Method for preventing gold plating lateral erosion and gold finger copper exposure of printed circuit boards

A printed circuit board and circuit board technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary processing, etc., can solve the problems of exposed copper on gold fingers, inability to apply gold on gold fingers, and increased cost of printed circuit boards. The effect of preventing gold-plated side corrosion and preventing gold fingers from exposing copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

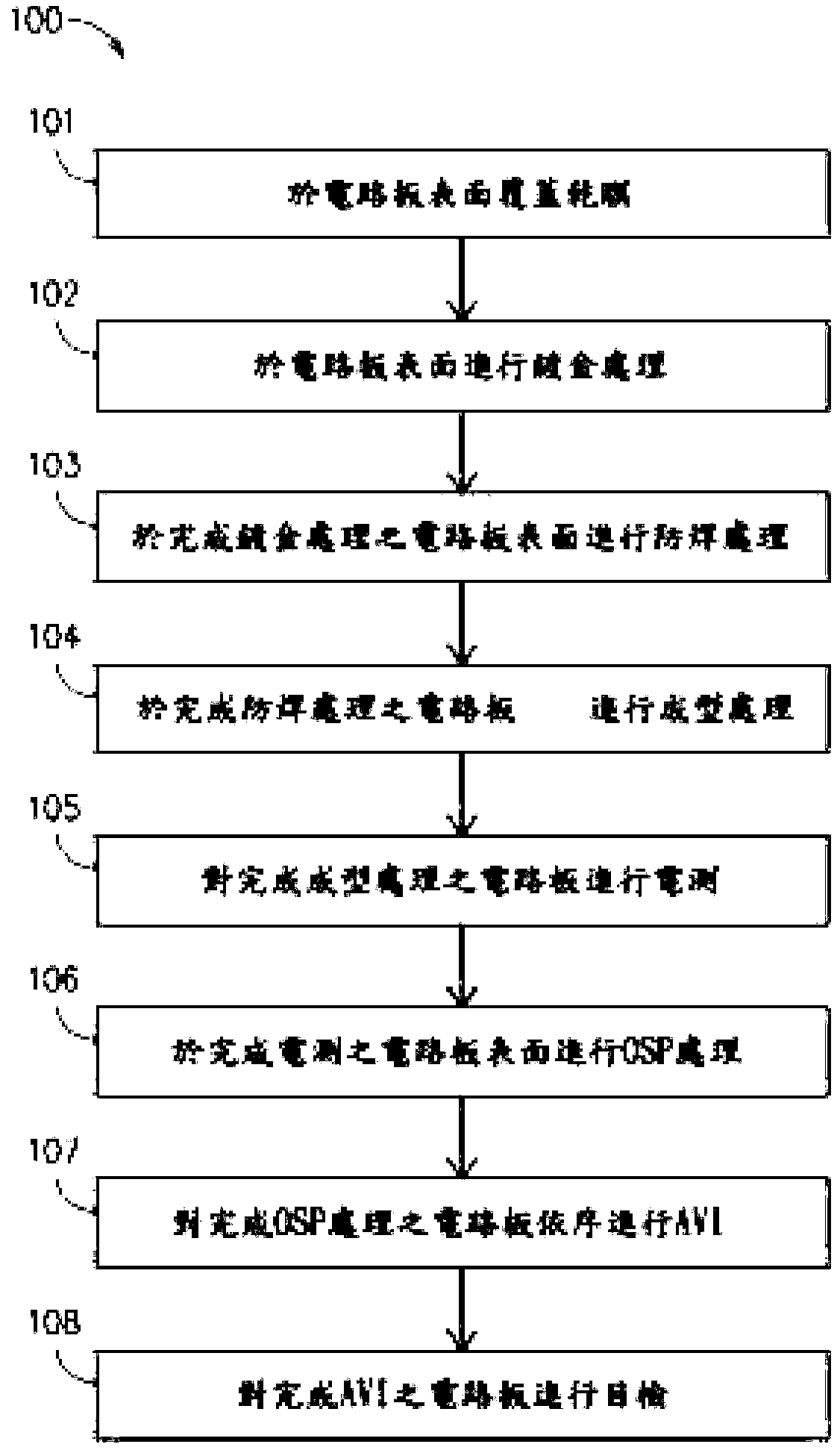

[0039] see figure 1 As shown, a method flow 100 for preventing underside corrosion of gold-plated printed circuit boards and exposed copper on gold fingers provided by the present invention includes the following steps:

[0040] Step 101: Cover the surface of the circuit board with a dry film; cover the dry film where no gold plating is required;

[0041] Step 102: performing gold plating on the surface of the circuit board;

[0042] Step 103: Solder resist treatment is performed on the surface of the gold-plated circuit board; the solder resist treatment is to use ink to protect parts that do not need to be soldered.

[0043] Step 104: Carry out molding treatment on the circuit board that has completed the solder mask treatment, and make it into the size required by the customer;

[0044] Step 105: Conduct electrical testing on the circuit board that has completed the molding process;

[0045] Step 106: Perform OSP (Organic Solderability Preservative, Organic Solderability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com