A kind of mineralized hydrogel and its preparation method and application

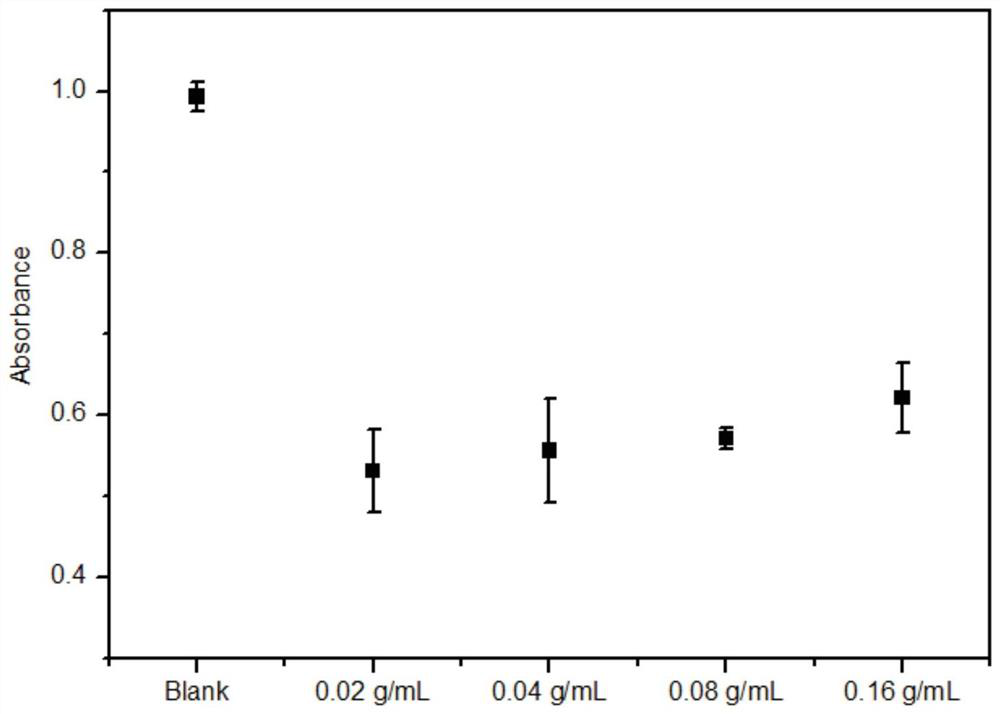

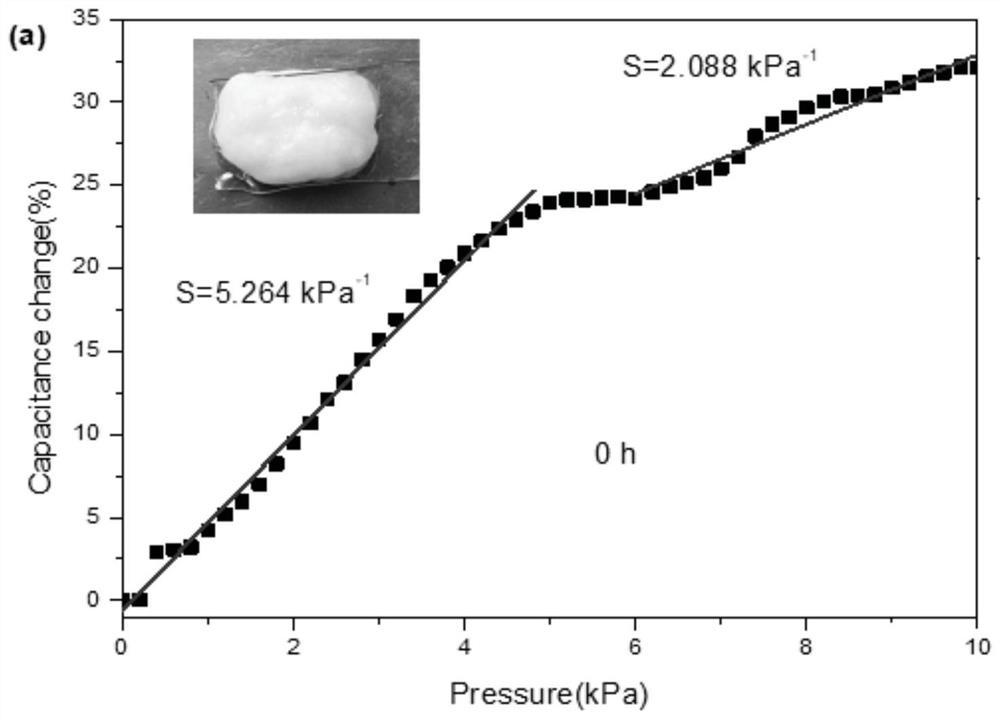

A technology of mineralized water and hydrogel, applied in the field of artificial skin, can solve the problem that artificial skin does not have both flexibility, antibacterial property and inductance, etc., and achieves the advantages of good adhesion, high pressure sensitivity and simple synthesis method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

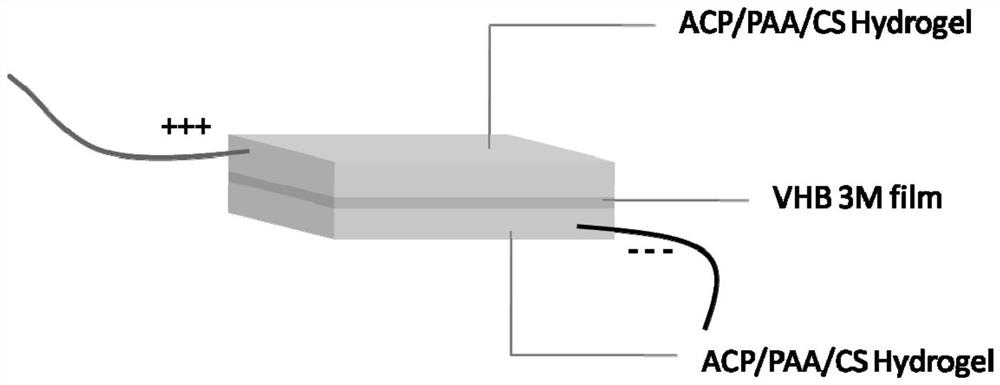

[0024] A method for preparing a multifunctional mineralized hydrogel, comprising the steps of:

[0025] (1) Dissolve 1.332g of anhydrous calcium chloride in 20mL of deionized water, add 3mL of polyacrylic acid (100,000 molecular weight) and stir at room temperature; In the acetic acid solution, weigh 3.5814g of disodium hydrogen phosphate dodecahydrate in 25mL deionized water at the same time, and mix the two after dissolving; (3) After magnetic stirring and mixing for 30min, slowly add the mixed solution of step (1) into step (2) In the solution, stir gently to obtain a white viscous mineralized (ACP / PAA / CS) hydrogel.

Embodiment 2

[0027] A method for preparing a multifunctional mineralized hydrogel, comprising the steps of:

[0028] (1) Dissolve 1.332g of anhydrous calcium chloride in 20mL of deionized water, add 3mL of polyacrylic acid (100,000 molecular weight) and stir at room temperature; In the acetic acid solution, weigh 3.5814g of disodium hydrogen phosphate dodecahydrate in 25mL deionized water at the same time, and mix the two after dissolving; (3) After magnetic stirring and mixing for 30min, slowly add the mixed solution of step (1) into step (2) In the solution, stir gently to obtain a white viscous mineralized (ACP / PAA / CS) hydrogel.

Embodiment 3

[0030] A method for preparing a multifunctional mineralized hydrogel, comprising the steps of:

[0031] (1) Dissolve 1.332g of anhydrous calcium chloride in 20mL of deionized water, add 2mL of polyacrylic acid (100,000 molecular weight) and stir at room temperature; (2) Weigh 0.061g of chitosan with medium molecular weight in 12mL of 0.1% In the acetic acid solution, weigh 3.5814g of disodium hydrogen phosphate dodecahydrate in 25mL deionized water at the same time, and mix the two after dissolving; (3) After magnetic stirring and mixing for 30min, slowly add the mixed solution of step (1) into step (2) In the solution, stir gently to obtain a white viscous mineralized (ACP / PAA / CS) hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com