Biodegradable photopolymerizable polymer composite material by layered manufacturing and its application

A technology of laminated manufacturing and composite materials, which is applied in the field of biodegradable photopolymerized polymer composite materials, can solve the problems of difficult adjustment of hardness and elasticity, difficult prediction of degradation characteristics, and difficulty in forming materials, so as to reduce the inconvenience of use and Effect of design constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

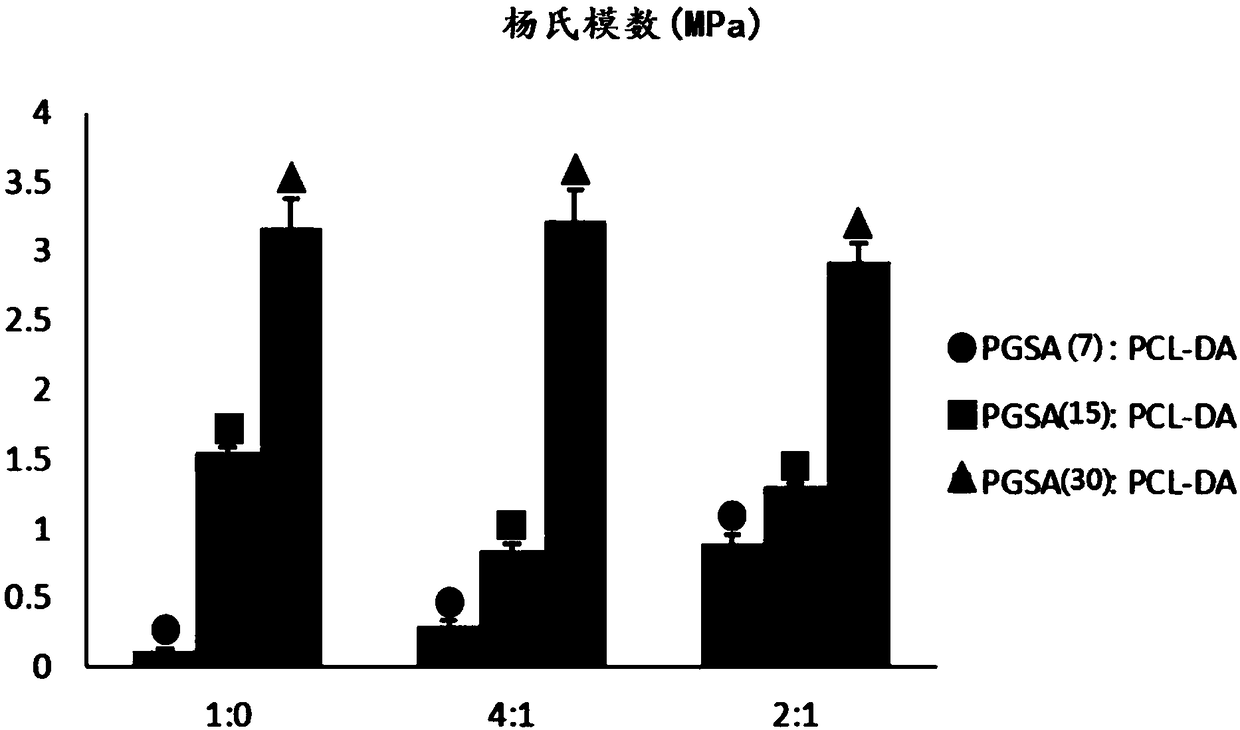

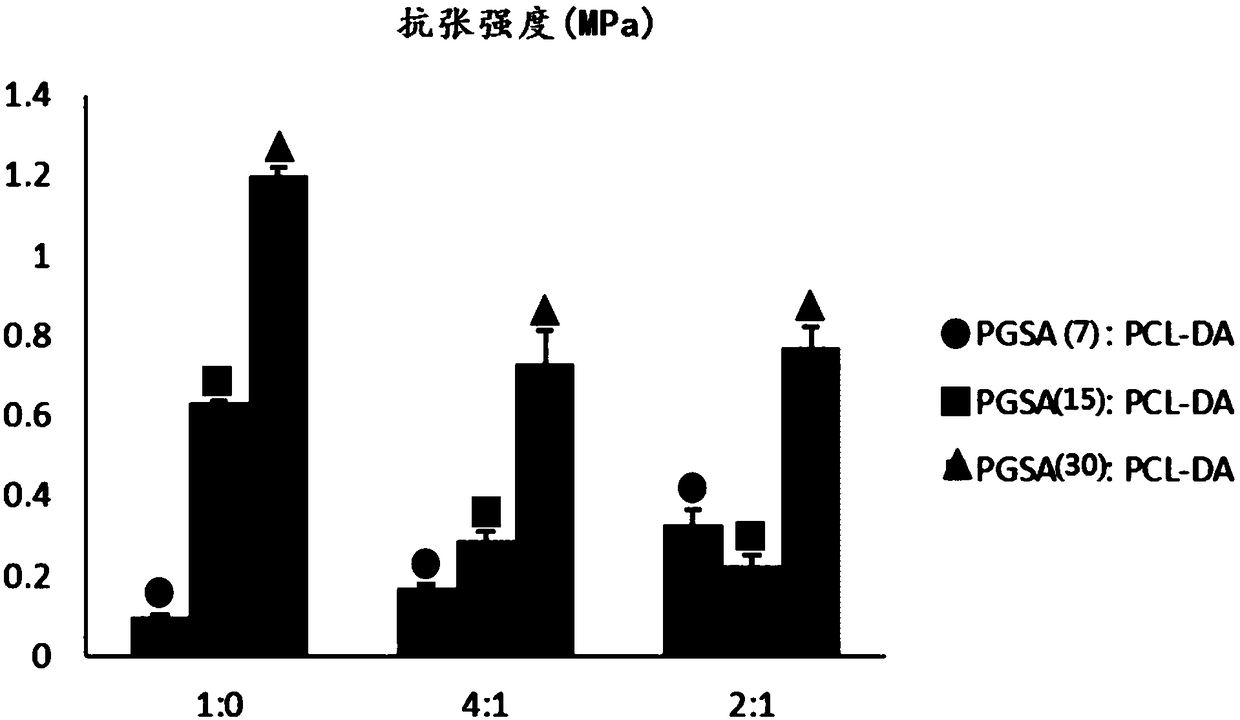

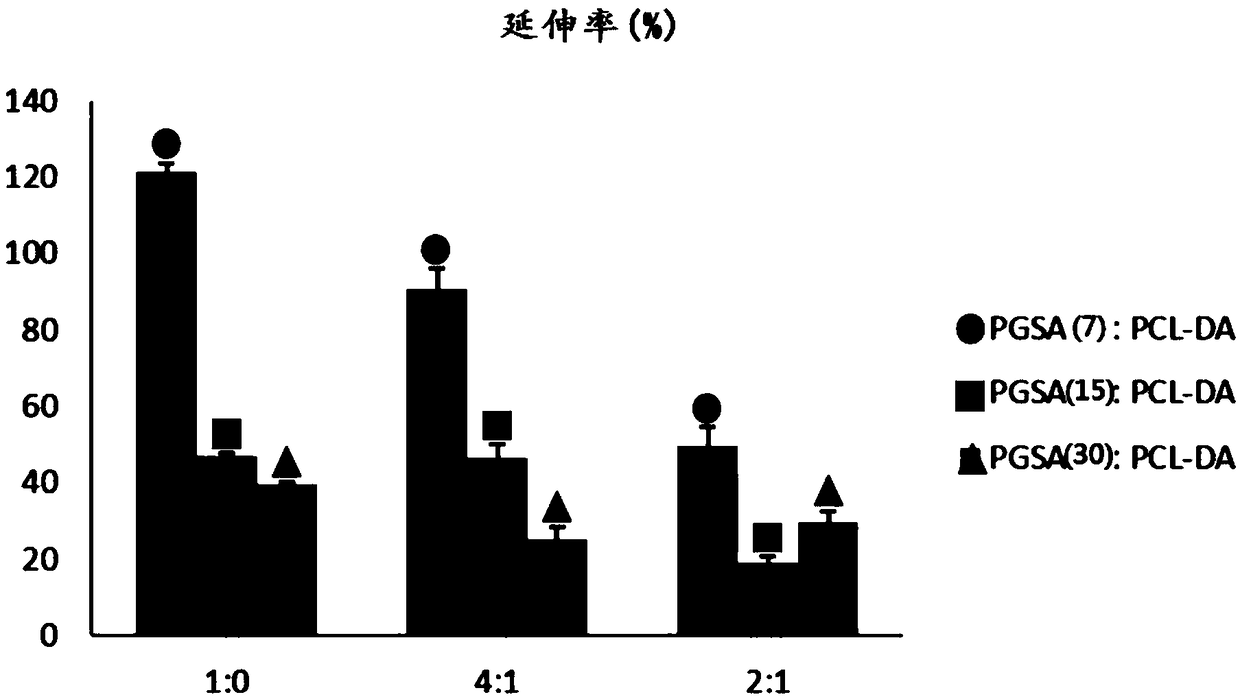

[0028] A biodegradable photopolymerizable polymer composite material that can be manufactured by lamination, which includes PGSA (Poly (glycerol sebacate acrylate)), a photoinitiator, and a photoinitiator selected from PCL-DA (Polycaprolactone-diacrylate), PEG-DA (Polyethyleneglycol -diacrylate), the degree of acrylation of the PGSA is preferably between 5% and 60%, more preferably between 7% and 30%.

[0029] The PGSA, PCL-DA and PEG-DA used in the present invention are all materials with biocompatibility and good degradability, and the present invention selects PCL-DA and PEG-DA containing acrylic acid group (Diarcylate, DA) to make PGSA, After PCL-DA and PEG-DA are laminated and formed by light, a better cross-linked network can be formed between the material molecules.

[0030] The photoinitiator used in the present invention preferably also has biocompatibility, which is mainly a component that can make the material photocurable when the present invention is manufactured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com