Static rotational flow emulsion-breaking device and application thereof

A demulsification device and electrostatic technology, which is applied in the application field of demulsification treatment, can solve the problems of affecting the working stability of the device, reducing the collision frequency of water droplets, and worsening the coalescence effect, so as to achieve the enhancement of swirl strength and the increase of residence time. , the effect of improving the efficiency of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

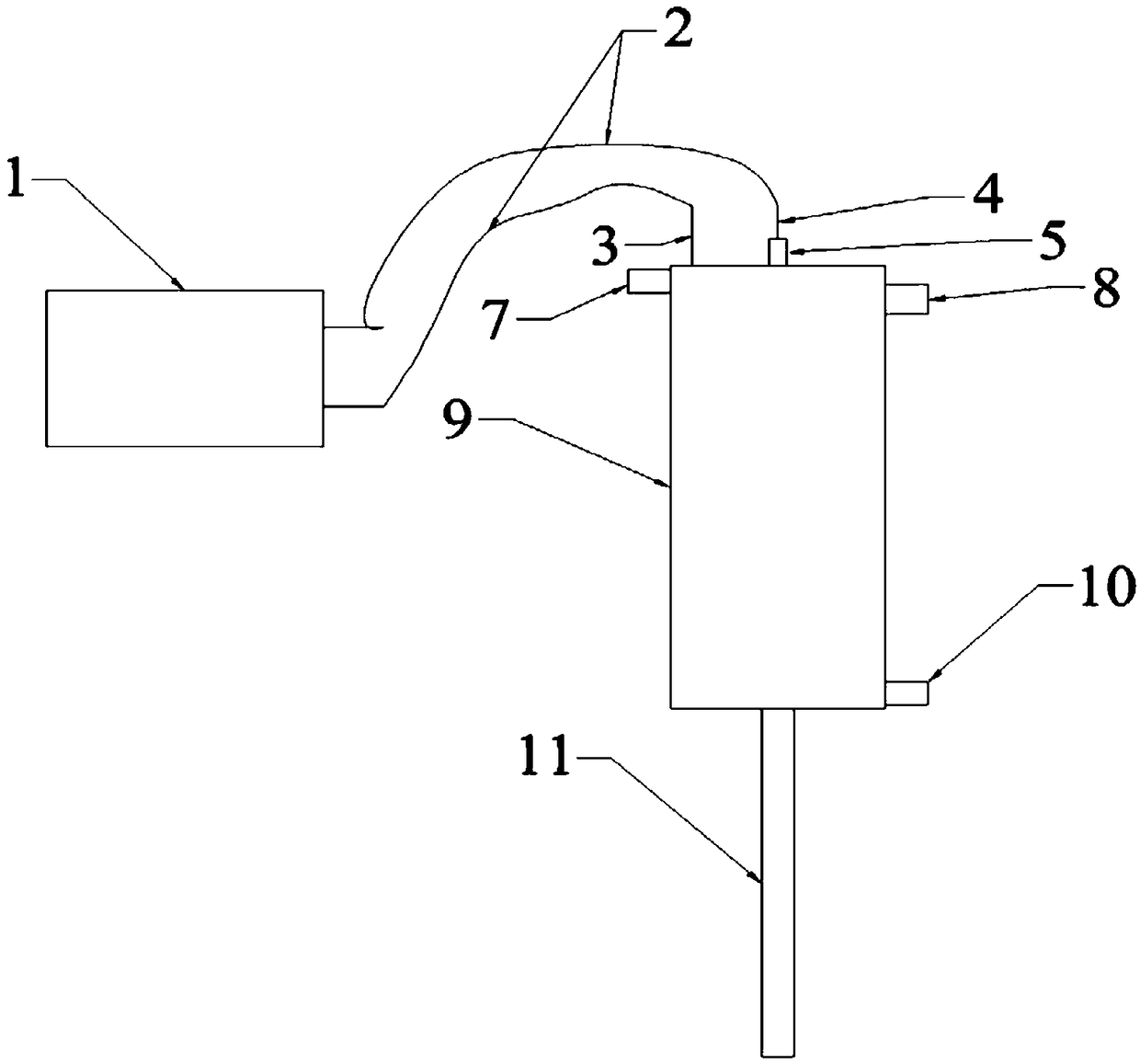

[0028] In this embodiment, the electrostatic cyclone demulsification device such as figure 1 , figure 2 , image 3 As shown, it includes an insulating demulsification main body, an insulating shell 9, an electrode assembly and a power generator 1. Power generator 1 is mainly composed of a high-voltage pulse power supply (Guangxin JC-12) and a signal generator (MFG-3005CH). The signal generator is used to input waveform signals to the high-voltage pulse power supply. Output high voltage pulse signal after waveform signal.

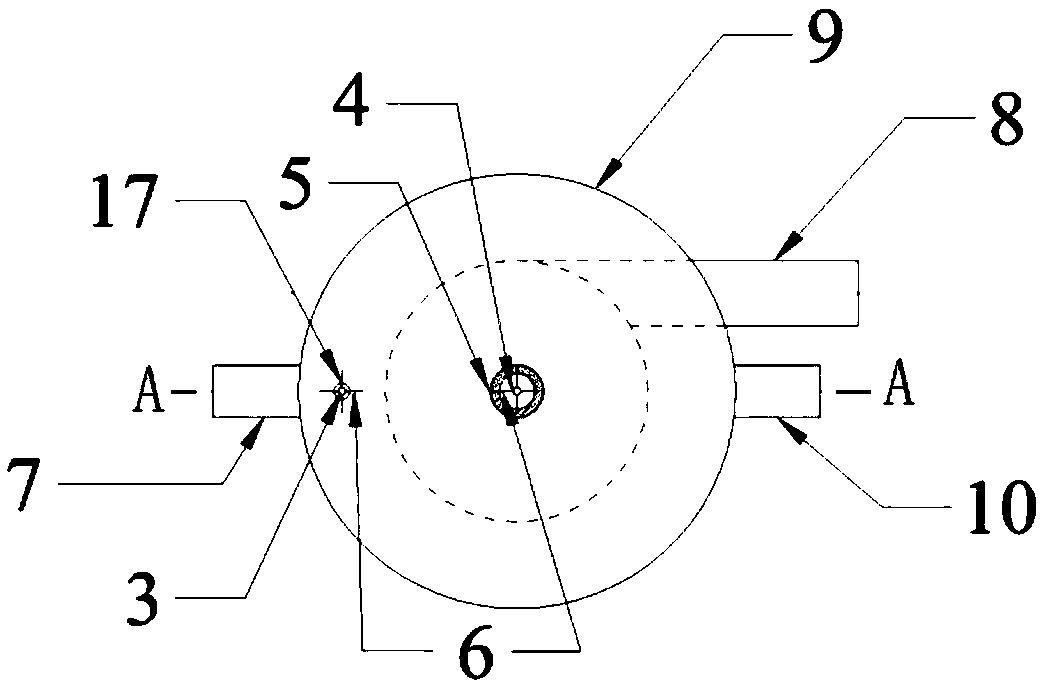

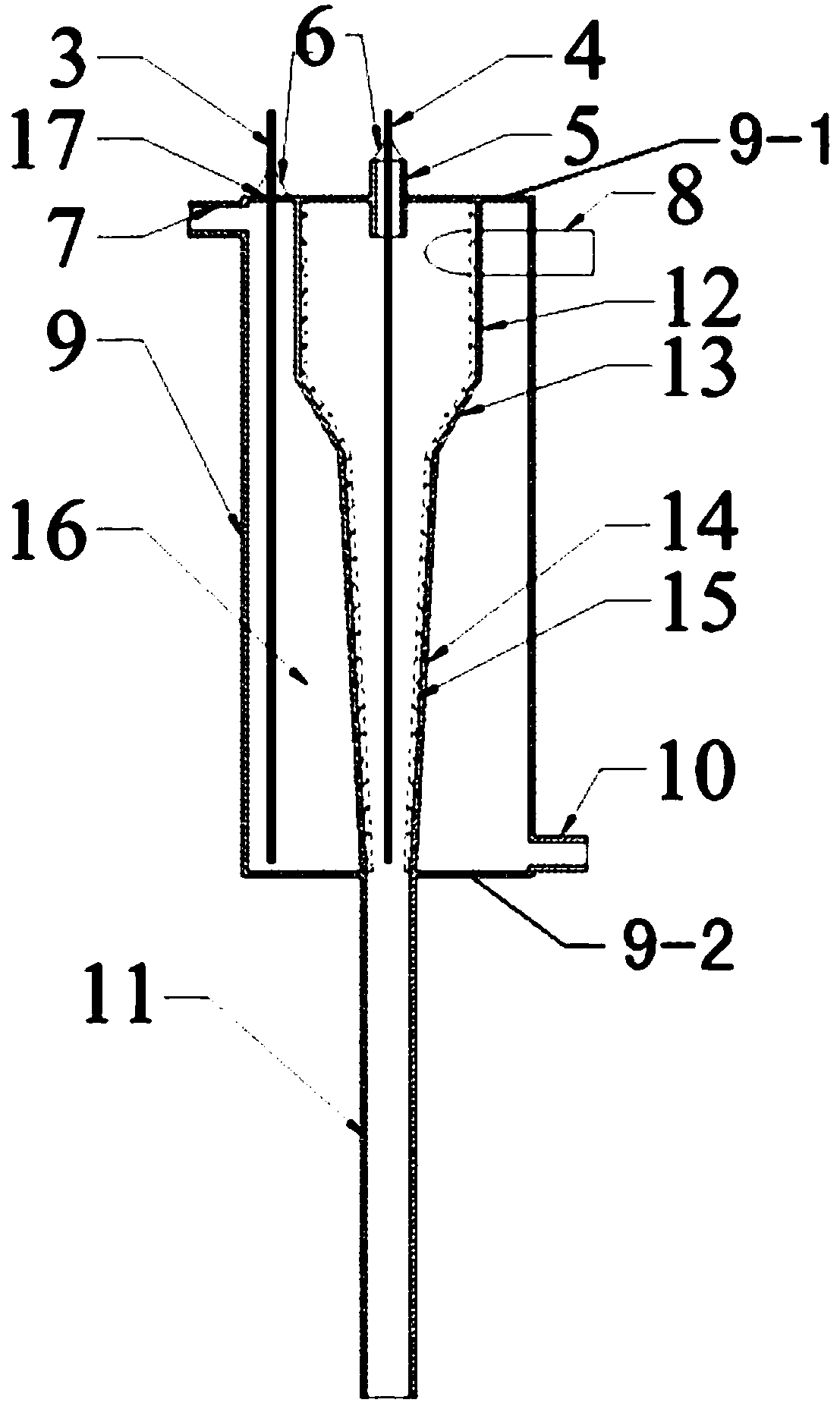

[0029] Such as image 3 As shown, the electrode assembly is composed of a first insulated electrode 3 and a second insulated electrode 4 .

[0030] Such as image 3 , Figure 4 As shown, the insulating demulsification main body is composed of a cylindrical section chamber 12, a first cone section chamber 13, a second cone section chamber 14 and a tailpipe 11 whose center line is on a straight line from top to bottom; the cylindrical section chamber T...

Embodiment 2

[0034] In this example, the electrostatic cyclone demulsification device described in Example 1 is used to break the water-in-oil emulsion with the mixture of kerosene and tributyl phosphate as the continuous phase and wet-process phosphoric acid as the dispersed phase. The water-in-oil emulsion is composed of 1000mL kerosene, 1500mL tributyl phosphate and 500mL wet-process phosphoric acid, with a volume of 3000mL.

[0035] Demulsification treatment operation:

[0036] ①Inject 2000mL of NaCl solution with a mass concentration of 1.0% into the annular cavity 16 between the outer wall of the insulating demulsification main body and the inner wall of the insulating shell, then turn on the power generator 1, and adjust the pulse electric field strength and frequency to 5kV / cm and 800Hz;

[0037] ②The above-mentioned water-in-oil emulsion is input into the insulating demulsification main body from the feed pipe 8 at a volume flow rate of 12.8L / min, and under the action of centrifu...

Embodiment 3

[0043] In this embodiment, the electrostatic cyclone demulsification device such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes an insulating demulsification main body, an insulating shell, an electrode assembly and a power generator.

[0044] The difference from Example 1 is:

[0045] 1. Relevant dimensions of the demulsification main body: the height L1=40mm, the inner diameter D=20mm of the cylindrical section chamber 12, the inner diameter Do=4mm of the overflow pipe, the length extending into the cylindrical section chamber=8mm, the length of the feed pipe Inner diameter Di=8mm; The inner diameter of the first taper section chamber 13 upper ends is identical with the inner diameter D of the cylindrical section chamber, the inner diameter D1=10mm of the lower end, cone angle α=20 °; The inner diameter of the second taper section chamber 14 upper ends is the same as The inner diameter D1 of the lower end of the chamber of the first cone section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com