Preparation method of 2-bromo-1,1-difluoroethylene

A technology of vinylidene fluoride and vinylidene fluoride, which is applied in the field of preparation of 2-bromo-1,1-difluoroethylene, can solve the problems of strong corrosion of bromine and high requirements for equipment materials, achieve high purity, simple method, Post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of 2-bromo-1,1-difluoroethylene, comprising the following steps:

[0021] Under the copper catalyst, react N-bromosuccinimide and vinylidene fluoride in the presence of base and organic solvent to obtain 2-bromo-1,1-difluoroethylene.

[0022] The invention adopts N-bromosuccinimide and vinylidene fluoride as reaction raw materials to prepare 2-bromo-1,1-difluoroethylene, the method is simple, the post-treatment is simple and no waste water is required, and the by-products are directly recovered by suction filtration, which is environmentally friendly. Friendly, and the purity of the prepared product is high. The raw material vinylidene fluoride used is an industrial product, which is cheap and easy to obtain.

[0023] In the present invention, the vinylidene fluoride has the structure of formula I:

[0024]

Embodiment 1

[0039] Put 8.6g of cuprous bromide, 256.3g of NBS, 10.9g of cesium fluoride and 500ml of carbon tetrachloride into the 2L stainless steel reaction kettle in sequence, cool down to the internal temperature of 0°C, fill with vinylidene fluoride to 1.8MPa, and keep the temperature until pressure drops to zero;

[0040] The reaction liquid in the kettle is released, and the product 2-bromo-1,1-difluoroethylene is collected by low-temperature rectification, with a purity of more than 99.5%.

[0041] 105.2 g of cuprous bromide and succinimide were recovered by filtration of the rectification raffinate.

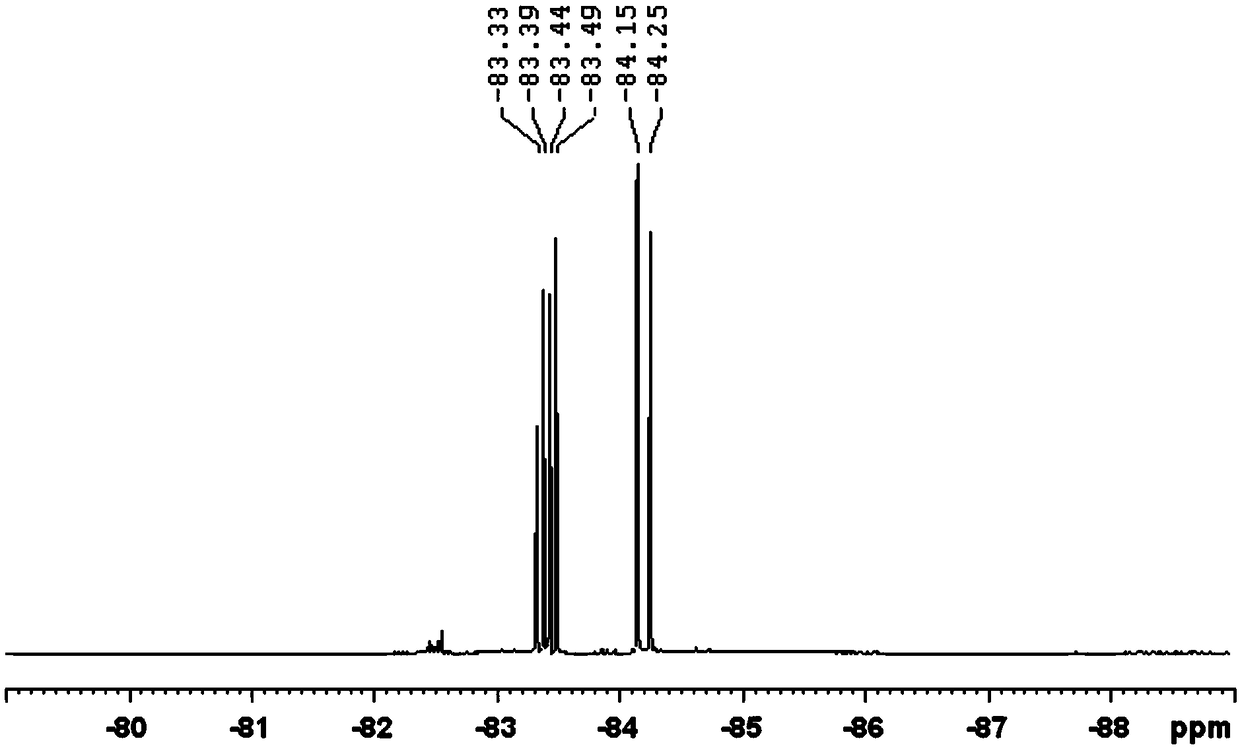

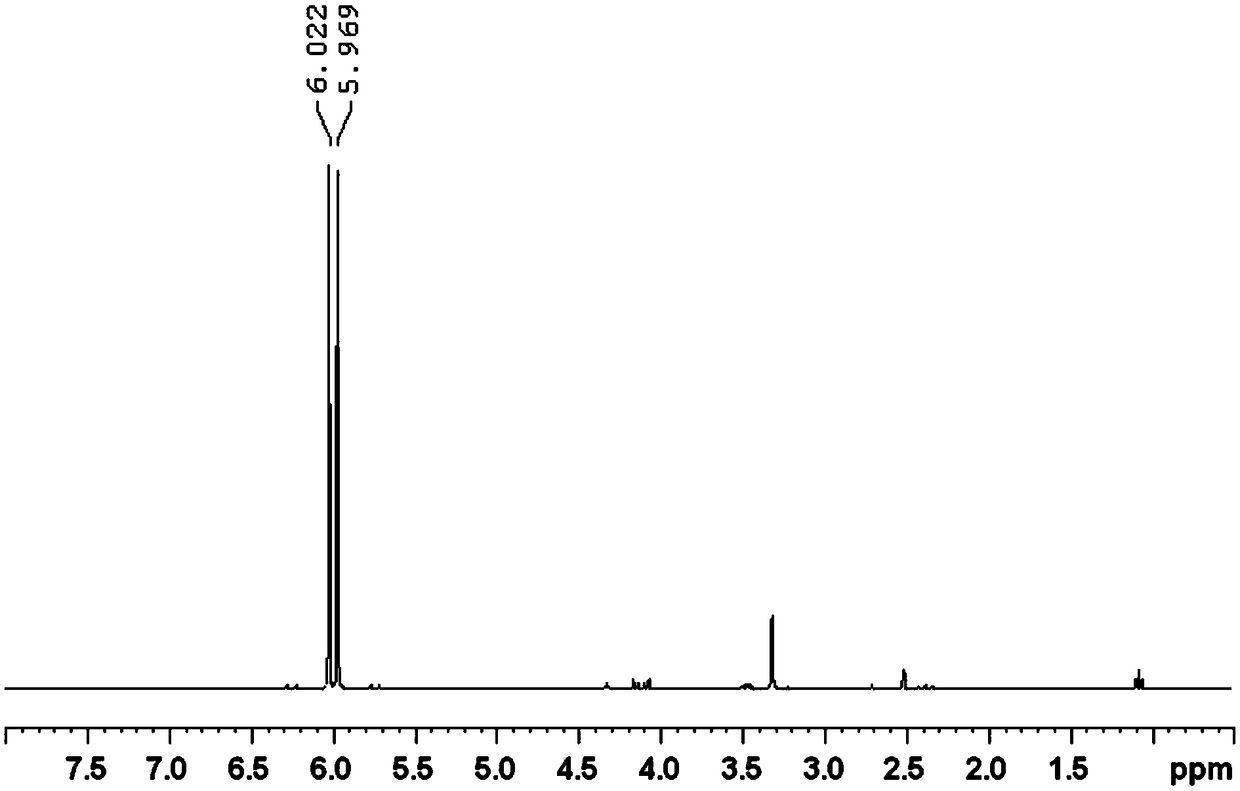

[0042] figure 1 The H NMR spectrum of 2-bromo-1,1-difluoroethylene prepared in Example 1 of the present invention;

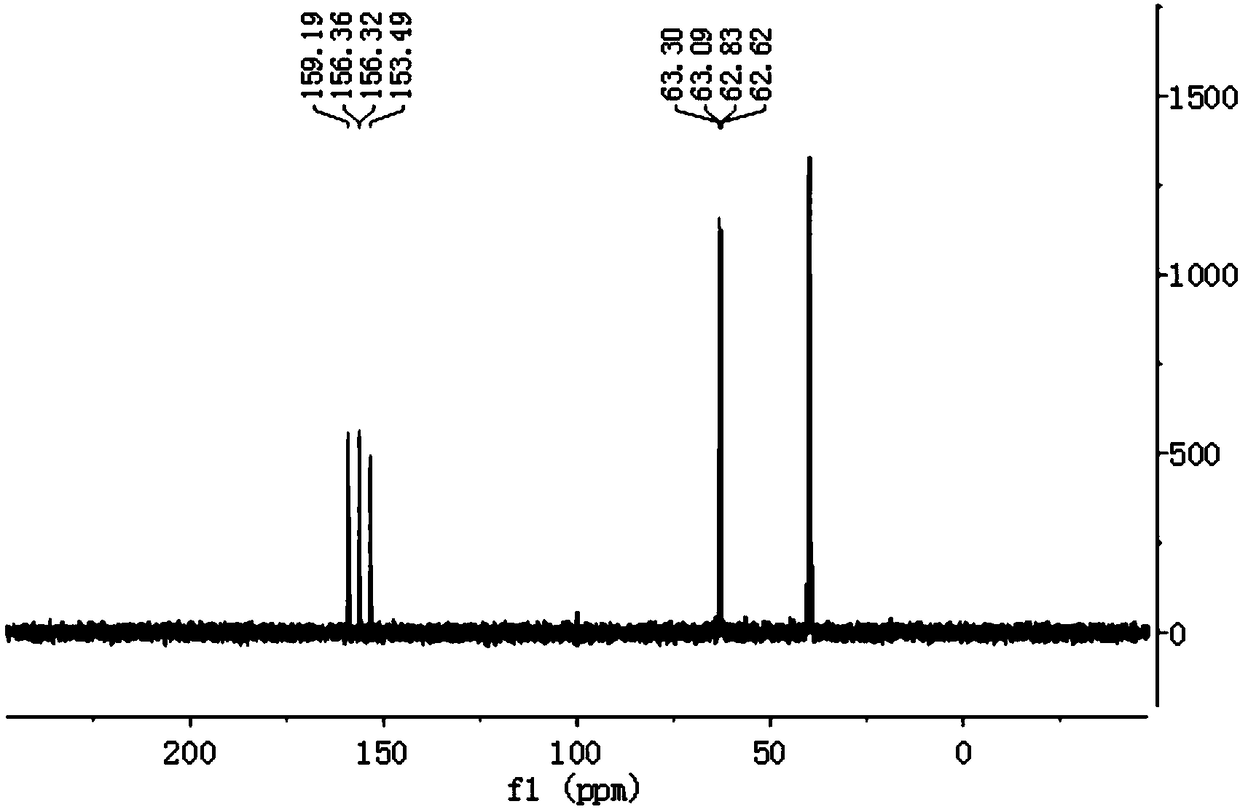

[0043] figure 2 The H NMR spectrum of 2-bromo-1,1-difluoroethylene prepared by the preparation method provided in Example 1 of the present invention; image 3 The carbon nuclear magnetic resonance spectrum of 2-bromo-1,1-difluoroethylene prepared by the preparati...

Embodiment 2

[0045] Put 5.2g of cuprous bromide, 320.4g of NBS, 23.4g of cesium carbonate and 500ml of carbon tetrachloride into the 2L stainless steel reaction kettle in sequence, cool down to the internal temperature of 0°C, fill with vinylidene fluoride to 1.8MPa, keep warm and react to pressure down to zero;

[0046] The reaction liquid in the kettle was discharged, and the product 2-bromo-1,1-difluoroethylene was collected by low-temperature rectification, 121.3g, with a yield of 70.7% and a purity of more than 99.5%;

[0047] The rectification raffinate was suction-filtered, and 110.7 g of cuprous bromide and succinimide were recovered.

[0048] As can be seen from the above examples, the present invention provides a preparation method of 2-bromo-1,1-difluoroethylene, comprising the following steps: under a copper catalyst, N-bromosuccinimide and vinylidene fluoride are In the presence of a base and an organic solvent, react to obtain 2-bromo-1,1-difluoroethylene. The invention ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com