A strut spacing mechanism for air-drying and drying vermicelli

A technology of a powder skin and a support part is applied in the field of a strut spacing mechanism for drying the powder skin, which can solve the problems that the contact surface between the powder skin and the drying screen cannot be air-flowed, and the powder skin drying rack occupies a large space, and achieves better cooking effect. Excellent, simple structure, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

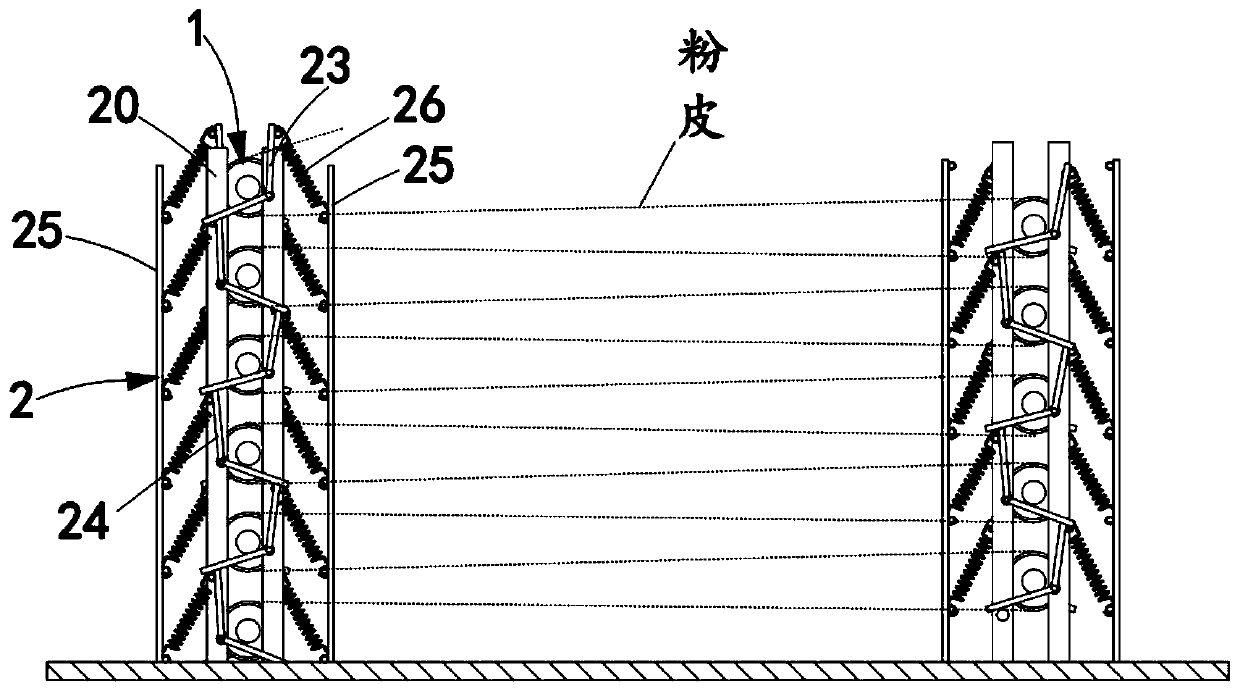

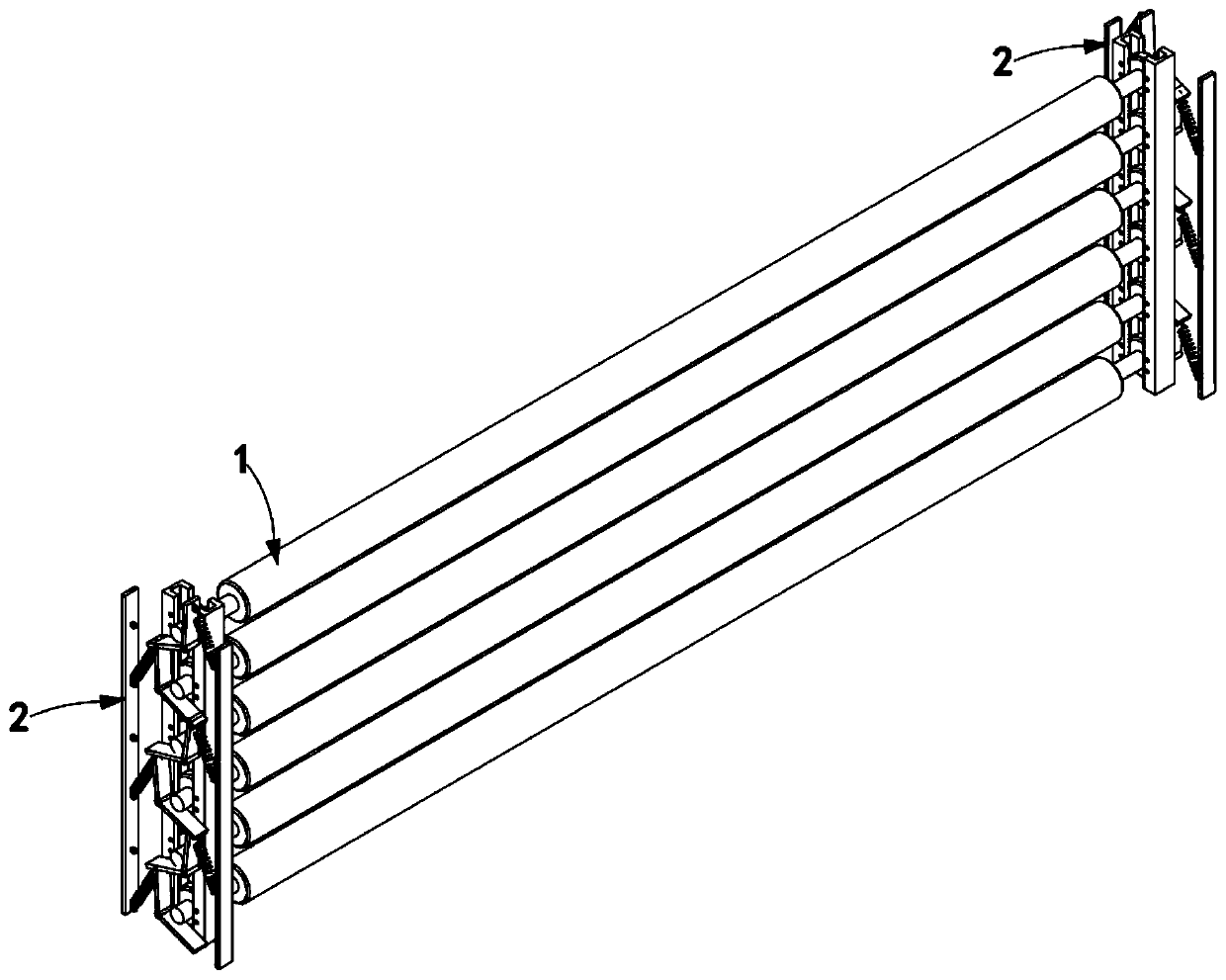

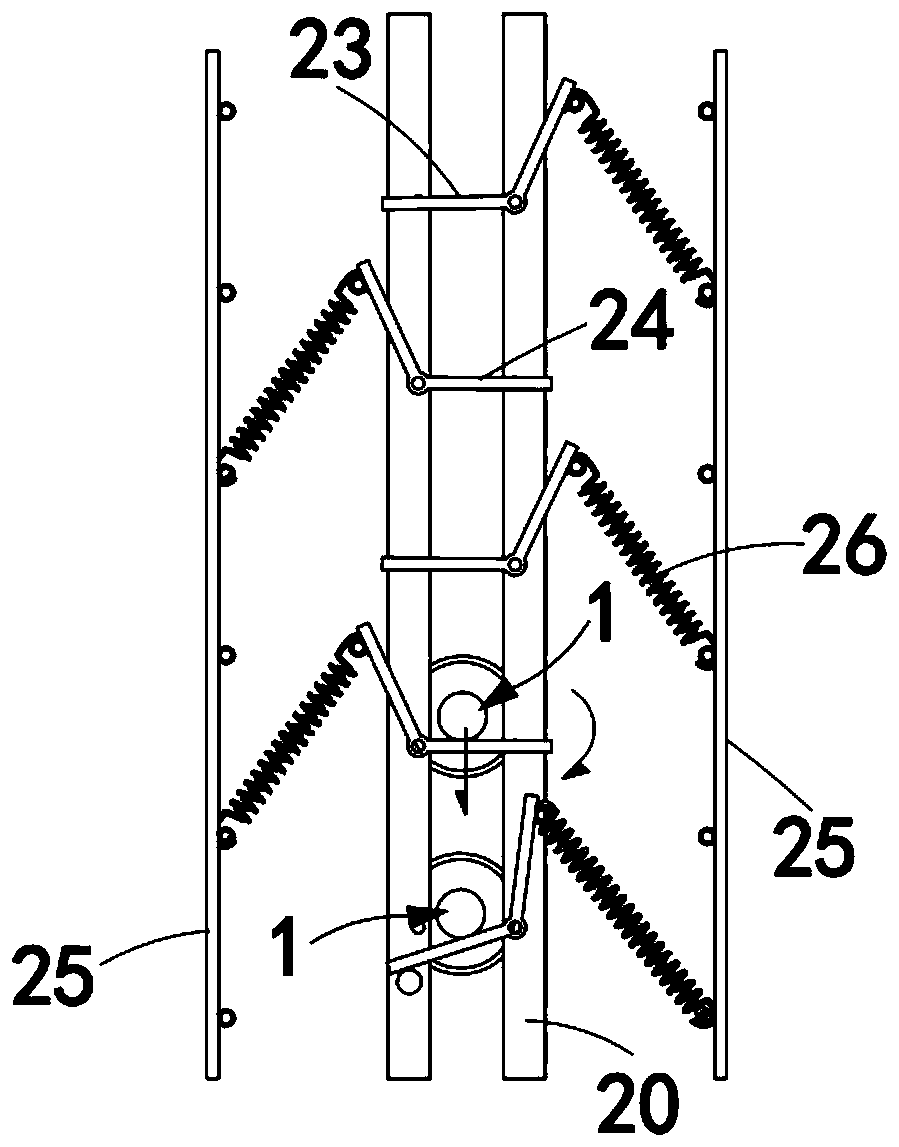

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, a strut spacer mechanism for air-drying and drying of vermicelli comprises several struts 1, and the struts 1 all include:

[0049] A support portion 11, the support portion 11 is configured in a cylindrical shape;

[0050] A connecting shaft 12, the connecting shaft 12 is symmetrically arranged on both sides of the supporting part 11, and the connecting shaft 12 is coaxially connected with the supporting part 11;

[0051] A circular chuck 13, the circular chuck 13 is arranged on the connecting shaft 12, and the chuck 13 is coaxially connected with the supporting part 11 through the connecting shaft 12;

[0052] It also includes a spacing mechanism 2, the spacing mechanism 2 is symmetrically arranged on both sides of the strut 1, the circular chuck 13 is engaged with the spacing mechanism 2, and the connecting shaft 12 is connected to the spacing mechanism 2. Agency 2 conflicts with settings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com