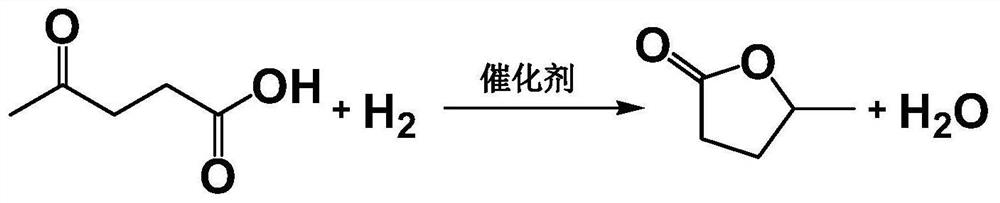

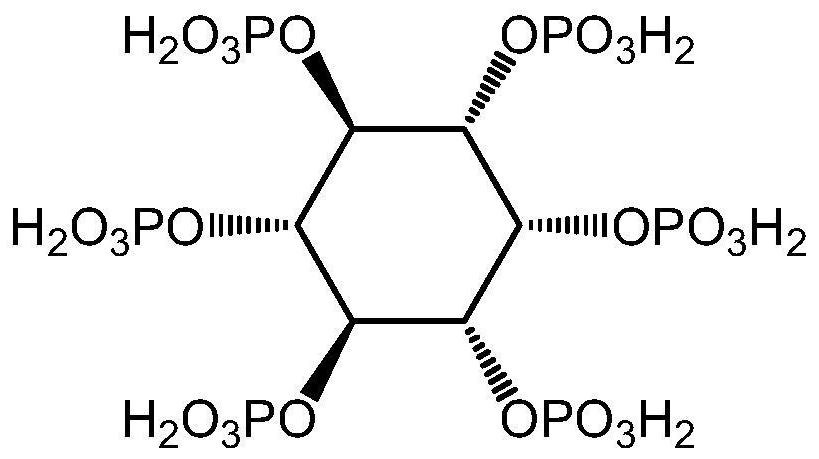

A niobium phytate-supported nano-metal catalyst system for hydrogenation of levulinic acid and esters

A technology of levulinic acid and nano-metals, applied in organic compound/hydride/coordination complex catalysts, catalytic reactions, physical/chemical process catalysts, etc., to achieve high catalytic activity, good biocompatibility, and substrate adaptation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 5 millimoles of levulinic acid and a catalyst (the amount of the nanometer metal catalyst is 5 mol% of the levulinic acid) were added into a 15 milliliter autoclave. After airtight vacuum degassing, filled with H 2 to 3MPa, and then reacted in a heating furnace at 60°C for 8 hours. After cooling and degassing, using n-dodecane as an internal standard, the yield of γ-valerolactone was detected by gas chromatography. When using Ru / niobium phytate, Pd / niobium phytate, Pt / niobium phytate, Au / niobium phytate as the catalyst and without catalyst, the yield of γ-valerolactone is shown in the table below.

[0016] catalyst Yield(%) Ru / niobium phytate 99 Pd / niobium phytate 12 Pt / niobium phytate 49 Au / niobium phytate 3 no catalyst 0

Embodiment 2

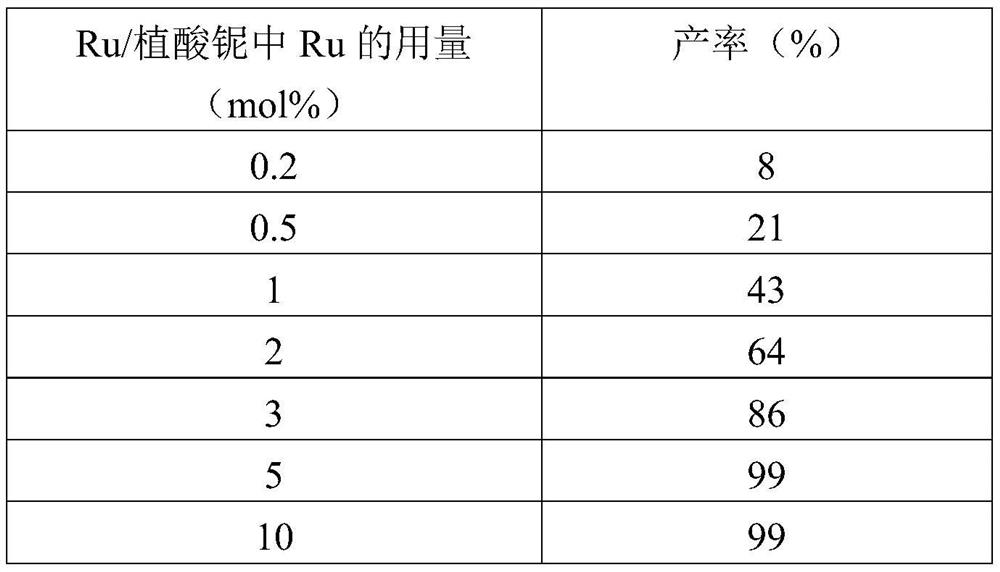

[0018] Add 5 mmol of levulinic acid and the catalyst Ru / niobium phytate into a 15 ml autoclave. After airtight vacuum degassing, filled with H 2 to 3MPa, and then reacted in a heating furnace at 60°C for 8 hours. After cooling and degassing, using n-dodecane as an internal standard, the yield of γ-valerolactone was detected by gas chromatography. When the amount of Ru is 0.2 mol%, 0.5 mol%, 1 mol%, 2 mol%, 3 mol%, 5 mol%, and 10 mol%, respectively, the yield of γ-valerolactone is shown in the table below.

[0019]

Embodiment 3

[0021] 5 mmol of levulinic acid and Ru / niobium phytate (5 mol%) were added into a 15 ml autoclave. After airtight vacuum degassing, filled with H 2 to 3MPa, and then reacted in furnaces at different temperatures for 8 hours. After cooling and degassing, using n-dodecane as an internal standard, the yield of γ-valerolactone was detected by gas chromatography. When the reaction temperature is 25°C, 40°C, 50°C, 60°C, 70°C, 80°C, the yield of γ-valerolactone is shown in the table below.

[0022] Reaction temperature (°C) Yield(%) 25 42 40 63 50 89 60 99 70 99 80 99

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com