Polyester and preparation method thereof as well as hydrolysis-resistant polyester film and preparation method and application thereof

A polyester film, polyester technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as reducing water vapor permeability, increasing production costs, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

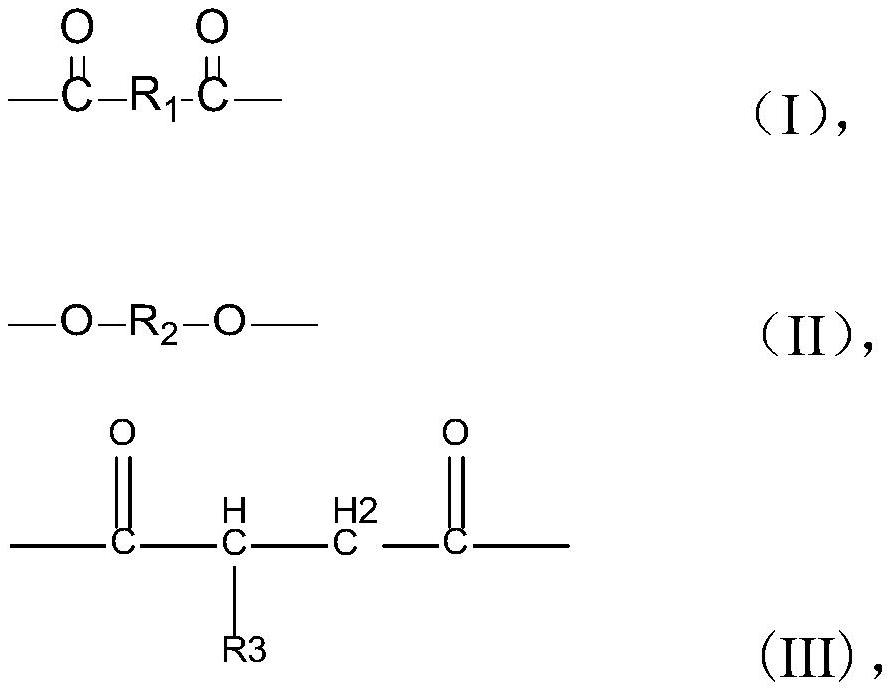

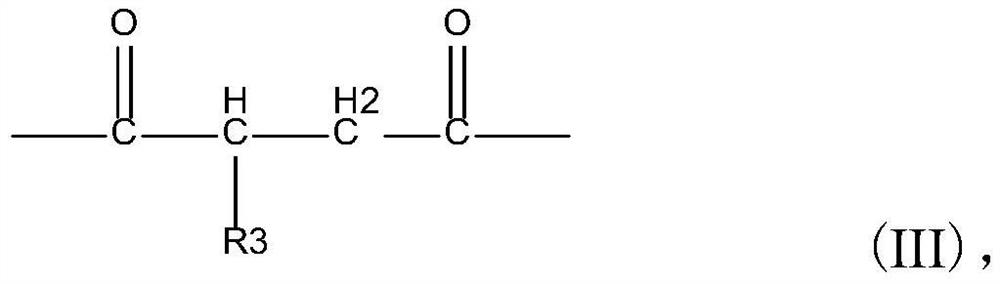

Method used

Image

Examples

Embodiment 1

[0051] 600g of terephthalic acid, 300g of ethylene glycol and 0.27g of ethylene glycol antimony were mixed uniformly, added to the reaction kettle for esterification reaction, the reaction conditions were temperature 255°C, pressure 260kPa, time 2h; 4.5g of maleic anhydride grafted polyethylene (the quality of maleic anhydride accounted for 0.5wt% of the mass of maleic anhydride grafted polyethylene) was added in the reaction kettle to carry out polycondensation reaction, the temperature was 270°C, and the pressure was 100Pa; After the end, nitrogen is passed through, the material is discharged, and after dicing, the hydrolysis-resistant polyester with an intrinsic viscosity of 0.72 dL / g is obtained; the obtained polyester is subjected to an extrusion casting process and heat treatment at 120° C. for 5 minutes to obtain a hydrolysis-resistant polyester film.

[0052] The obtained polyester film had a breaking elongation retention rate of 50% after 48 hours in an environment wit...

Embodiment 2

[0055] Mix 700g of 2,6-naphthalenedicarboxylic acid, 295g of 1,3-propanediol and 0.02g of tetrabutyl titanate evenly, and add them to the reaction kettle to carry out esterification reaction. The reaction conditions are that the temperature is 240°C, the pressure is 230kPa, and the time is 1.6h. The reactor is down to normal pressure, and 29.5g maleic anhydride grafted styrene-ethylene-butylene-styrene copolymer (the maleic anhydride quality accounts for maleic anhydride grafted styrene-ethylene-butylene-benzene) 1wt% of the mass of the ethylene copolymer) was added to the reaction kettle to carry out the polycondensation reaction, the temperature was 262°C, and the pressure was 20Pa; after the reaction, nitrogen was passed through, the material was discharged, and the intrinsic viscosity was 0.66dL / g after dicing. ester; hydrolysis-resistant polyester film is prepared by extruding and calendering the obtained polyester and heat treatment at 80° C. for 60 minutes.

[0056] The...

Embodiment 3

[0058] 500g 4,4'-biphenyl dicarboxylic acid, 310g 1,4-cyclohexanedimethanol and 0.08g aluminum acetate were mixed uniformly, added to the reaction kettle to carry out esterification reaction, the reaction conditions were temperature 250°C, pressure 290kPa, Time 2.4h; the reaction kettle was reduced to normal pressure, and 48g of maleic anhydride grafted polypropylene (the mass of maleic anhydride accounted for 0.2wt% of the mass of maleic anhydride grafted polypropylene) was added to the reaction kettle to carry out polycondensation reaction, The temperature was 275°C, and the pressure was 180Pa; after the reaction, nitrogen was passed through, the material was discharged, and after dicing, a hydrolysis-resistant polyester with an intrinsic viscosity of 0.81 dL / g was obtained; A hydrolysis-resistant polyester film was obtained.

[0059] The obtained polyester film had a breaking elongation retention rate of 40% after 48 hours in an environment with a temperature of 121° C. and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com