An Adaptive Design Method for Supercritical Carbon Dioxide Turbine

A carbon dioxide, design method technology, applied in special data processing applications, geometric CAD, CAD numerical modeling, etc., can solve the problems of long design cycle and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

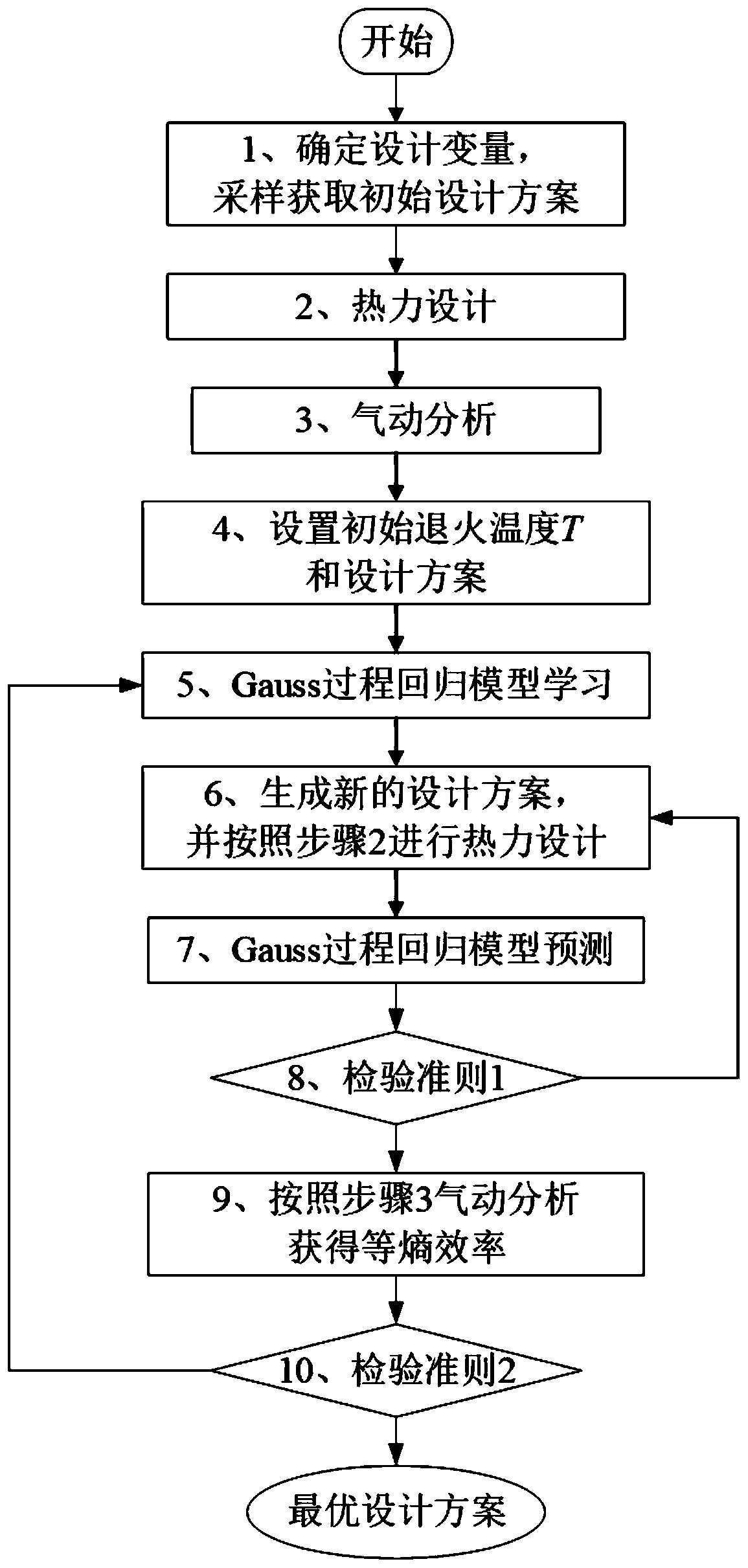

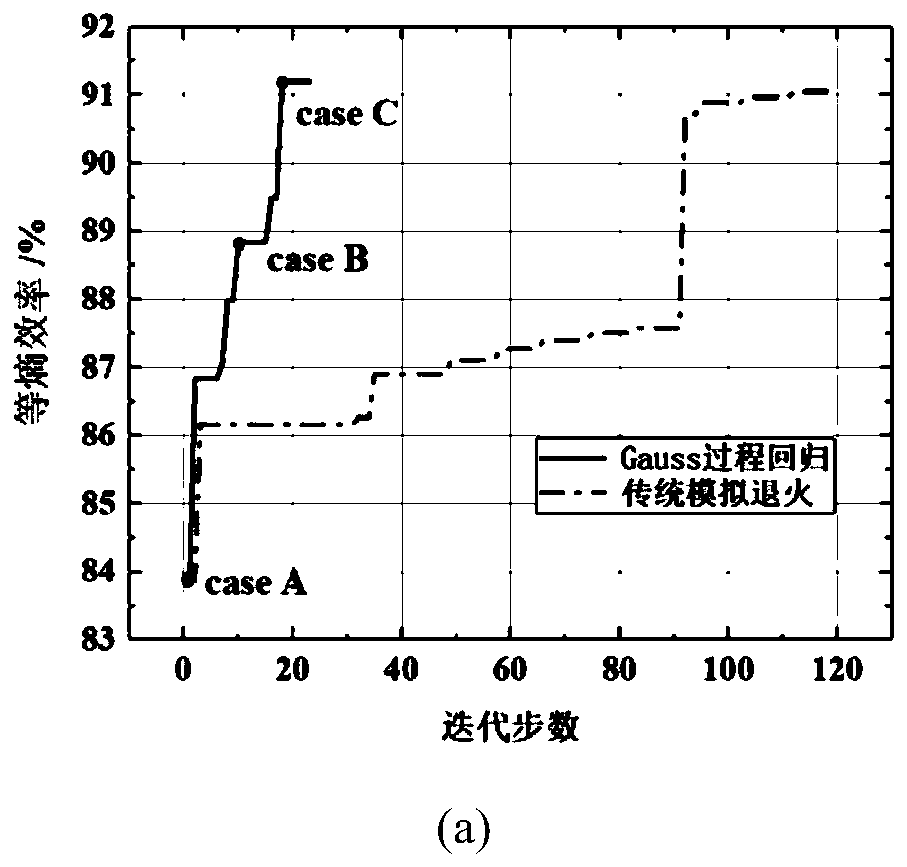

[0203] see Figure 1 to Figure 5 , utilizing a kind of self-adaptive supercritical carbon dioxide turbine design method provided by the present invention, a 450kW supercritical carbon dioxide turbine has been designed-optimized, specifically as follows:

[0204] a) Design parameters

[0205] The key thermal design parameters of the supercritical carbon dioxide turbine are shown in Table 1. The design power is 450 kW, the speed is set at 40,000 rpm, the temperature and pressure at the nozzle inlet are 505 °C and 13.9 MPa, respectively, and the impeller outlet pressure is 7.85 MPa.

[0206] Table 1 Thermal design parameters

[0207]

[0208] b) Initial Design Scheme

[0209] According to general design experience and thermal design parameters, the initial design scheme of supercritical carbon dioxide turbine can be obtained, and its key parameters are shown in Table 2.

[0210] Table 2 Key parameters of the initial design scheme

[0211]

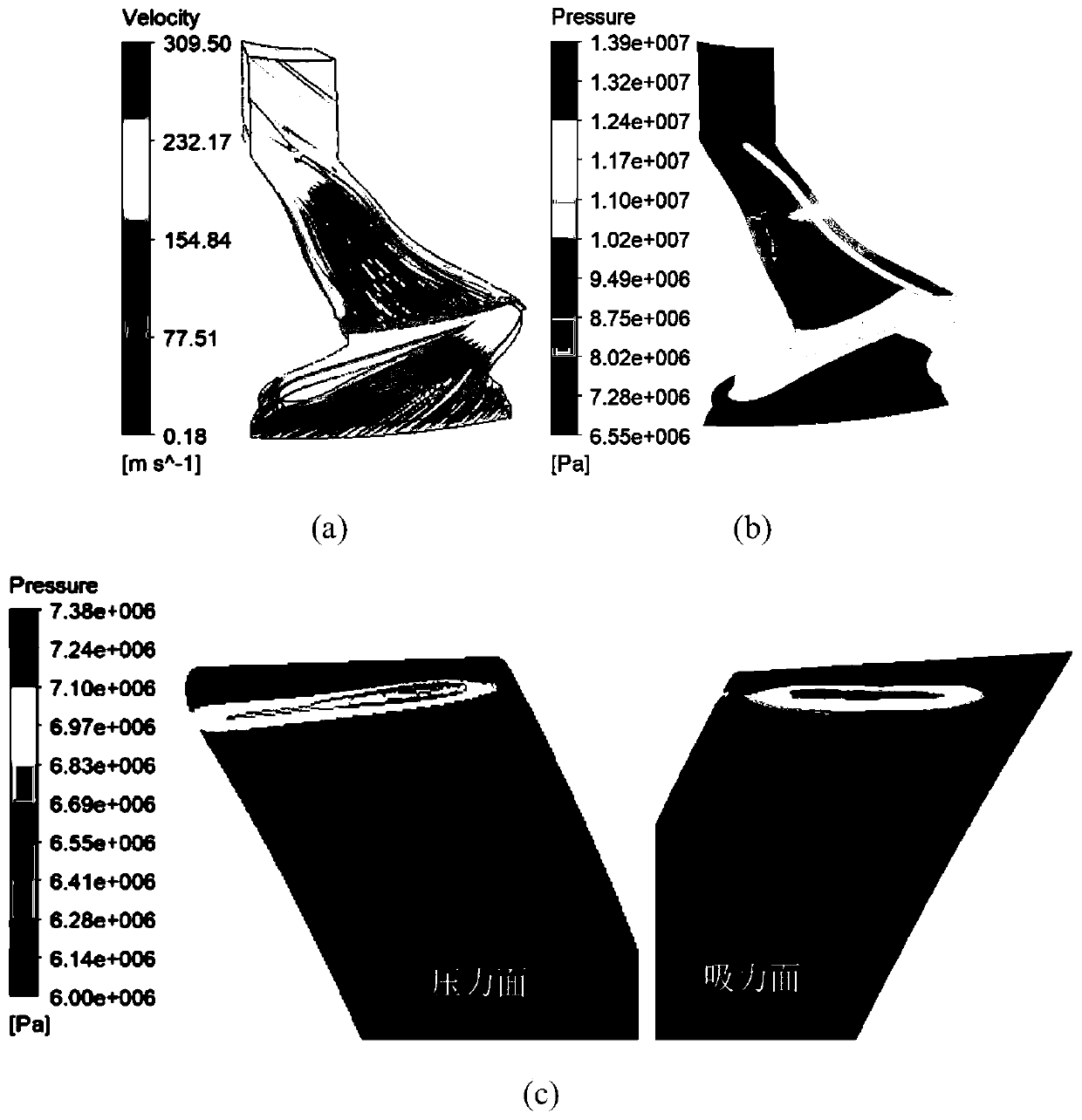

[0212] figure 2 The three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com