A nanogel-based smart switch membrane and its preparation method

A nano-gel and smart switch technology, applied in the field of separation membrane, can solve the problems of poor response switching coefficient, etc., and achieve the effect of improving the response switching coefficient, excellent cycle response stability, excellent temperature and pH response switching coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this example, the preparation method of nanogel / polyethersulfone membrane with temperature and pH stimulus response is as follows:

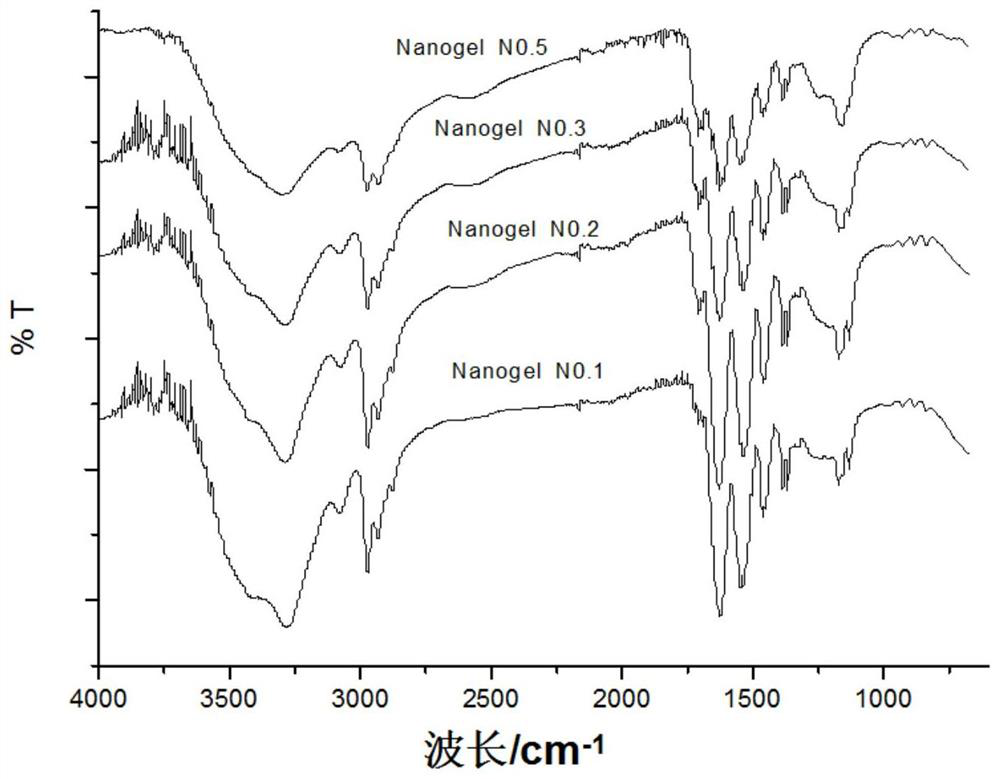

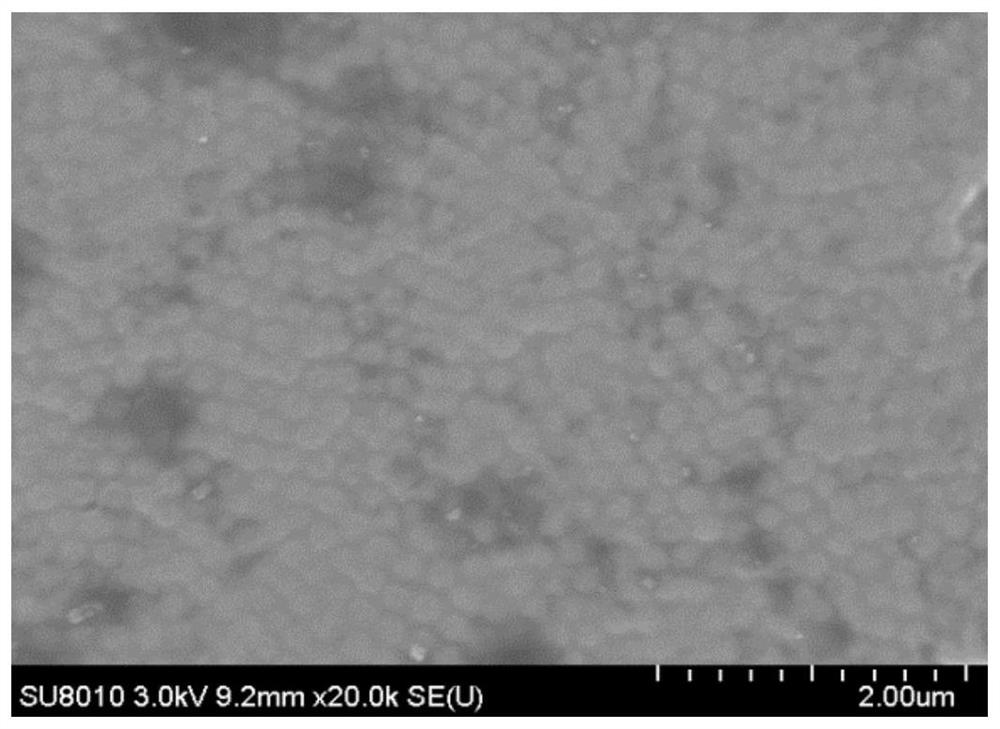

[0047] (1) Synthesis of P(NIPAM-co-MAA) nanogels with temperature- and pH-responsive behavior: NIPAM monomer, MAA monomer, MBA crosslinker, APS initiator, and SDS surfactant were added to deionized water , under the protection of nitrogen, react at 70°C for 3 hours to obtain P(NIPAM-co-MAA) nanogel suspension.

[0048] The concentration of the reactant total monomer (NIPAM and MAA) is 0.07mol L -1 , the feed molar ratio of MAA to NIPAM is 2:8; the feed molar ratio of MBA and APS to the total monomer (NIPAM and MAA) is 5% and 2%, and the concentration of SDS in water is 0.104mmol L -1 .

[0049] (2) the nanogel suspension of step (1) is thoroughly purified with the centrifugation of 8000-10000r / min gained nanogel, then repeats to be dispersed in water 5 times to at least remove residual unreacted component; The purified nanogel was fr...

Embodiment 2

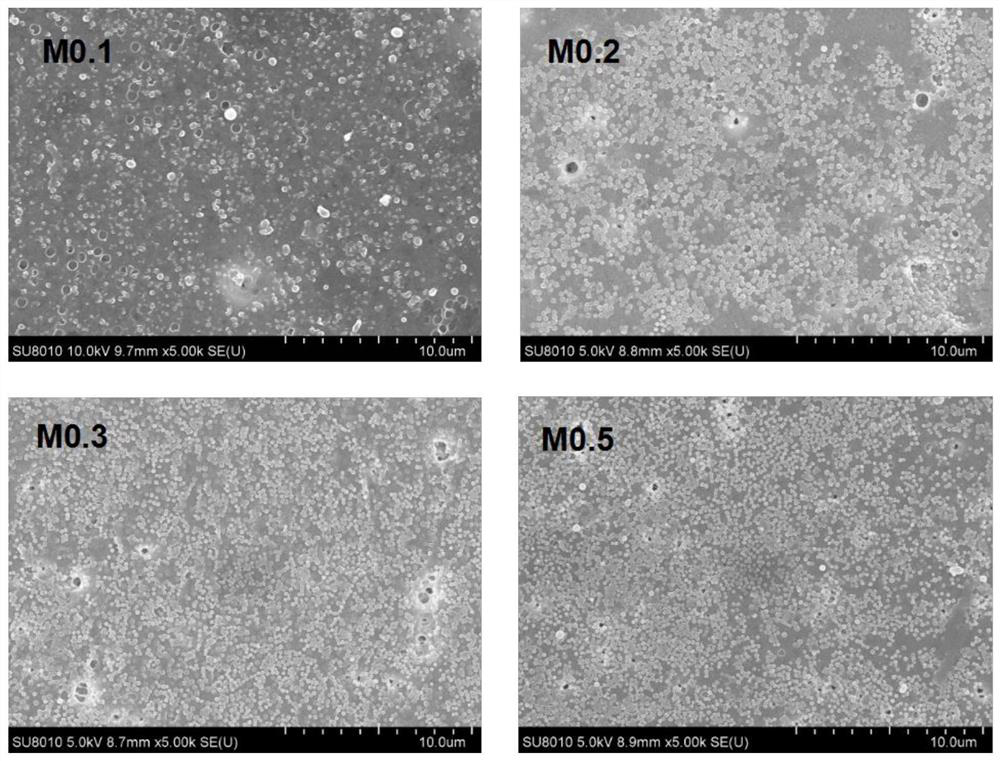

[0058] In this embodiment, the process steps of the preparation method of nanogel / polyethersulfone membrane with temperature and pH stimulus response are the same as in Example 1, the difference is only in the feed molar ratio of MAA and NIPAM in step (1) The ratio is 1:9, the resulting nanogel is labeled as Nanogel No.1, and the resulting membrane is labeled as Membrane M0.1.

Embodiment 3

[0060] In this embodiment, the process steps of the preparation method of nanogel / polyethersulfone membrane with temperature and pH stimulus response are the same as in Example 1, the difference is only in the feed molar ratio of MAA and NIPAM in step (1) The ratio is 3:7, the resulting nanogel is labeled as Nanogel N0.3, and the resulting membrane is labeled as Membrane M0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com