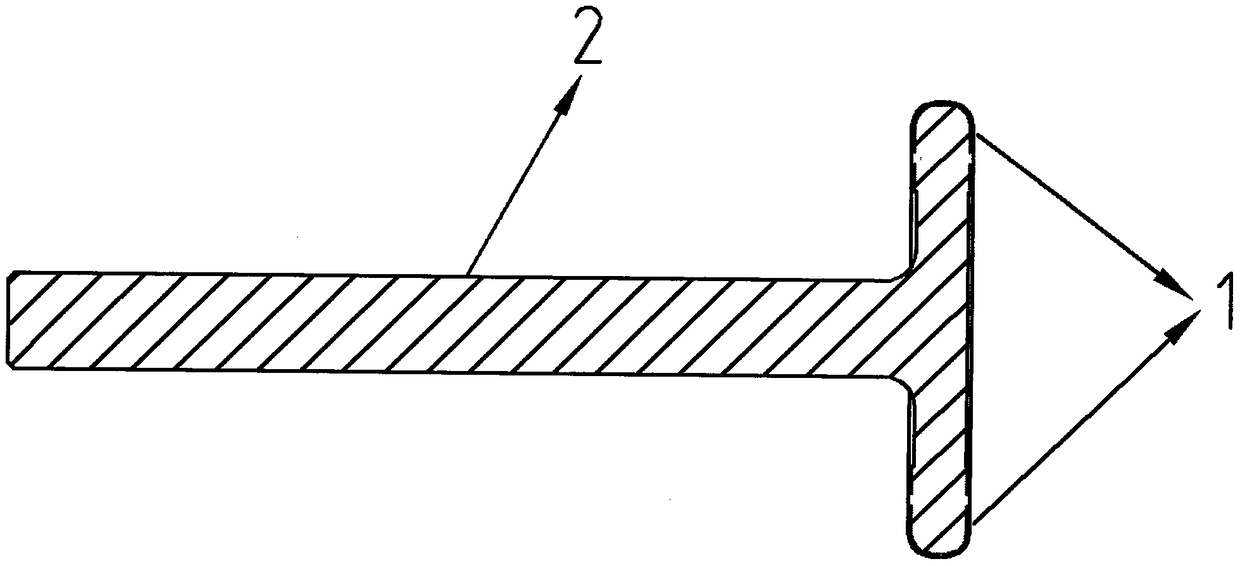

Novel engine cylinder robot grinding head

An engine block and robot technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of frequent replacement, short life, frequent compensation of processing parameters, replacement of tools, etc., to avoid parameter compensation and good shape retention , to achieve the effect of industrial automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

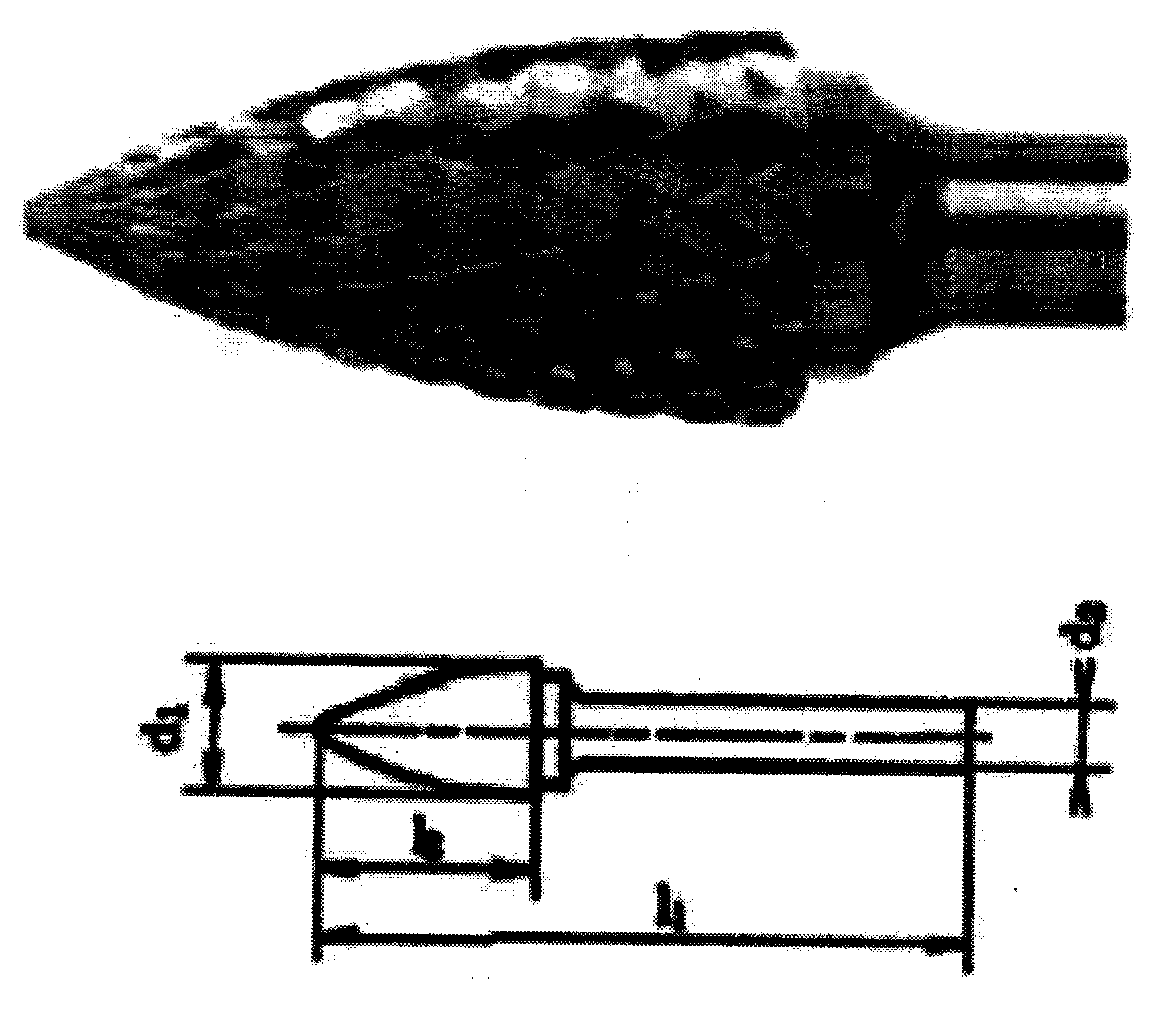

[0017] Take the processing of cast iron engines as an example:

[0018] 1. Carry out quenching and tempering treatment on the bearing steel round bar, the quenching and tempering hardness is HRC38-42, the current general grinding wheel rod does not need quenching and tempering, the hardness is HRC15-25;

[0019] 2. Use a precision CNC lathe to turn the grinding head base, the size is controlled at ±7μm, the runout and coaxiality are controlled at 5μm, and the surface finish is as small as 0.8μm;

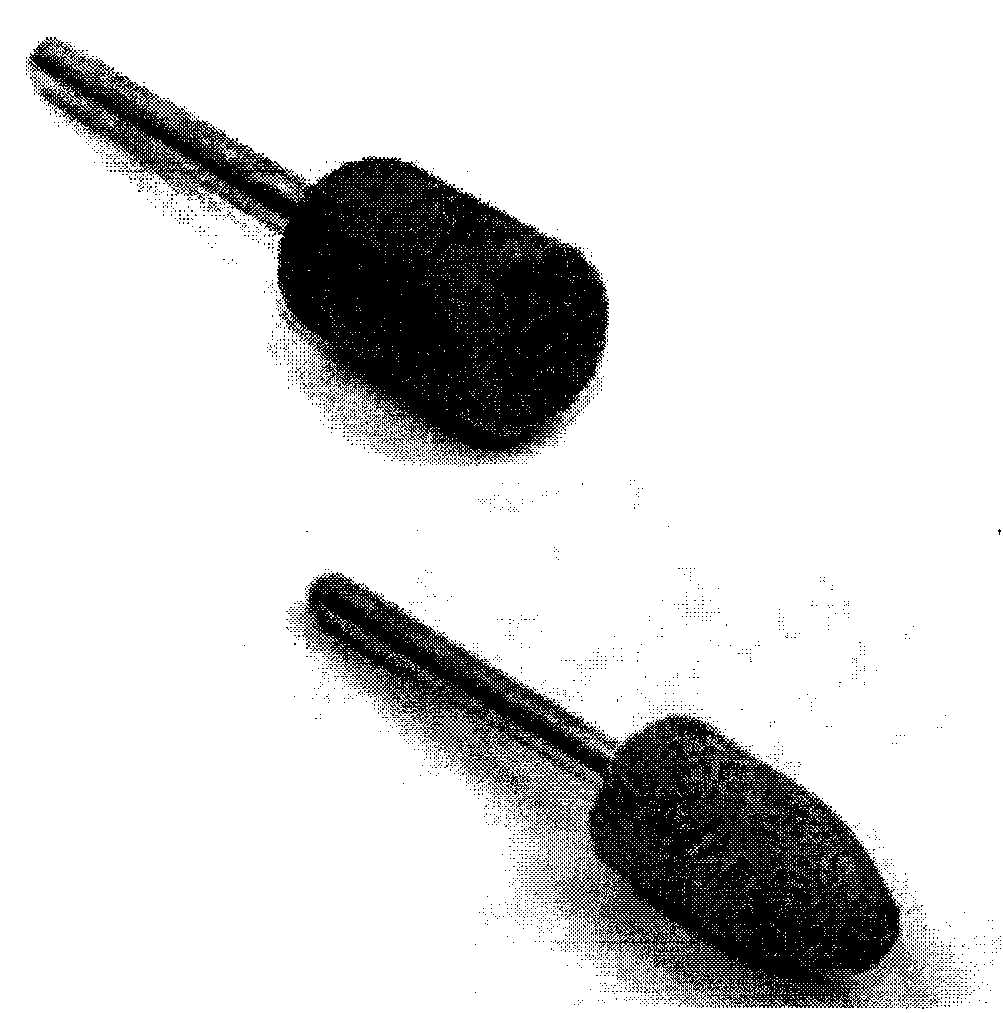

[0020] 3. Choose a medium-strength sharp diamond to clean and reserve, and the abrasive is normal abrasive;

[0021] 4. According to the electrochemical principle, the embedding sand method is used to make it, and the abrasive embedding rate is controlled at 20-25%, which is under normal control;

[0022] 5. The upper shielding splint is thickened, and the final abrasive embedding rate is controlled between 60% and 65%;

[0023] 6. Trim the contour of the grinding head to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com