Preparation method of composite nano-carrageenan for food processing

A technology of food processing and carrageenan, applied in food preservation, application, food science, etc., can solve problems such as insolubility, achieve the effect of promoting gel strength, enhancing gel effect, and reducing syneresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

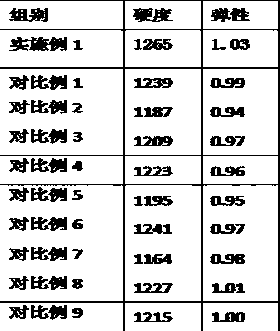

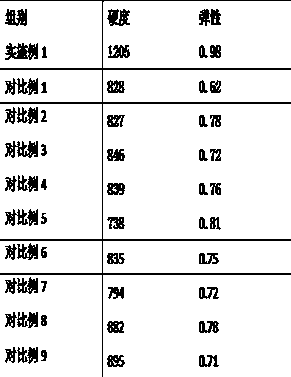

Examples

Embodiment 1

[0012] The preparation method of the composite nano-carrageenan is as follows: the soybean protein isolate solution with a mass concentration of 8% is mixed with the yeast-β-glucan solution according to the molar ratio of 1:3, stirred and mixed evenly, and the pH value of the solution is adjusted to 8.0 after the solution is evenly mixed or so, the solution was then freeze-dried. The freeze-dried solid powder is weighed, then placed in a beaker and placed in a closed container with KBr saturated solution (the relative humidity in the container is 80%), and after carrying out Maillard reaction at 60°C for 10 hours, soybean protein isolate is obtained - dextran covalent complex,

[0013] Soybean protein isolate-glucan covalent complex is dissolved with deionized water, then add nano-calcium, the mass ratio of nano-calcium and soybean protein isolate is 1: 5, after the solution is mixed evenly, adjust the pH of the mixed solution with NaOH to 8 to form a nanometer calcium-isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com