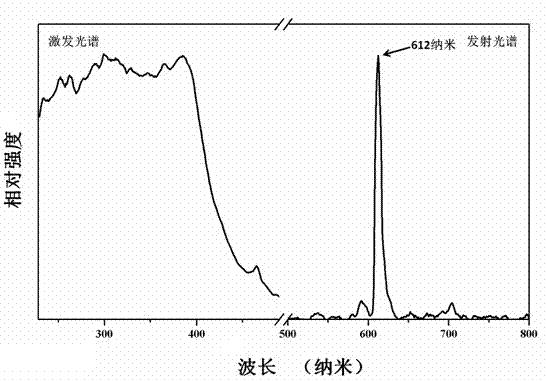

Light-conversion EVA (Ethylene Vinyl-Acetate Copolymer) adhesive film for solar battery and preparation method thereof

A solar cell and film technology, applied in circuits, adhesives, photovoltaic power generation, etc., can solve problems such as reducing power generation efficiency, accelerating the aging of component materials, heating solar cell components, etc., to achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

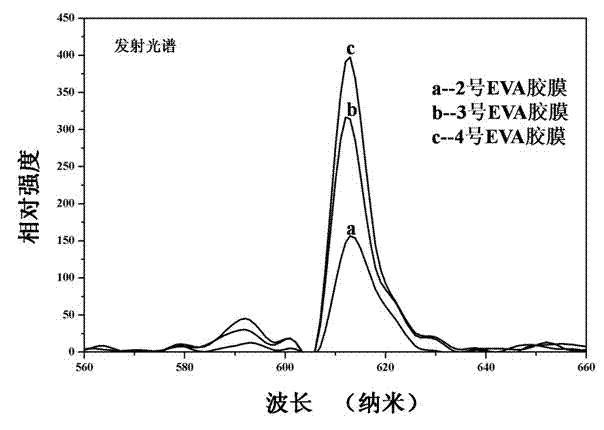

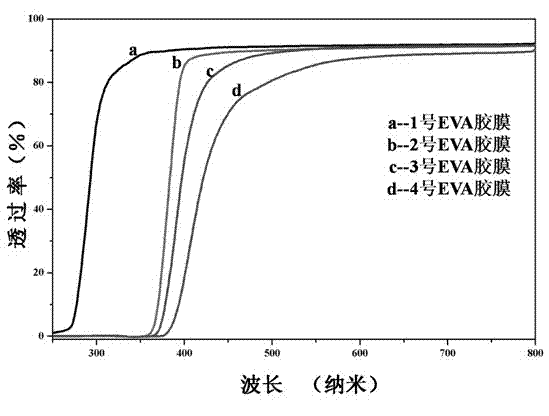

Embodiment 1

[0037] In terms of parts by weight, 0.1 part of luminescent complex, 0.2 part of antioxidant, 1.5 part of crosslinking agent and 0.1 part of accelerator are added to 100 parts of ethylene-vinyl acetate copolymer (EVA) with a VA content of 33%.

[0038] The luminescent complex is a rare earth europium complex, the crosslinking agent is dibenzoyl peroxide, and the antioxidant is 1, 3, 5-tris(4-tert-butyl-3-hydroxy-2, 6-dimethylbenzene Methyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite complex, The accelerator is triallyl triisocyanate.

[0039] (1) First mix the above raw materials evenly;

[0040] (2) Pour the mixture obtained in step (1) into a twin-screw extrusion granulator for mixing and granulation. The twin-screw extruder is divided into three sections, namely, the entrance section, the middle section and the exit section. : 81~84℃, 85~90℃, 84~86℃;

[0041] (3) The granulated particles can be passed through the film-forming system to ...

Embodiment 2

[0043] In terms of parts by weight, 1 part of luminescent complex, 0.2 part of antioxidant, 1.5 part of crosslinking agent and 0.1 part of accelerator are added to 100 parts of ethylene-vinyl acetate copolymer (EVA) with a VA content of 33%.

[0044] The luminescent complex is a rare earth europium complex, the crosslinking agent is dibenzoyl peroxide, and the antioxidant is 1, 3, 5-tris(4-tert-butyl-3-hydroxy-2, 6-dimethylbenzene Methyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite complex, The accelerator is triallyl triisocyanate.

[0045] (1) First mix the above raw materials evenly;

[0046] (2) Pour the mixture obtained in step (1) into a twin-screw extrusion granulator for mixing and granulation. The twin-screw extruder is divided into three sections, namely, the entrance section, the middle section and the exit section. : 81~84℃, 85~90℃, 84~86℃;

[0047] (3) The granulated particles can be passed through the film-forming system to ob...

Embodiment 3

[0049] In parts by weight, 2 parts of luminescent complex, 0.2 part of antioxidant, 1.5 part of crosslinking agent and 0.1 part of accelerator are added to 100 parts of ethylene-vinyl acetate copolymer (EVA) with VA content of 33%.

[0050] The luminescent complex is a rare earth europium complex, the crosslinking agent is dibenzoyl peroxide, and the antioxidant is 1, 3, 5-tris(4-tert-butyl-3-hydroxy-2, 6-dimethylbenzene Methyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite complex, The accelerator is triallyl triisocyanate.

[0051] (1) First mix the above raw materials evenly;

[0052] (2) Pour the mixture obtained in step (1) into a twin-screw extrusion granulator for mixing and granulation. The twin-screw extruder is divided into three sections, namely, the entrance section, the middle section and the exit section. : 81~84℃, 85~90℃, 84~86℃;

[0053] (3) The granulated particles can be passed through the film-forming system to obtain the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com