Carpet with silencing and denoising functions and preparation method of carpet

A technology for noise reduction and carpet, applied in the direction of carpets, polyurea/polyurethane adhesives, adhesives, etc., can solve problems such as inability to effectively absorb noise, poor sound absorption and noise reduction, and loose connection between layers, and achieve good Quiet noise reduction effect, excellent sound insulation, effect of improving bond strength and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

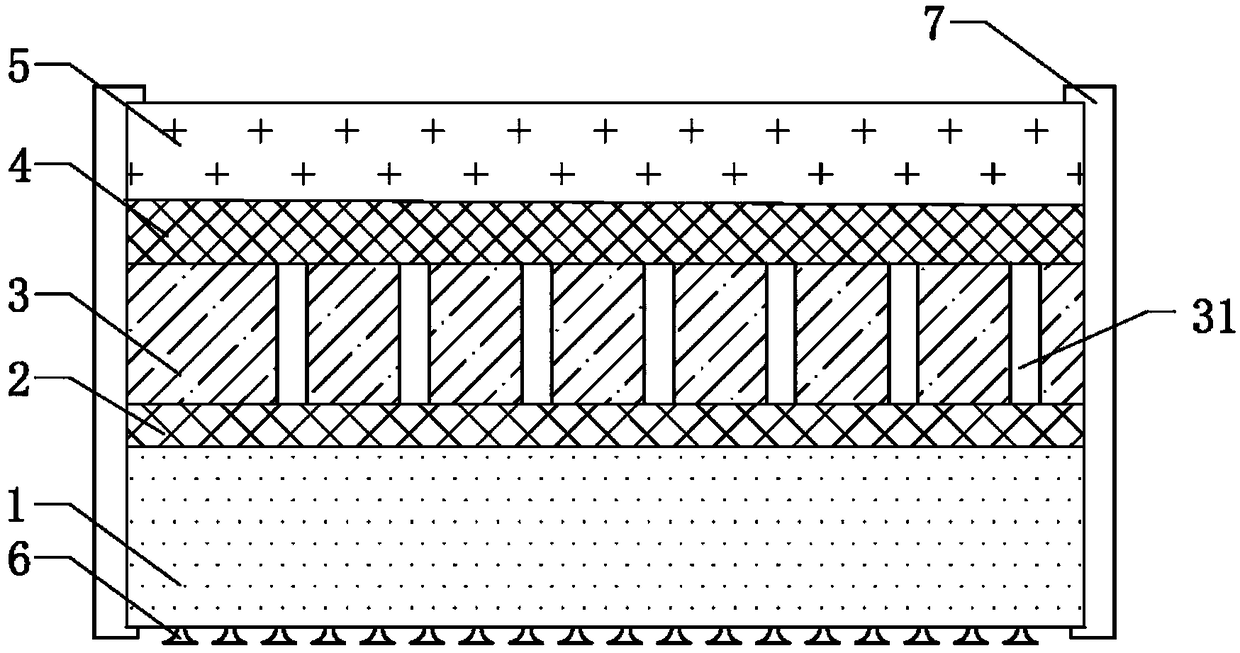

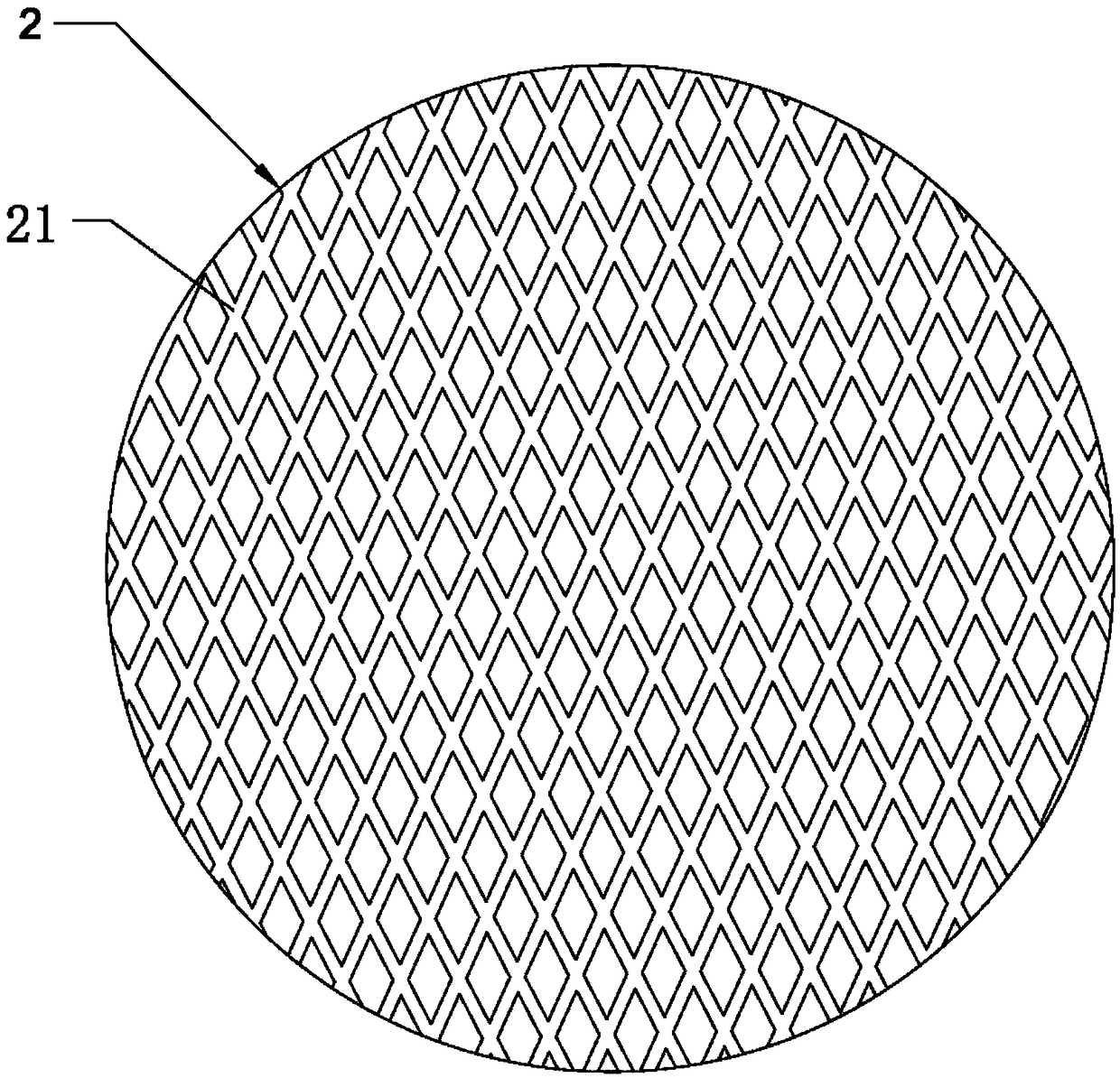

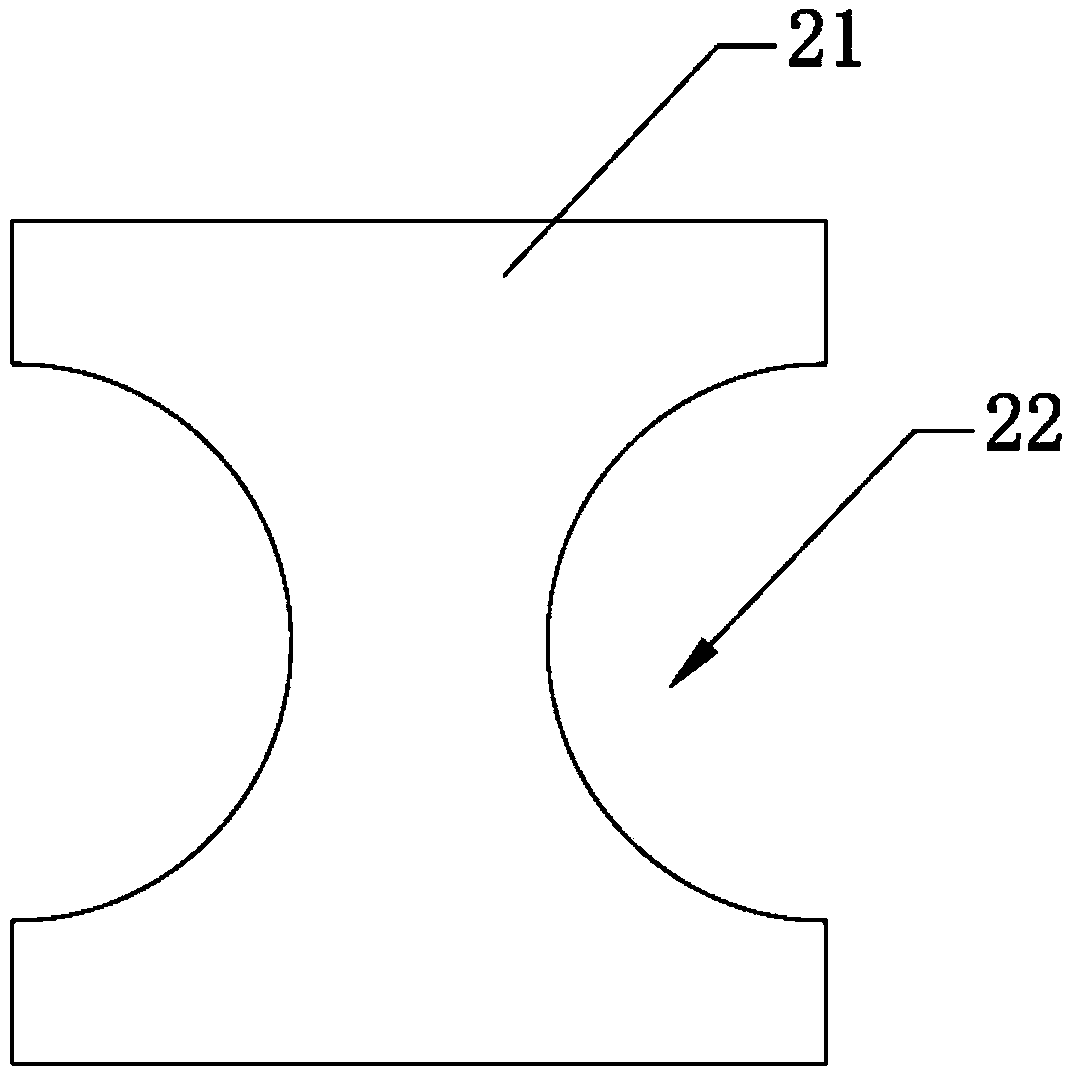

[0039]In this embodiment, a silent and noise-reducing carpet includes a wear-resistant layer, a first hot-melt adhesive mesh layer, a sound-absorbing layer, a second hot-melt adhesive mesh layer, and a braided layer arranged sequentially from bottom to top. The wear-resistant layer There are a plurality of anti-slip protrusions arranged at intervals, the upper end of the anti-slip protrusions is connected to the lower surface of the wear-resistant layer, the braided layer is woven by warp knitting threads and weft braiding threads, and the sound-absorbing The layer is a polyester fiber sound-absorbing layer.

[0040] The polyester fiber sound-absorbing layer is made of polyester fiber sound-absorbing material, and the polyester fiber sound-absorbing material includes the following components by weight: 35 parts of polyester fiber, 5 parts of carbon fiber, 5 parts of polystyrene, expanded perlite 3 parts, 2 parts of glass fiber, 0.8 parts of nano-titanium dioxide (nano-titanium...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063] In this embodiment, the polyester fiber sound-absorbing layer is made of polyester fiber sound-absorbing material, and the polyester fiber sound-absorbing material includes the following components in parts by weight: 30 parts of polyester fiber, 3 parts of carbon fiber, 3 parts of polystyrene 4 parts, 2 parts of expanded perlite, 1 part of glass fiber, 0.5 parts of nano-titanium dioxide, 1 part of nano-calcium carbonate, 4 parts of xanthan gum, 40 parts of ethylene-vinyl acetate copolymer emulsion.

[0064] The average particle diameter of the nano-titanium dioxide particles is 20-40nm.

[0065] The preparation method of the polyester fiber sound-absorbing material comprises the following steps:

[0066] (1) Mix and pulverize expanded perlite and diatomaceous earth, and sieve through a 90-120 mesh sieve to obtain mixed powder A;

[0067] (2) Add polyester fiber, carbon fiber, polystyrene, glass fibe...

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] In this embodiment, the polyester fiber sound-absorbing layer is made of polyester fiber sound-absorbing material, and the polyester fiber sound-absorbing material includes the following components in parts by weight: 40 parts of polyester fiber, 6 parts of carbon fiber, 6 parts of polystyrene 5 parts of expanded perlite, 3 parts of glass fiber, 1 part of nano-titanium dioxide (nano-titanium dioxide), 2 parts of nano-calcium carbonate, 8 parts of xanthan gum, and 50 parts of ethylene-vinyl acetate copolymer emulsion.

[0079] The preparation method of the polyester fiber sound-absorbing material comprises the following steps:

[0080] (1) Mix and pulverize expanded perlite and diatomaceous earth, and sieve through a 90-mesh sieve to obtain mixed powder A;

[0081] (2) Add polyester fiber, carbon fiber, polystyrene, glass fiber, polystyrene, and nano-calcium carbonate into a high-speed kneader, heat up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com