Laser ultrasonic transmission type time-delay detection method for internal defects of material

An internal defect, laser ultrasonic technology, used in the analysis of materials, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of low signal-to-noise ratio of detection signals, low ultrasonic amplitude, and ultrasonic amplitude fluctuations. , to achieve the effect of accurate detection results, reduced interference factors, accurate positioning and quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

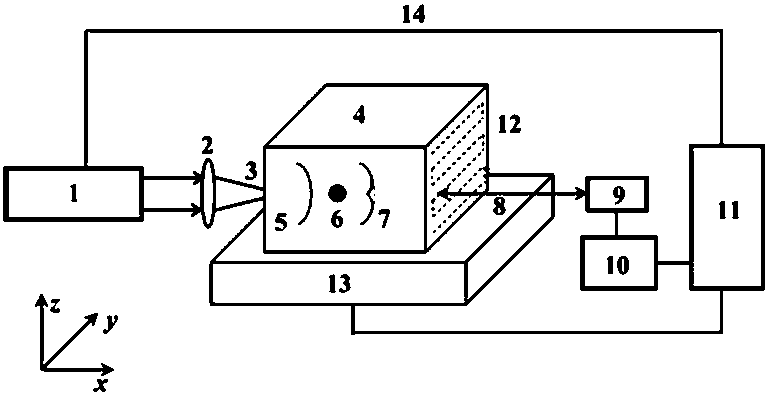

[0047] This embodiment is used to detect internal defects of aluminum alloy samples.

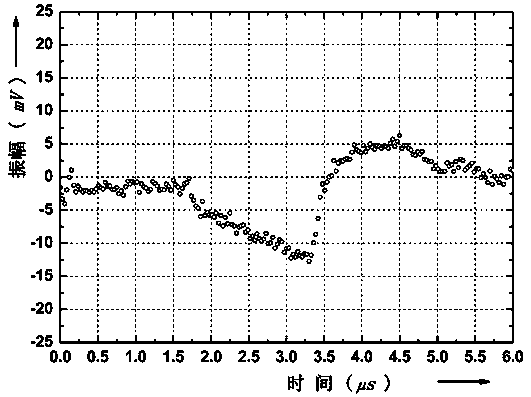

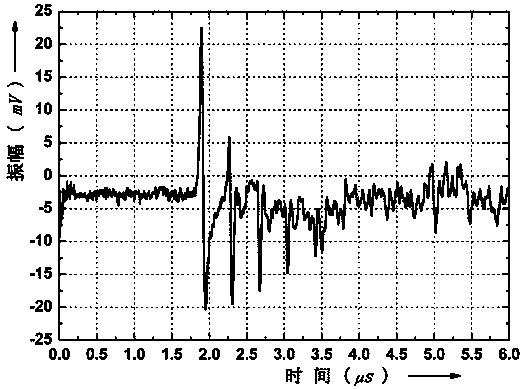

[0048] Nd: YAG laser excites a pulsed laser with a wavelength of 1064 nm, a pulse width of 7ns, a repetition frequency of 10Hz, and a single pulse energy of 20mJ. After passing through a convex lens, it is focused into a circular light source with a diameter of 1 mm and irradiated on the surface of the aluminum alloy sample to excite ultrasonic waves It propagates to the inside of the sample along the direction perpendicular to the sample surface. At the center position on the other side of the sample surface irradiated by the circular light source, a continuous laser with a wavelength of 532nm and a power of 200 mW was irradiated by a laser interferometer to perform non-contact detection of the ultrasonic signal. The trigger signal from the excitation laser and the ultrasonic signal detected by the laser interferometer are transmitted to the industrial computer for waveform display and process...

Embodiment 2

[0059] This embodiment is used to detect internal defects of non-metallic material samples. The non-metallic material can be silicon, opaque glass, ceramic, plastic, etc.

[0060] The implementation of this embodiment is basically the same as that of embodiment 1, the main difference is that the circular light source 3 directly irradiates the surface of the sample, and the optical power density of the circular light source 3 is less than the light damage threshold of the non-metallic sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com