Non-quenched-tempered high-strength steel plate resistant to large heat input welding and manufacturing method thereof

A high-heat-input welding and high-strength steel plate technology, which is applied in the field of low-alloy steel, can solve problems such as poor toughness, and achieve stable performance, good economy, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A non-quenched and tempered high-strength steel plate resistant to large heat input welding provided by the present invention and its manufacturing method will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited in any form. All the improvements, modifications or similar replacements should be included in the protection scope of the present invention.

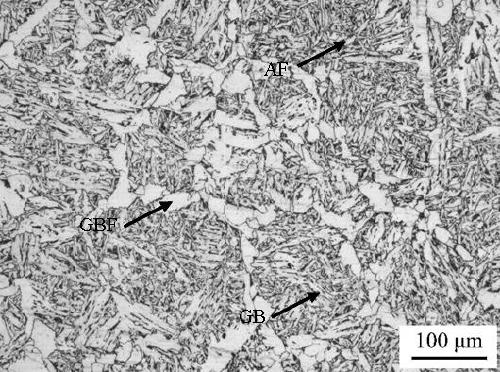

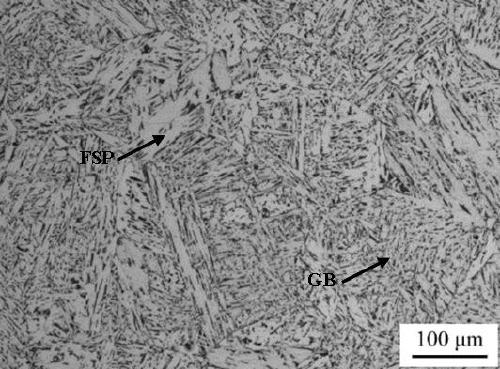

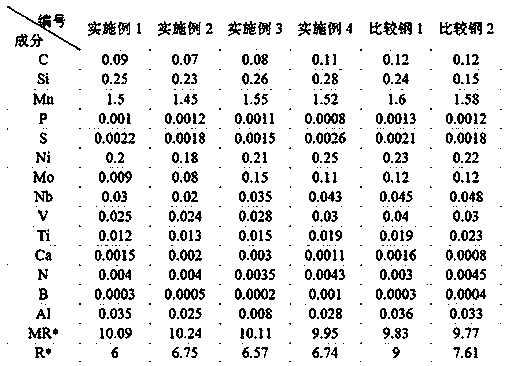

[0025] The invention provides a non-quenched and tempered high-strength steel plate resistant to large heat input welding. The chemical composition of the steel plate mainly includes Fe, C, Si, Mn, Ni, Nb, V, Ti, Ca, N, O and inevitable impurity, the element mass percentage content satisfies 9.92≤11.9-5.3C-0.91Mn-0.54Ni+0.46Si-0.73Nb+1.76V≤10.68 and 5.4≤C / Nb+Ti / N≤6.9. Exemplary chemical compositions are shown in Table 1, Examples 1-4.

[0026] Table 1 Example of chemical composition of non-quenched and tempered high-strength steel plates resistant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com