Mechanical intelligent finish processing method for separating multiple materials from comprehensive waste plastic

A technology of mechanical intelligence and waste plastics, applied in plastic recycling, mechanical material recycling, chemical instruments and methods, etc., can solve the problems of low purity of waste plastics, high impurities, high labor costs, saving labor costs and low energy consumption , the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

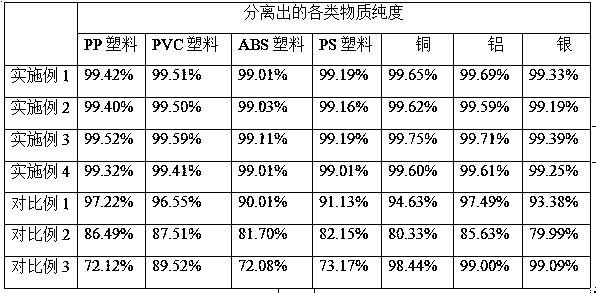

Embodiment 1

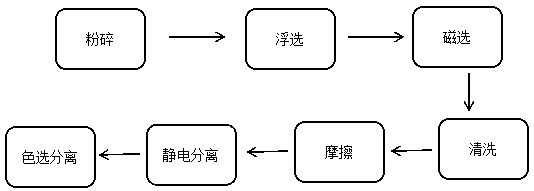

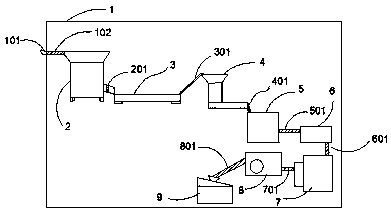

[0047] Embodiment 1 A mechanical intelligent finishing method for sorting multiple materials from comprehensive waste plastics, specifically including the following steps:

[0048] S1. Crushing: Crushing waste electrical plastics into sheets, passing through a sieve of 18mm;

[0049] S2. Flotation: Put the material obtained in step S1 into a vibrating fluid shaker separator, add tap water, and separate to obtain floating water and sinking water; then filter the floating water and sinking water separately, leave the filter residue, and use 15% of the filter residue in the sinking water The brine is separated by flotation to obtain floating clear water material and sinking clear water material;

[0050] S3. Magnetic separation: transfer the filter residue and materials obtained in step S2 to a magnetic separation device, and magnetically separate the filter residue and materials in floating clear water and sinking clear water respectively to obtain metal materials, light compone...

Embodiment 2

[0055] Embodiment 2 A mechanical intelligent finishing method for sorting multiple materials from comprehensive waste plastics, specifically includes the following steps:

[0056] S1. Crushing: Break the waste electrical plastics into sheets, and pass the screen through 20mm;

[0057] S2. Flotation: Put the material obtained in step S1 into a vibrating fluid shaker separator, add tap water, and separate to obtain floating water and sinking water; then filter the floating water and sinking water respectively, leave the filter residue, and use 35% of the filter residue in the sinking water The calcium chloride solution is separated by flotation to obtain floating clear water material and sink clear water material;

[0058] S3. Magnetic separation: transfer the filter residue and materials obtained in step S2 to a magnetic separation device, and magnetically separate the filter residue and materials in floating clear water and sinking clear water respectively to obtain metal mate...

Embodiment 3

[0063] Embodiment 3 A mechanical intelligent finishing method for sorting multiple materials from comprehensive waste plastics, specifically including the following steps:

[0064] S1. Crushing: Break the waste electrical plastics into sheets, and pass the screen through 20mm;

[0065] S2. Flotation: Put the material obtained in step S1 into a vibrating fluid shaker separator, add tap water, and separate to obtain floating water and sinking water; then filter the floating water and sinking water separately, leave the filter residue, and use 20% of the filter residue in the sinking water The brine is separated by flotation to obtain floating clear water material and sinking clear water material;

[0066] S3. Magnetic separation: transfer the filter residue and materials obtained in step S2 to a magnetic separation device, and magnetically separate the filter residue and materials in floating clear water and sinking clear water respectively to obtain metal materials, light compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com