Metal hose flow characteristic testing device and method

A technology of metal hose and flow characteristics, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. Influence and affect the accuracy of test results, etc., to achieve the effect of controllable test conditions, simple composition, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

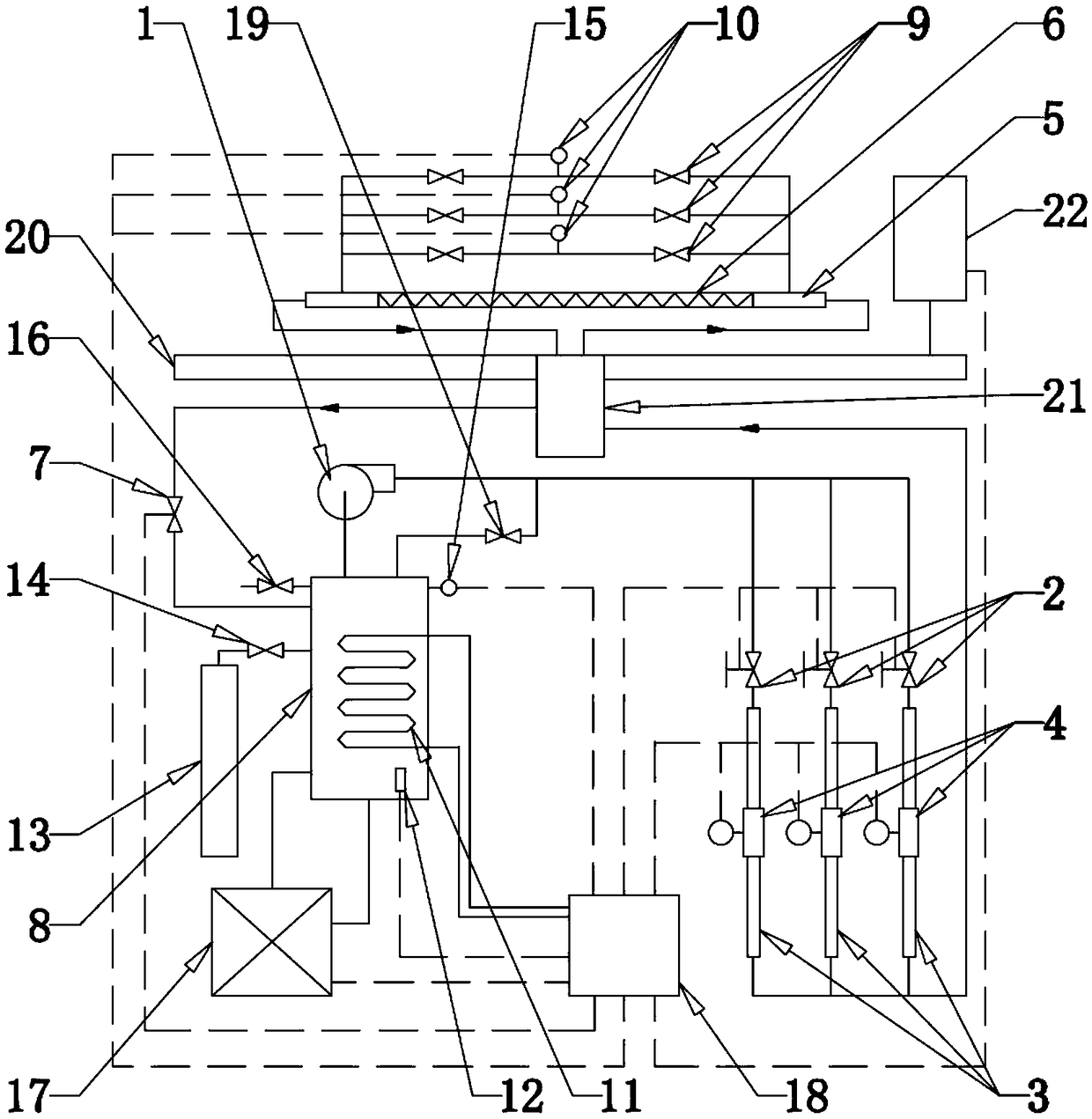

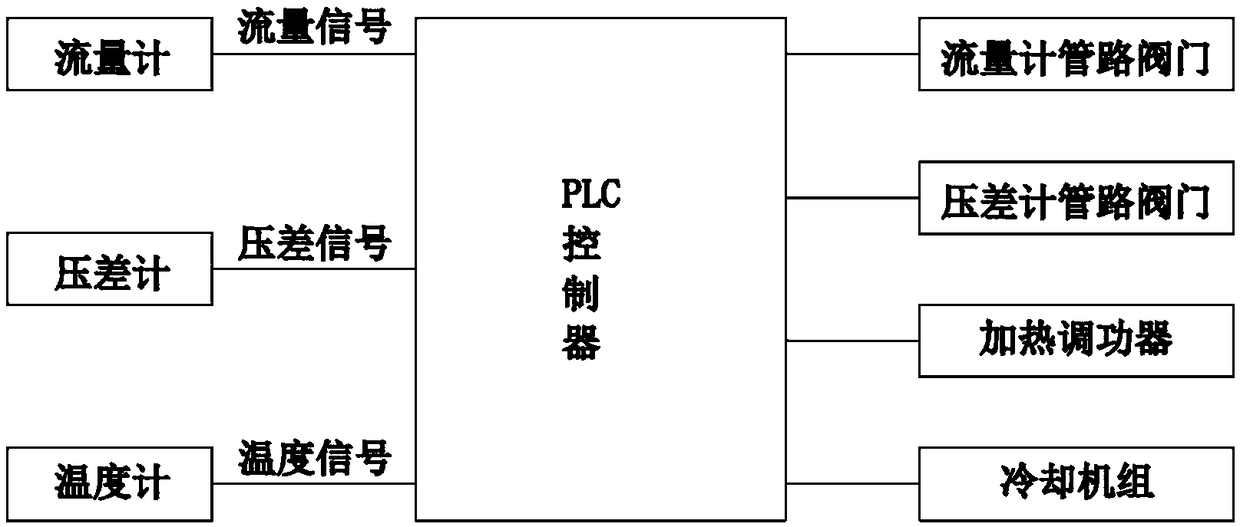

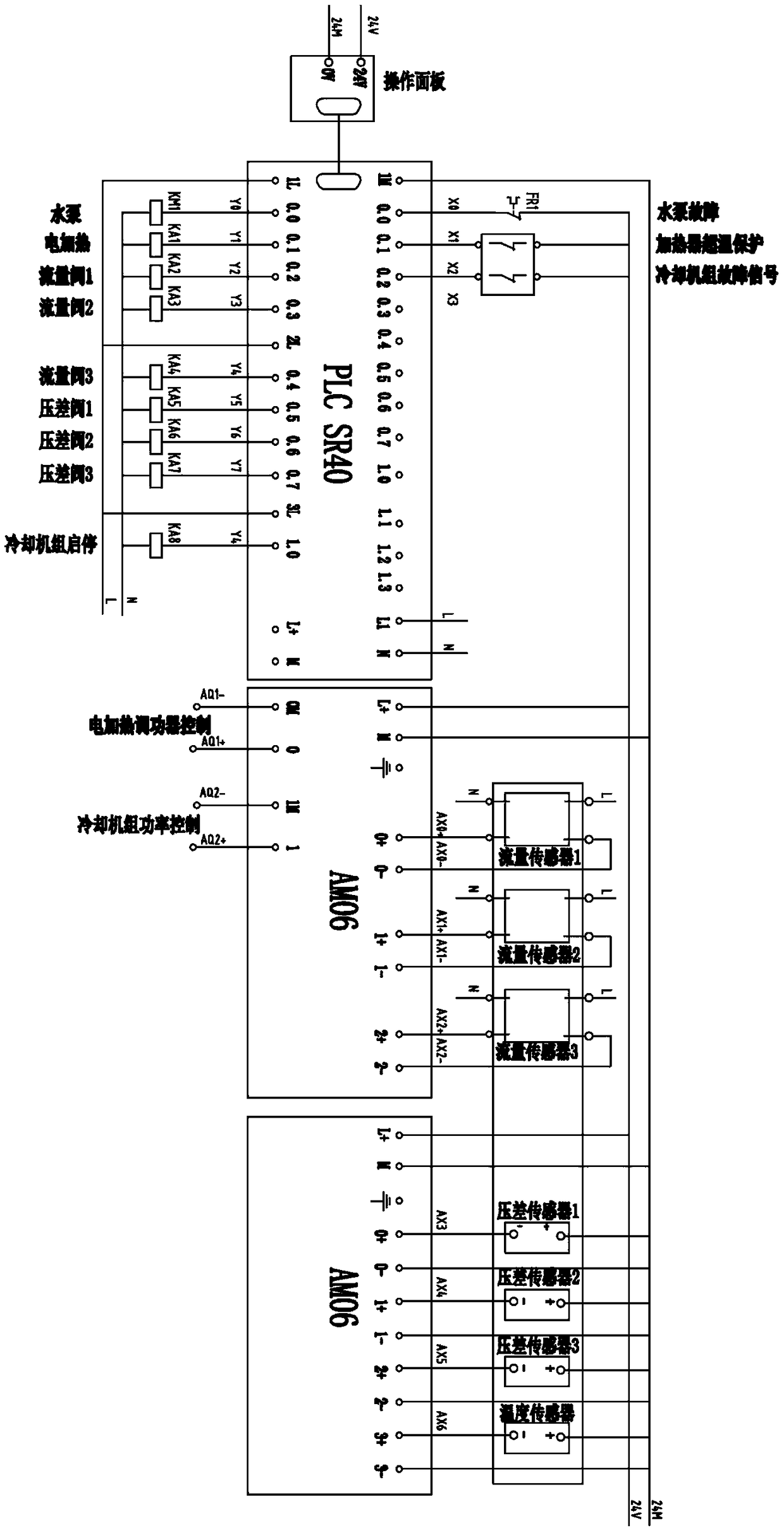

[0056] The metal hose flow characteristic test equipment of the present embodiment constitutes as figure 1 As shown, the two ends of the metal hose 6 to be tested are respectively connected with the front and rear pressure difference steady flow tubes 5, wherein the length of the front pressure difference steady flow tube is 10-12 times the diameter of the metal hose 6 to be tested, and the rear pressure difference The length of the differential steady flow tube is 5-8 times of the diameter of the metal hose 6 to be tested. The front and rear differential pressure stabilizing tubes 5 are respectively connected to two ends of three parallel differential pressure test pipelines with different diameters. Each differential pressure test pipeline is respectively connected in series with a differential pressure control valve 9 and a differential pressure sensor 10 . The rear differential pressure stabilizing pipe 5 is connected to the return port of the stabilizing water tank 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com