Solar vacuum pipe

A technology of vacuum tubes and solar energy, applied in solar thermal energy, solar collectors, solar heating systems, etc., can solve the problems of low absorption rate and short service life, and achieve the effects of increased absorption rate, improved service life, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

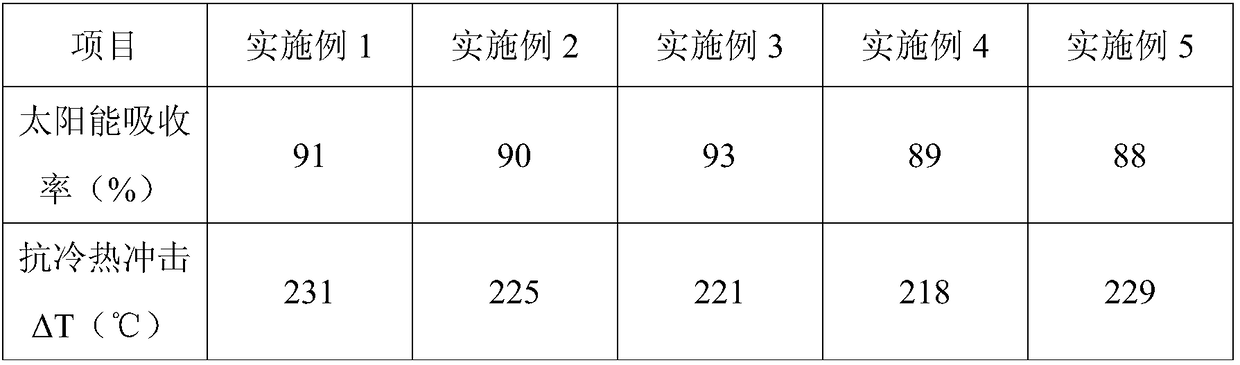

Examples

Embodiment 1

[0022] The raw material that is used to make composite absorbent layer in the present embodiment is as follows:

[0023] 40 parts vinyl resin;

[0024] 10 parts of aluminum silver powder (average particle size ≤ 50nm);

[0025] 20 parts isopropanol;

[0026] 1 part of mono-tert-butyl-p-cresol;

[0027] 1 part of aluminate coupling agent;

[0028] 1 part sodium dodecylbenzenesulfonate.

Embodiment 2

[0030] The raw material that is used to make composite absorbent layer in the present embodiment is as follows:

[0031] 55 parts of furfuryl alcohol modified urea-formaldehyde resins;

[0032] 15 parts of aluminum silver powder (average particle size ≤ 50nm);

[0033] 30 parts of butyl carbitol;

[0034] 3 parts pentaerythritol ester;

[0035] 3 parts of aluminate coupling agent;

[0036] 3 parts sodium dodecylbenzenesulfonate.

Embodiment 3

[0038] The raw material that is used to make composite absorbent layer in the present embodiment is as follows:

[0039] 42 parts vinyl resin;

[0040] 11 parts of aluminum silver powder (average particle size ≤ 50nm);

[0041] 23 parts of cyclohexanone;

[0042] 1 part of mono-tert-butyl-p-cresol;

[0043] 2 parts of aluminate coupling agent;

[0044] 1 part sodium dodecylbenzenesulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com