A carbon film-assisted solar energy selective absorption film system and preparation method thereof

An absorbing film, solar energy technology, applied in solar thermal power generation, solar thermal devices, energy industry and other directions, can solve problems such as low emissivity, and achieve the effect of improving weather resistance and stability, long service life, low cost and high efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

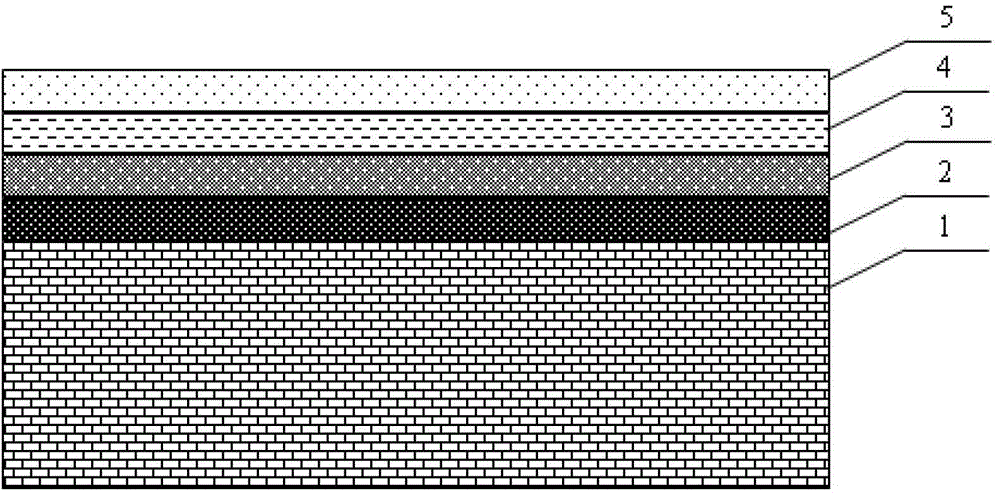

[0039] A carbon-film-assisted solar selective absorption film system 1 and a preparation method thereof.

[0040] The structure of this absorbing film is as attached figure 1 As shown, the thickness composition of each film layer is as follows:

[0041] Cu foil substrate / TiN x o y Thin film (50nm) / amorphous carbon thin film (100nm) / Si 3 N 4 Thin film (20nm) / SiO 2 Thin film (86nm).

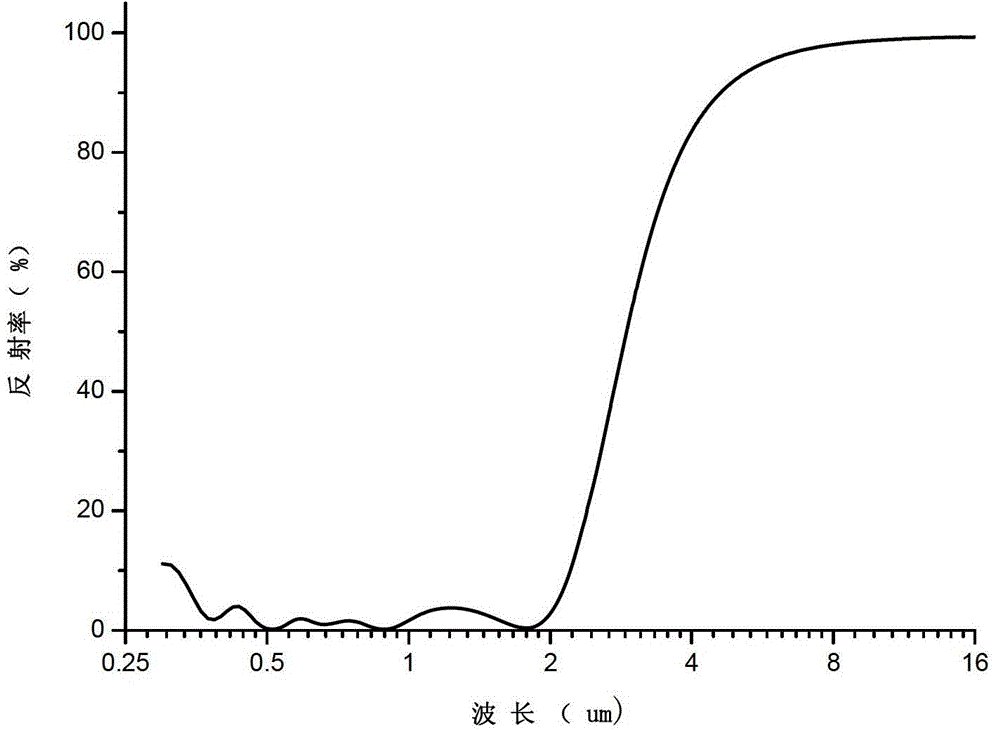

[0042] The reflection spectrum of the film system is attached figure 2 As shown, the technical indicators of the film system are as follows:

[0043] According to the national standard GB / T6424-2007 and GB / T 4271-2007, the absorption rate of the film system reaches 97.8%, and the emissivity is 3.2%.

[0044] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0045] First, using magnetron sputtering method, using Cu foil as the substrate, using TiN sintered accordin...

Embodiment 2

[0050] A carbon film-assisted solar selective absorption film system 2 and a preparation method thereof.

[0051] The structure of this absorbing film is as attached figure 1 As shown, the thickness composition of each film layer is as follows:

[0052] Ag-coated Cu foil substrate / TiN x o y Thin film (96nm) / amorphous carbon thin film (49nm) / Si 3 N 4 Thin film (25nm) / SiO 2 Thin film (89nm).

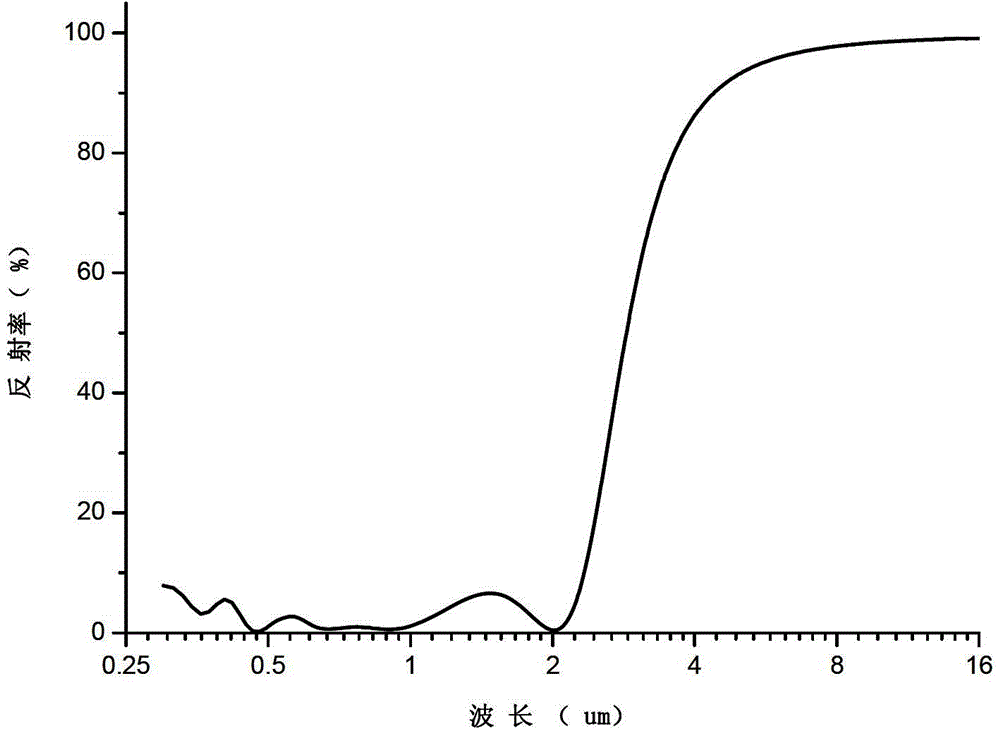

[0053] The reflection spectrum of the film system is attached image 3 As shown, the technical indicators of the film system are as follows:

[0054] According to the national standard GB / T6424-2007 and GB / T 4271-2007, the absorption rate of the film system reaches 98.0%, and the emissivity is 2.3%.

[0055] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0056] First, a layer of infrared highly reflective Ag thin film with a thickness of 100nm was plate...

Embodiment 3

[0063] A carbon film-assisted solar selective absorption film system 3 and a preparation method thereof.

[0064] The structure of this absorbing film is as attached figure 1 As shown, the thickness composition of each film layer is as follows:

[0065] Al foil substrate / TiN x o y Thin film (150nm) / Amorphous carbon thin film (20nm) / Si 3 N 4 Thin film (60nm) / SiO 2 Thin film (50nm).

[0066] The reflection spectrum of the film system is attached image 3 As shown, the technical indicators of the film system are as follows:

[0067] According to the national standard GB / T6424-2007 and GB / T 4271-2007, the absorption rate of the film system reaches 97.2%, and the emissivity is 3.6%.

[0068] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0069] First, using the magnetron sputtering method, using Al foil as the substrate, ceramic TiN as the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com