Silicon-based tunable laser

A tunable laser, silicon-based technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of slow progress of core device lasers, complex tunable laser fabrication, and hinder laser on-chip integration, achieving low loss and simple structure. , Improve the effect of wavelength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments are part of the embodiments of the present application, not all of them.

[0023] In this application, when it is described that a specific component is located between a first component and a second component, there may or may not be an intermediate component between the specific component and the first component or the second component; When a specific component is connected to other components, the specific component may be directly connected to the other component without an intermediate component, or may not be directly connected to the other component but has an intermediate component.

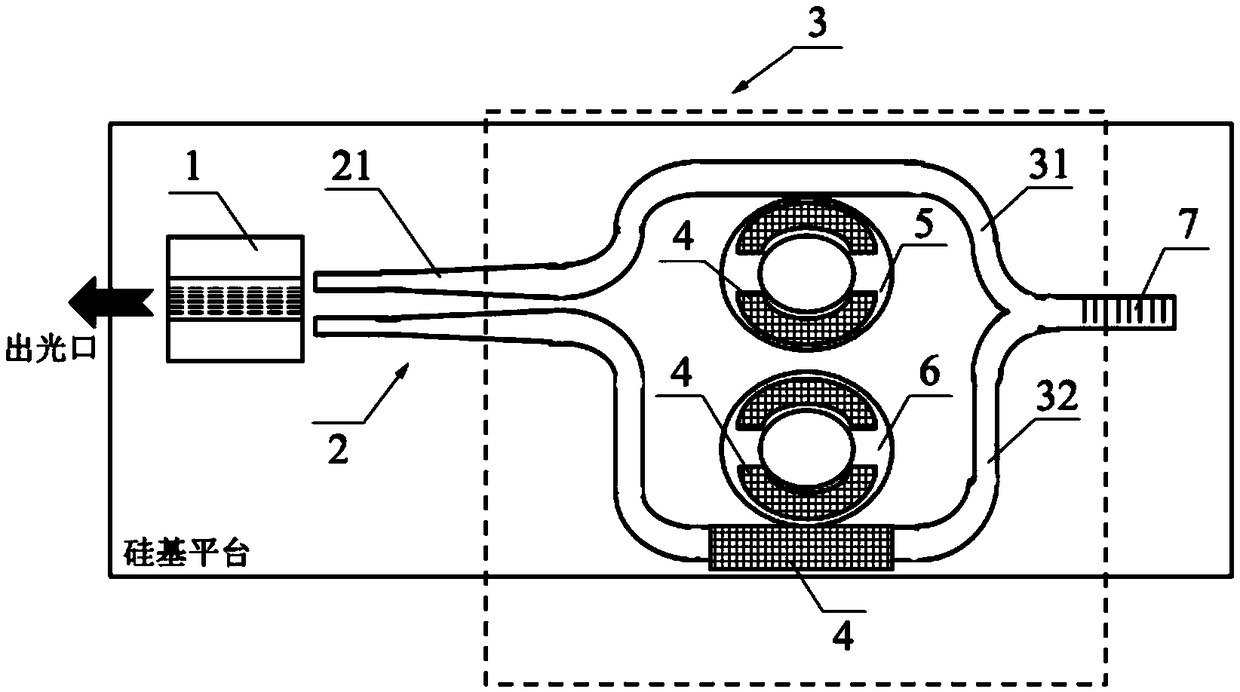

[0024] see figure 1 as shown, figure 1 is a layout diagram of a silicon-based tunable laser, which includes a semiconductor amplifier 1, a mode sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com