Electromagnetic shielding anti-radiation conductive fabric

An electromagnetic shielding and anti-radiation technology, applied in the field of textile fabrics, can solve the problems of genetic mutation, lack of anti-radiation, loss of antibacterial agents, etc., and achieve the effect of controlling electromagnetic interference in space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Another aspect of the present application relates to the preparation process of the above-mentioned fabric:

[0019] S1, cleaning the fabric body;

[0020] S2, magnetron sputtering Ag film;

[0021] S3, electroplating Ag film;

[0022] S4, electroless Cu plating film;

[0023] In S1, specifically, the cleaning of the fabric body is specifically cleaning the fabric body by ultrasonic method, and drying the fabric body after cleaning; in S2, specifically, the magnetron sputtering Ag film is specifically: placing the fabric body Put into the magnetron sputtering apparatus, vacuumize to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter Ag film, after the sputtering is completed, take out the fabric body, Nitrogen is used for purging; wherein, the thickness of the magnetron sputtered Ag film is preferably 1-2 μm; the m...

Embodiment 1

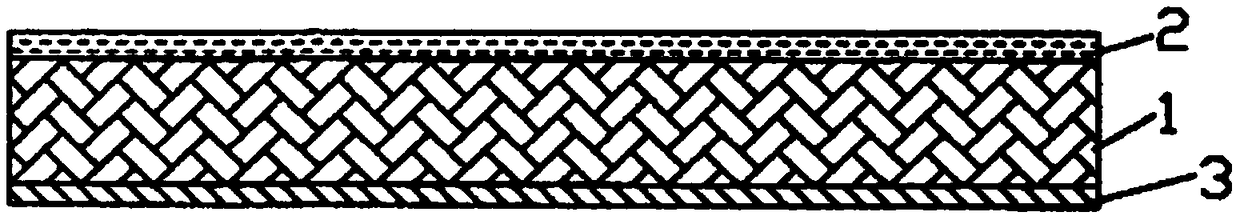

[0027] In this embodiment, an electromagnetic shielding fabric has a fabric body, and the fabric body is polyester fiber, wherein an Ag-Ag composite film and a Cu film are sequentially arranged on the surface of the fabric body from inside to outside.

[0028] The preparation process of the electromagnetic shielding fabric is:

[0029] S1. Clean the fabric body

[0030] The fabric body is cleaned by ultrasonic method, and after cleaning, the fabric body is dried;

[0031] S2, magnetron sputtering Ag film

[0032] Put the fabric body into the magnetron sputtering apparatus, and evacuate to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter Ag film, after the sputtering is completed, take out the fabric body, Nitrogen purging is used;

[0033] Wherein, the thickness of described magnetron sputtering Ag film is preferably 1 ...

Embodiment 2

[0046] In this embodiment, an electromagnetic shielding fabric has a fabric body, and the fabric body is polyester fiber, wherein an Ag-Ag composite film and a Cu film are sequentially arranged on the surface of the fabric body from inside to outside.

[0047] The preparation process of the electromagnetic shielding fabric is:

[0048] S1. Clean the fabric body

[0049] The fabric body is cleaned by ultrasonic method, and after cleaning, the fabric body is dried;

[0050] S2, magnetron sputtering Ag film

[0051] Put the fabric body into the magnetron sputtering apparatus, and evacuate to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter Ag film, after the sputtering is completed, take out the fabric body, Nitrogen purging is used;

[0052] Wherein, the thickness of described magnetron sputtering Ag film is preferably 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com