Flow-equalizing positive-pressure single-row solar/air energy evaporation heat collector

A solar energy and evaporator technology, which is applied to the field of equal-flow positive pressure single-row solar/air energy evaporative heat collectors, can solve the problems of increasing the total amount of solar energy absorption, uneven distribution of the evaporator airflow, and low performance, and achieves a reduction in Probability of frost to worsen heat transfer, reduce performance degradation, reduce blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

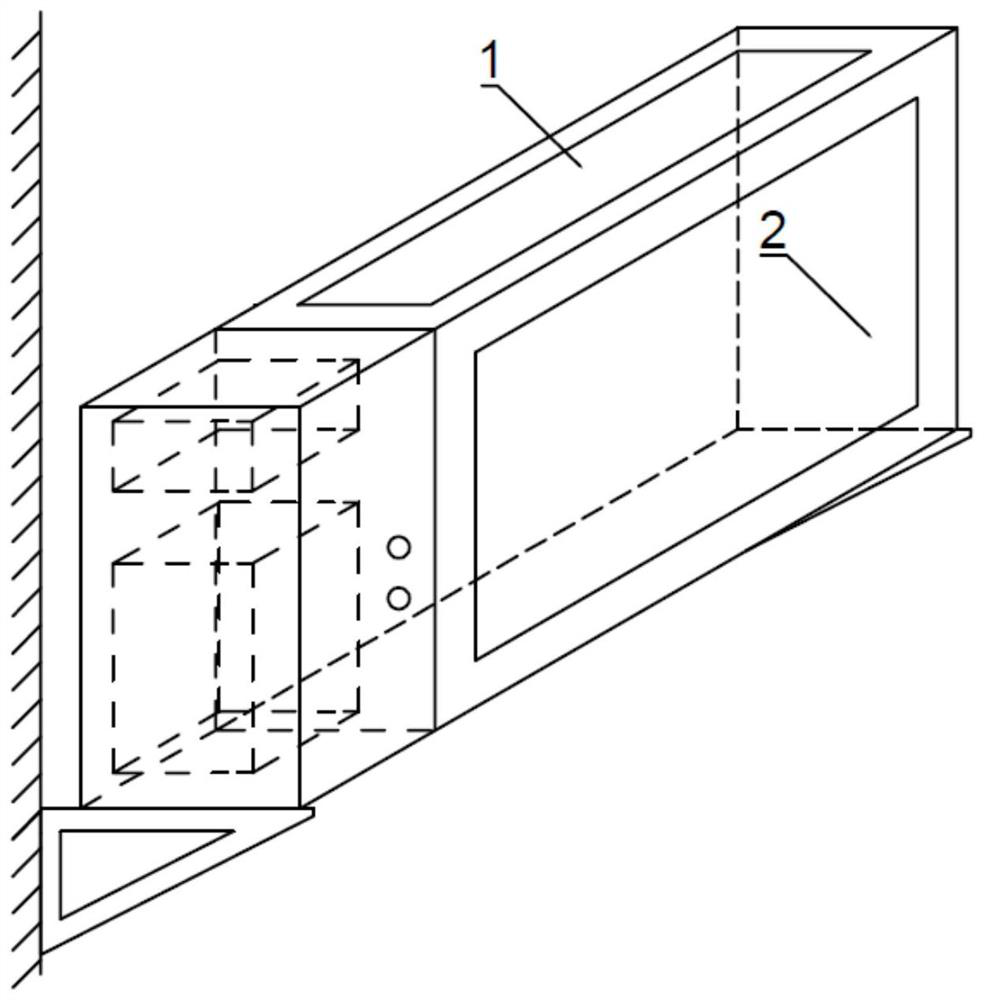

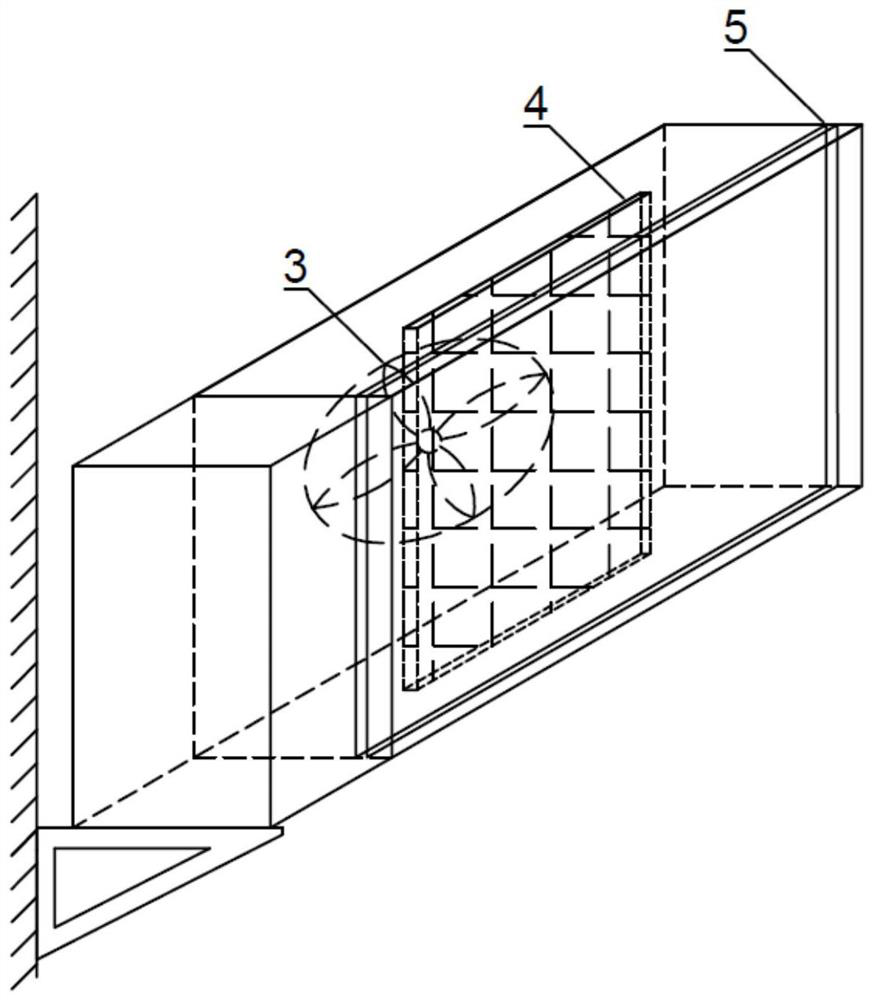

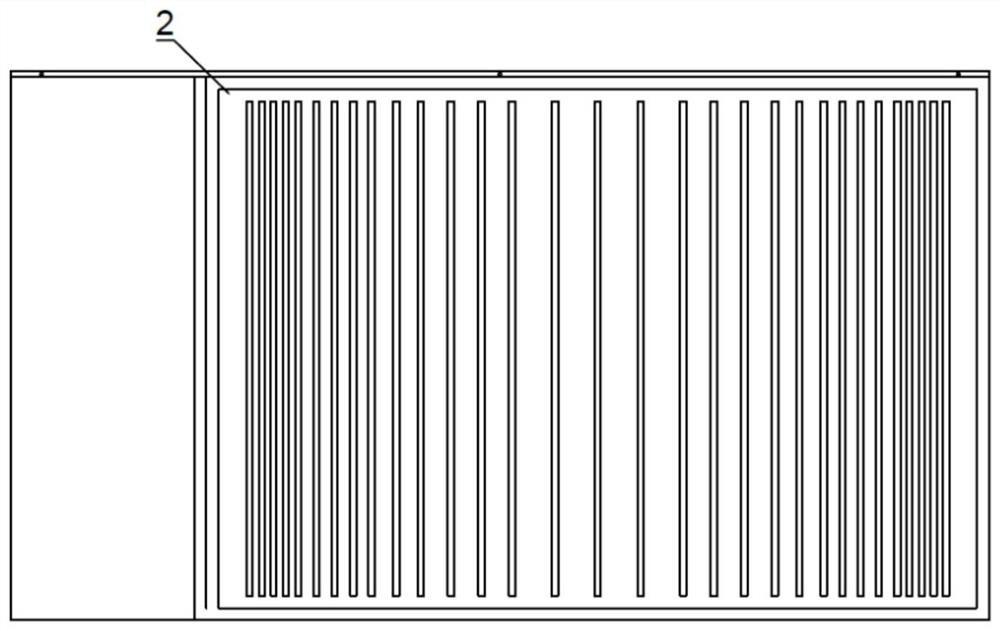

[0038] A single-row solar / air energy evaporative heat collector with equal flow and positive pressure. The evaporator fins are made of Al alloy with a thickness of 0.2mm. The chromium atomic layer is strongly magnetically condensed on the surface of the Al alloy fin by physical methods. The heat-absorbing heating film has a compact structure, an absorption rate of 0.93-0.97, an emissivity of 0.07-0.11, and stable physical and chemical properties. The micron-level thickness has little effect on the heat transfer coefficient of the aluminum alloy fins, which can reduce the loss of the heat transfer coefficient of the fins while increasing the solar radiation absorption.

[0039] The transparent casing of the unit is made of toughened glass, which has outstanding performance in physical and chemical stability, and is suitable for long-term, fully-loaded units. Open uneven ventilation holes on the front tempered glass, the specific operation is sparse on the central inspection sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com