Rotary table filter distribution valve electric lifting device

An electric lifting device and filter technology, which is applied to portable lifting devices, hoisting devices, clockwork mechanisms, etc., can solve the problems of asynchronous lifting, hydraulic oil leakage, pollution of the environment, etc., to facilitate adjustment and maintenance, reduce Production cost, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

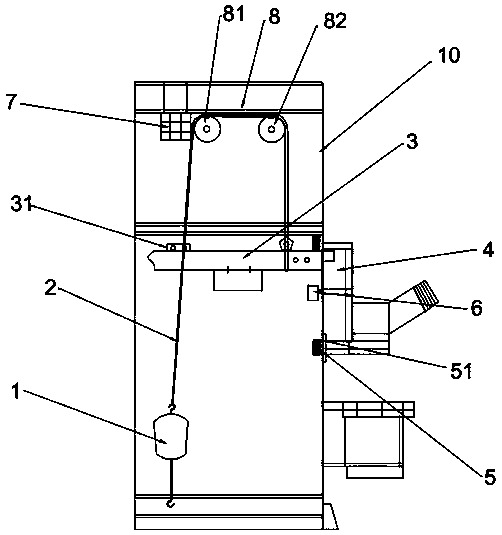

[0025] Please refer to figure 1 , the present invention provides a turntable filter distribution valve electric lifting device, the turntable filter includes a central column 10, the electric lifting device is integrally installed inside the central column 10, the electric lifting device includes an electric hoist 1, a steel wire rope 2, a lifting bracket 3, Elevate guide rail 4, travel switch 5 and mechanical protection device 6. The electric lifting device is integrally located inside the central column 10 and does not take up any external space, which is convenient for adjustment and maintenance of the filter.

[0026] The electric hoist 1 is located at the inner bottom of the center column 10, and the electric hoist 1 is used to provide power for the electric lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com