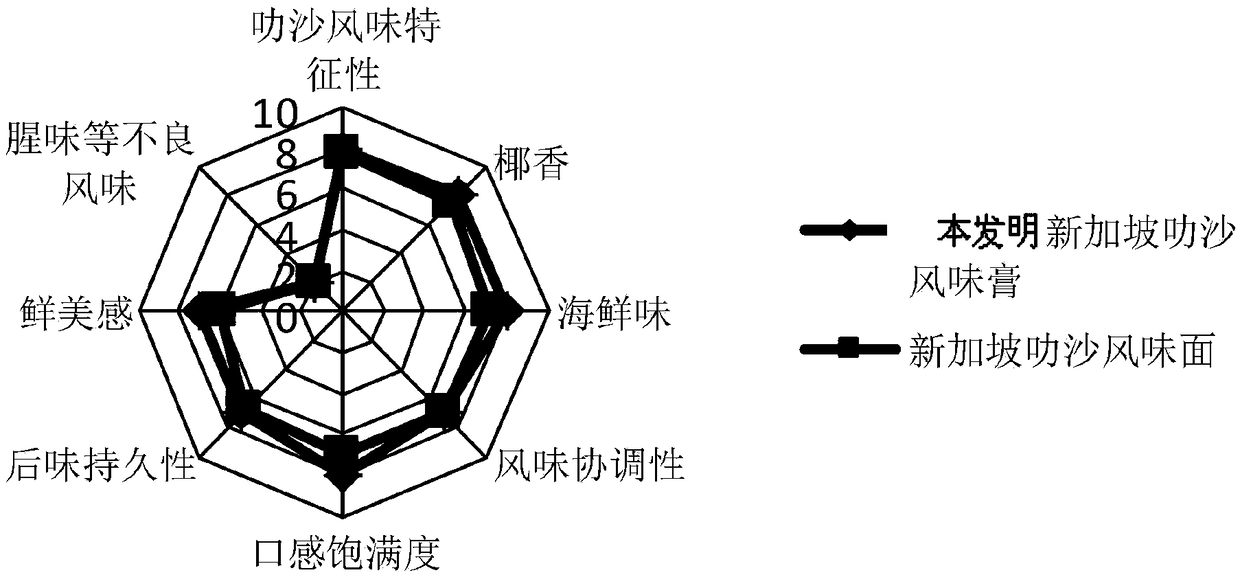

Singapore-laksa-flavor paste and preparation method thereof

A laksa-flavor paste, fresh technology, applied in the directions of food ingredients as taste improvers, food ingredients as taste improvers, food science, etc., can solve the problems of restricting the development of laksa-flavored laksa flavors and not yet finding patent publications and the like , to achieve the effect of improving accessibility and reactivity, strong characteristics, and promoting adsorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of Singapore laksa flavor paste, its composition and parts by weight are as follows:

[0032] 60 parts of coconut milk seafood enzymatic hydrolysis solution, 2 parts of yeast extract, 5 parts of compound spice oil, 5 parts of table salt, 5 parts of white sugar, and 5 parts of corn starch.

[0033] Further, the preparation steps of the coconut milk seafood enzymatic hydrolyzate are as follows:

[0034] ⑴ Raw material pretreatment

[0035] Choose fresh and ripe coconuts to remove the coconut shell and shell, pour out the coconut water, and set aside; take the coconut meat, peel off the seed coat, wash, cut into pieces, and mince; choose fresh clams, low-value shrimp, and low-value fish , cleaned, mixed in a mass ratio of 1:3:1, minced to obtain a seafood mixture, then mixed with minced coconut meat and coconut water, passed through a colloid mill, and homogenized to obtain a mixed solution;

[0036] ⑵Segmented enzymatic hydrolysis

[0037] Add enzyme preparation...

Embodiment 2

[0047] A kind of Singapore laksa flavor paste, its composition and parts by weight are as follows:

[0048] 80 parts of coconut milk seafood enzymatic hydrolysis solution, 5 parts of yeast extract, 10 parts of compound spice oil, 10 parts of table salt, 10 parts of white sugar, and 10 parts of corn starch.

[0049] Further, the preparation steps of the coconut milk seafood enzymatic hydrolyzate are as follows:

[0050] ⑴ Raw material pretreatment

[0051]Choose fresh and ripe coconuts to remove the coconut shell and shell, pour out the coconut water, and set aside; take the coconut meat, peel off the seed coat, wash, cut into pieces, and mince; choose fresh clams, low-value shrimp, and low-value fish , cleaned, mixed in a mass ratio of 1:3:1, minced to obtain a seafood mixture, then mixed with minced coconut meat and coconut water, passed through a colloid mill, and homogenized to obtain a mixed solution;

[0052] ⑵Segmented enzymatic hydrolysis

[0053] Add enzyme preparat...

Embodiment 3

[0064] A kind of Singapore laksa flavor paste, its composition and parts by weight are as follows:

[0065] 60 parts of coconut milk seafood enzymatic hydrolysis solution, 5 parts of yeast extract, 10 parts of compound spice oil, 5 parts of table salt, 10 parts of white sugar, 10 parts of corn starch;

[0066] Preferably, the preparation steps of the coconut milk seafood enzymatic hydrolyzate are as follows:

[0067] (1) Raw material pretreatment

[0068] Choose fresh and ripe coconuts to remove the coconut shell and shell, pour out the coconut water, set aside, take the coconut meat, peel off the seed coat, wash, cut into pieces, and mince; choose fresh clams, low-value shrimp, and low-value fish , cleaned, mixed in a mass ratio of 1:3:1, ground, mixed with ground coconut meat and coconut water, passed through a colloid mill, and homogenized;

[0069] (2) Segmented enzymatic hydrolysis

[0070] Add the enzyme preparation A of 0.1-1% coconut meat weight in the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com