Model Prediction-Direct Torque Control Method for Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor and direct torque control technology, which is applied in the control field, can solve the problems of large dependence on motor parameters, slow dynamic response, and increase the amount of calculation in the control system, so as to avoid current coupling problems and eliminate integral accumulation. Error, the effect of improving the torque control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

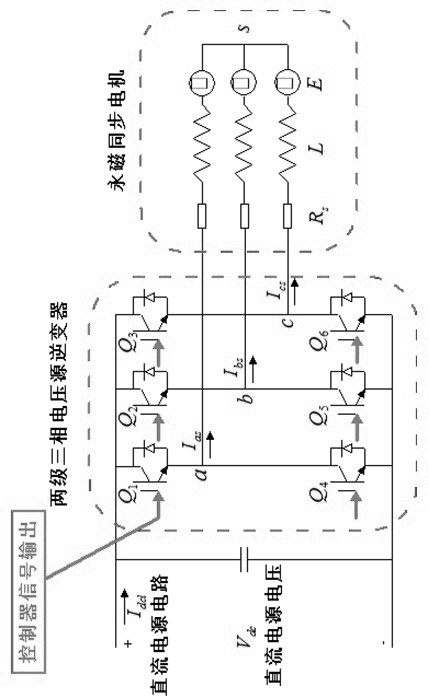

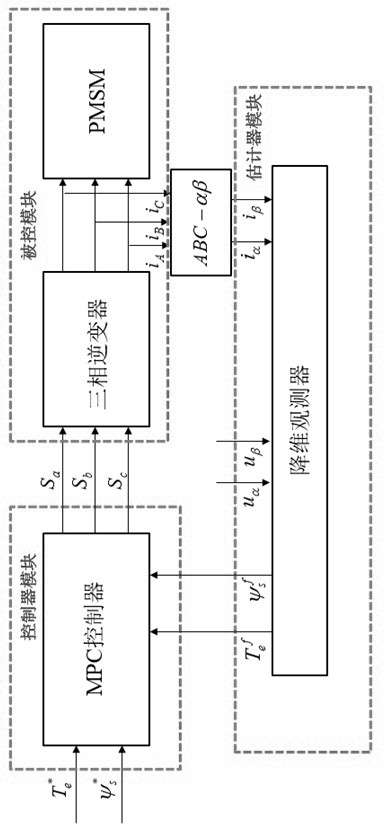

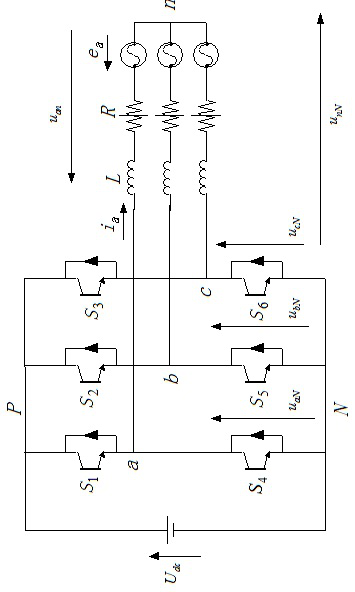

[0056] The invention relates to a model prediction-direct torque control method of a permanent magnet synchronous motor for a vehicle. Specifically, the invention relates to a model that can effectively improve the estimation accuracy of flux linkage and reduce the torque ripple of a permanent magnet synchronous motor The predictive control method improves the control effect of the inverter by compensating the dead zone of the inverter at the same time, so as to complete the fast and accurate tracking control of the given torque and meet the requirements of the electric vehicle hub motor drive control system.

[0057] The permanent magnet synchronous motor drive control system based on the model predictive control of the dead zone compensation and the dimension reduction observer designed by the present invention can well improve the above three problems. First of all, this design uses the direct torque control method as the basis. Direct torque control directly controls the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com