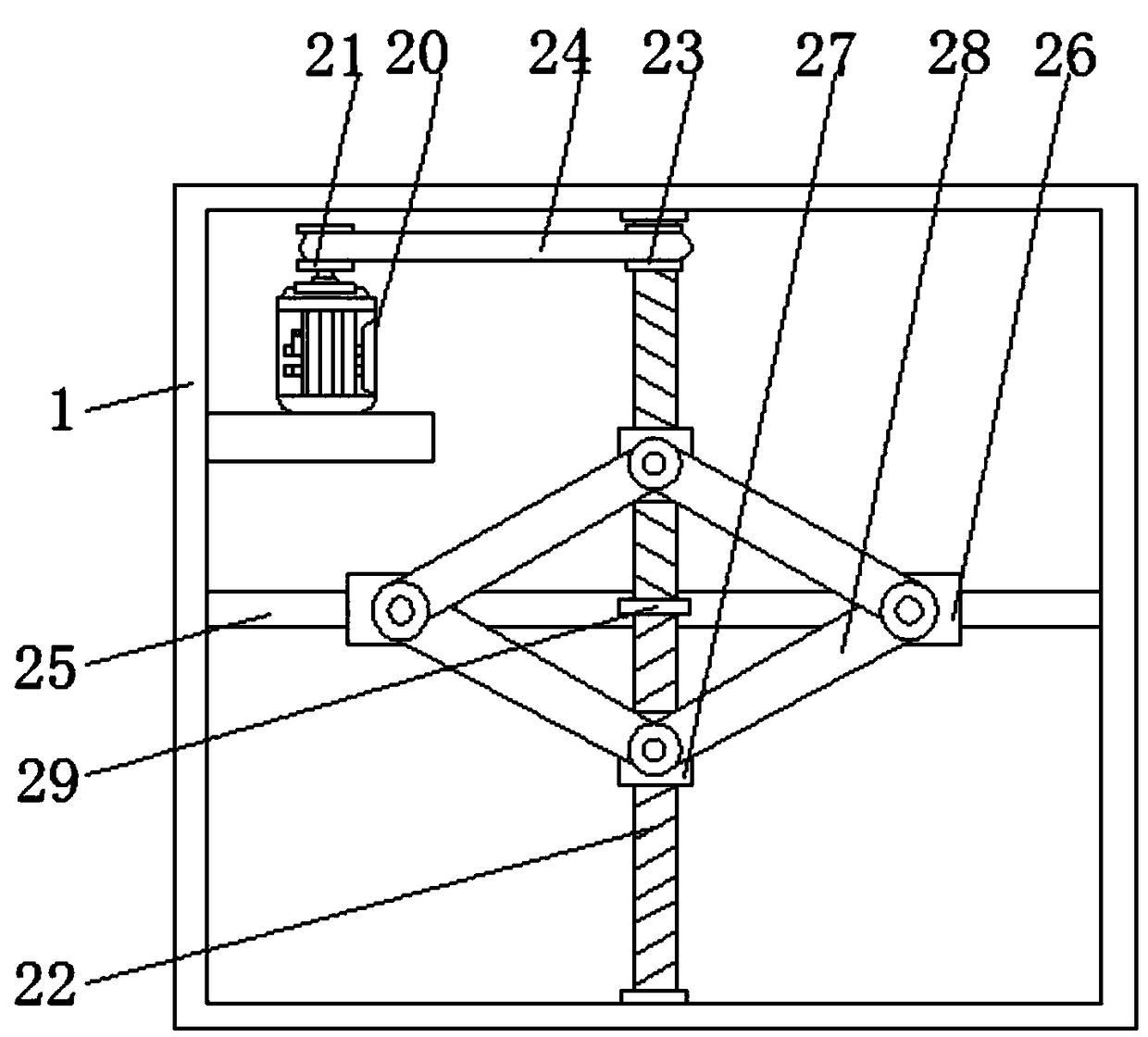

[0025] The present invention provides a technical solution: a drying device for food testing, including a drying box 1, the bottom of the drying box 1 is fixedly connected with a collection box 2, and the top of the inner cavity of the collection box 2 is fixedly connected with a first condensation box 3. Between the two sides of the inner cavity of the collection box 2 and at the bottom of the first condensation box 3 is fixedly connected with the second condensation box 4, the bottom of the inner cavity of the collection box 2 is fixedly connected with the water collection box 5, the first condensation box 3 and The second condensing tank 4 is communicated by a communication pipe, and the second condensing tank 4 and the water collection tank 5 are communicated by a communication pipe. The bottom of the water collection tank 5 is communicated with a drain pipe 6, and the bottom of the drain pipe 6 runs through the collection tank 2 And extend to the bottom of the collection b...

Embodiment 2

[0028] A method for using a drying device for food testing. When working, the user starts the hot air blower 8, and after the hot air blower 8 is turned on, the hot air is transmitted to the connecting hose 14 through the output pipe 9, and then the connecting hose 14 transmits the hot air to the nozzle 15. In this way, the hot air is sent to the drying box 1 through the nozzle 15, and then the hot air dries the food on the mesh plate 19. After the hot air dries the food, it will enter the air collecting pipe 16, and through the air collecting pipe 16, the hot air enters the first condensation pipe 3 After the hot air is condensed in the first condensation pipe 3, its moisture is converted into gas and moisture, and then the gas and moisture enter the second condensation pipe 4 through the communication pipe, and a small amount of moisture appears after the gas is condensed again in the second condensation pipe 4, and then water Flow into the water collection tank 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com