Manufacturing method of fir softener

A production method and softener technology, which are applied in the field of fir treatment, can solve the problems of polluting the environment, easily causing waste products, etc., and achieve the effects of prolonging drying time, fast softening speed, and enhancing softening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

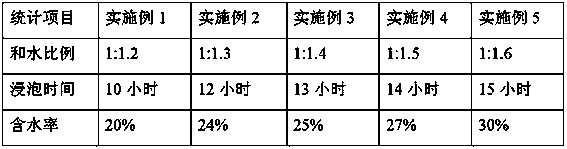

Examples

Embodiment 1

[0019] A kind of preparation method of Chinese fir softener, comprises the following steps:

[0020] A. Wash the Dahua Laoyazui and cut it into sections. After cutting, the length of each section does not exceed 30 cm, and then mix it with water in a weight ratio of 1:0.4, then use a machine to crush it, and filter it to obtain Dahua Laoyazui. juice spare;

[0021] B, after peeling the yam, crush it with a machine, then add the Dahua Laoyazui juice obtained in step A in a weight ratio of 1:0.8 and stir evenly to obtain a mixed solution;

[0022] C. Put the mixed solution obtained in step B into a container and heat it with high heat. After heating to boiling, continue heating with medium heat for 20 minutes, and keep stirring in the same direction during heating;

[0023] D. After the heating is completed, filter, remove impurities and then package, and leave it in a dark and cool place for 24 hours to obtain the Chinese fir softener.

Embodiment 2

[0025] A kind of preparation method of Chinese fir softener, comprises the following steps:

[0026] A. Wash the purple cicada flower and cut it into sections. After cutting, the length of each section is not more than 30 cm, then mix it with water in a weight ratio of 1:0.5, then use a machine to crush it, and filter it to obtain the purple cicada flower juice for later use ;

[0027] B, after the yam is peeled, crush it with a machine, then add the purple cicada juice obtained in step A in a weight ratio of 1:0.9 and stir evenly to obtain a mixed solution;

[0028] C. Put the mixed solution obtained in step B into a container and heat it with high heat. After heating to boiling, continue heating with medium heat for 23 minutes, and keep stirring in the same direction during heating;

[0029] D. After the heating is completed, filter, remove impurities and then package, and leave it in a dark and cool place for 26 hours to obtain the Chinese fir softener.

Embodiment 3

[0031] A kind of preparation method of Chinese fir softener, comprises the following steps:

[0032] A. Wash Aristolochia and cut into sections. The length of each section after cutting is not more than 30 cm, then mix with water in a weight ratio of 1:0.6, then use a machine to crush, and filter to obtain Aristolochia juice for later use ;

[0033] B, after the yam is peeled, crush it with a machine, then add the Aristolochia juice obtained in step A in a weight ratio of 1:1 and stir evenly to obtain a mixed solution;

[0034] C. Put the mixed solution obtained in step B into a container and heat it with high heat. After heating to boiling, continue heating with medium heat for 26 minutes, and keep stirring in the same direction during heating;

[0035] D. After the heating is completed, filter, remove impurities and then package, and stand in a dark and cool place for 30 hours to obtain the Chinese fir softener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com